One of Ireland's largest red meat producers

The Kepak Group is one of Ireland's largest red meat producers processing over 300,000 cattle, 1.5 million lambs and 25,000 tonnes of consumer foods per annum. The group's turnover is in excess of €750 million and they employ over 2000 people at 8 manufacturing plants located across Ireland and the UK.

Kepak has been an Emydex customer since 2006 when Emydex's production management software platform was rolled out in the group's main beef & lamb processing plant in Clonee, Co Meath.

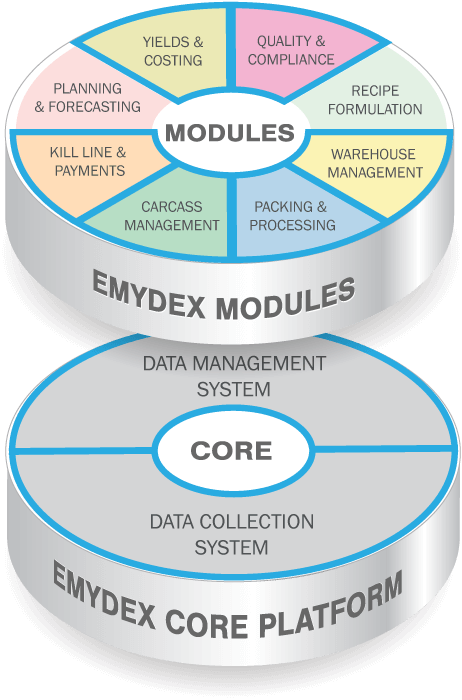

In Clonee, Emydex software monitors, controls and reports on beef production door to door from arrival at the factory gates, through kill line, carcass management, into boning, packing, and dispatch.

Emydex software has also been rolled out in Kepak's beef processing plants in Ballymahon, Kilbeggan, Athleague and Hacketstown. The system is currently being rolled out in Kepak's lamb processing plant in Cork, with Wakefield UK planned for implementation in the latter half of 2010.

What Kepak Says

"We now have complete warehouse control and real time stocks down to scan level, without having to compromise on functionality. This functionality includes real-time validation at point of scanning an order, where the Emydex system warns operators of any discrepancies that arise during picking."

Jim O'Neill, Group IT Manager, Kepak Group

Challenge

- Production & billing systems built In-house

- Not integrated

- Over-reliance on a few key individuals

- High cost of maintaining & updating systems

- Low level of support

- No real-time reporting on Stocks, Traceability, Yields & Costs

Solution

Outcome

- Data capture system, end-to-end across all 14 group factory sites

- Inter-site Transfers, Stock movements

- Fully integrated to Microsoft Dynamics AX

- Ability to handle catch-weights as well as standard weights

- Real-time production reporting on Yields, Stock and Traceability information

Our News

Industry Updates

Farmer Bookings & Feedback via Livestock Portal

A new web-based appointment booking and feedback system.

Find Out MoreEmydex CAPS off year with Livestock Payments System

Emydex CAPS off the year with a new Livestock Settlements System For most Meat processors, the procurement of…

Find Out MoreTurning over a new leaf in New Zealand

Turning Over A New Leaf In New Zealand How Emydex helped the largest livestock processing company in New…

Find Out MoreEliminate costly carton rejections with Emydex and Meat Messaging

The international trade of food products has over time become highly competitive with many large multinational companies emerging…

Find Out MoreImprovements by the country mile

Meet the client Ashbourne Meat Processors is one of Ireland’s most successful exporters of premium chilled beef products….

Find Out MoreSunPork scales new heights

Meet the client Through Swickers Kingaroy, SunPork is the largest pig processor in all of Australia, handling 900,000…

Find Out More