Emydex food processing software

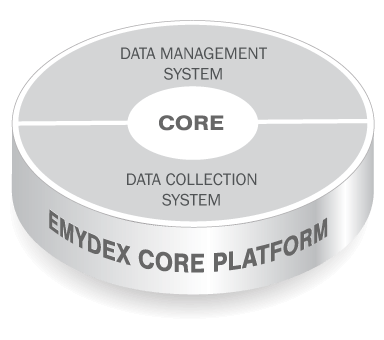

The Emydex Core Platform is a common code-base that is implemented as standard across our entire customer base. The Core Platform consists of 2 main components, the Data Collection System (DCS) and Data Management System (DMS)

Emydex Explained

Our software provides real-time and accurate reporting of Production, Yields, Stocks, Quality and Traceability

Emydex Software

How does it work?

Data Collection System (DCS)

Emydex collects data from the factory floor at various Control Points in the production process using a variety of data capture devices.

- Data Collection Terminals

- Barcode reader (eg Symbol or Intermec)

- Weighing Scales (eg Avery, Marel, Scanvaegt, Bizerba, GSC, Ian Fellows)

- Mobile Hand Scanners (such as Symbol/Motorola, Intermec)

- Printers (eg as Intermec, Zebra, Datamax)

- RFID Reader (eg as Symbol, Sick)

- Controls (eg Sick)

- Auto-Graders

- I/O Boards

Data Management System (DMS)

Once data has been collected from the factory floor, the Emydex Data Management System handles data processing and data exchange, and is used to analyse & report on production

- Data Reporting & Analysis

- Data Maintenance (PLU file maintenance, manual entry…)

- System Configuration (Users, Profiles, Security, Labels)

- Integration (3rd party systems eg Financial, ERP, 3rd Party storage)

Designed for your industry

Our software modules

The Emydex suite of software includes a collection of independent standalone software modules designed to manage and control a particular stage of the Food Production Process e.g. Kill Line & Payments.

Each modules sits on top of the core platform, and can plug seamlessly into any other module. The full suite of modules cover all aspects of Food production from factory door-to-door.