Traceability Reporting Software

Traceability is one of the most important fundamental requirements for any food production facility. Being able to quickly and effortlessly trace product backwards or forwards whilst ensuring it is accurate is vital.

Traceability is inherited within each module of the Emydex platform and is designed to reduce the size of potential recalls and uses the Emydex reporting functions to provide instant traceability reports. Emydex system is able to provide various methods and levels of traceability depending on your factories processes.

Traceability Reporting

Benefits of our System

Traceability Reporting

System Features

One Step Back – One Step Forward

As a minimum requirement for traceability is to record one step back and one step forwards in the traceability chain. This could be recording from which abattoir or supplier an animal, carcass or primal was received from and when it was received.

Forwards Traceability

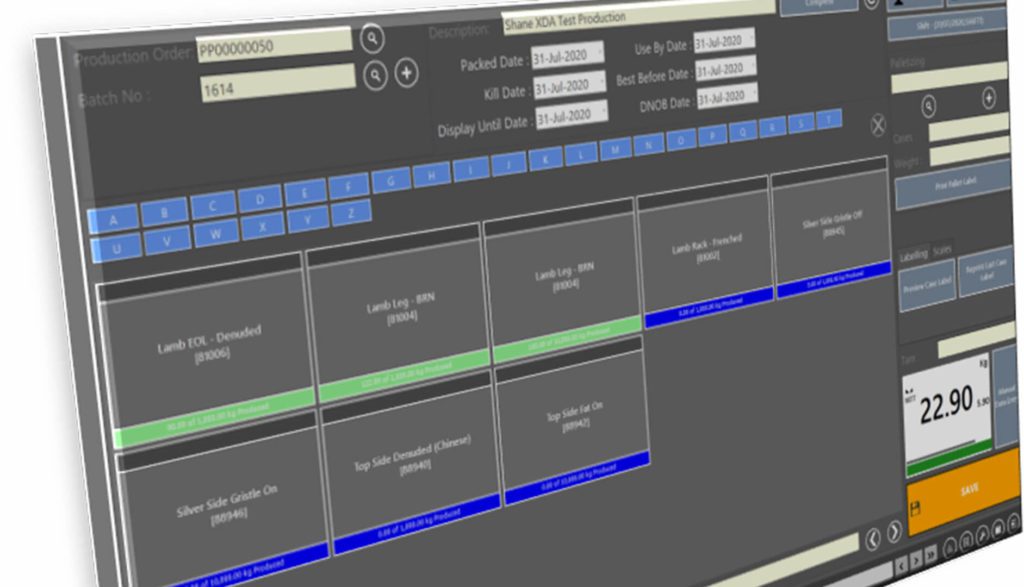

Forwards traceability allows customers to report on details of every production transaction taking place within the factory. Forward traceability grids allow users to search for purchase order (PO) number and see all the product that was received against the PO. They can then see which sales order the product was dispatched to and every step of the process in between.

Backwards traceability

Backwards traceability allows customers to report on details of every production transaction taking place within the factory. Backward traceability grids allow users to search for a Sales/Transfer order and see all the product that was dispatched against the order. They can then see which purchase order or kill lot the product was received against and every step of the process in between.

Time-Bound Traceability

Emydex traceability reporting allows for time-bound traceability, where customers know when a certain product entered a process and know how long it takes for the product to exit the process. This will then show all the transactions within the defined period.

Batch Traceability

Batches can be set up in advance of production or created on the fly on the factory floor. Product can be scanned into these batches and product produced from these batches. At times this can be a many to many relationships, however, the Emydex traceability reporting allows for customers to maintain and simply report on the traceability of product.

Designed for your industry

Our software modules

The Emydex suite of software includes a collection of independent standalone software modules designed to manage and control a particular stage of the Food Production Process e.g. Kill Line & Payments.

Each modules sits on top of the core platform, and can plug seamlessly into any other module. The full suite of modules cover all aspects of Food production from factory door-to-door.

Emydex Explained

Our software provides real-time and accurate reporting of Production, Yields, Stocks, Quality and Traceability

Our News

Industry Updates

Emydex 20 years – Clogherhead Co-op

Clogherhead Co-op Seafood Primal Processor, 1 Co-operative plant, 12 trawlers, Ireland Emydex customer from 2014 – 2024 (10…

Find Out MoreEmydex 20 years – Central Agri Group

Central Agri Group Beef Primal Processor1 Plant in Victoria, Australia Emydex customer from 2016 – 2024 (8 years)…

Find Out MoreEmydex 20 years – Silver Ferns Farms

Silver Fern Farms Beef & Lamb Primal Processor 14 plants, New Zealand Emydex customer from 2010 – 2024…

Find Out MoreEmydex 20 years – Wilson Hellaby Ltd

Wilson Hellaby Ltd Beef & Lamb Primal Processor 2 plants, New Zealand Emydex customer from 2015 – 2024 (9 years)…

Find Out MoreEmydex 20 years – QK Coldstores

QK Coldstores (Pty) Ltd Coldstore, 1 plant, South Africa Emydex customer from 2017 – 2024 (7 years) “We are delighted…

Find Out MoreEmydex 20 years – Canfisco

Canadian Fishing Company (Canfisco) Seafood Processor, 4 plants, British Columbia, Canada Emydex customer from 2017 – 2024 (7…

Find Out MoreEmydex 20 years – Ashbourne Meats

Ashbourne Meats Beef Primal Processor, 2 plants in Ireland Emydex customer from 2016 – 2024 (8 years) “Ashbourne…

Find Out MoreEmydex 20 years – Harvey Beef

Harvey Beef Beef Primal Processor 1 Plant in Harvey, Western Australia Emydex customer from 2015 – 2024 (9…

Find Out More