Customer Survey Results

In March 2018, Emydex conducted a customer survey looking for feedback on New Product Development from key Emydex users within our existing customer community.

The survey queried customer interest levels in ten potential new products Emydex will potentially develop, to gauge interest in the products themselves and willingness to be part of the product design, validation and testing processes including:

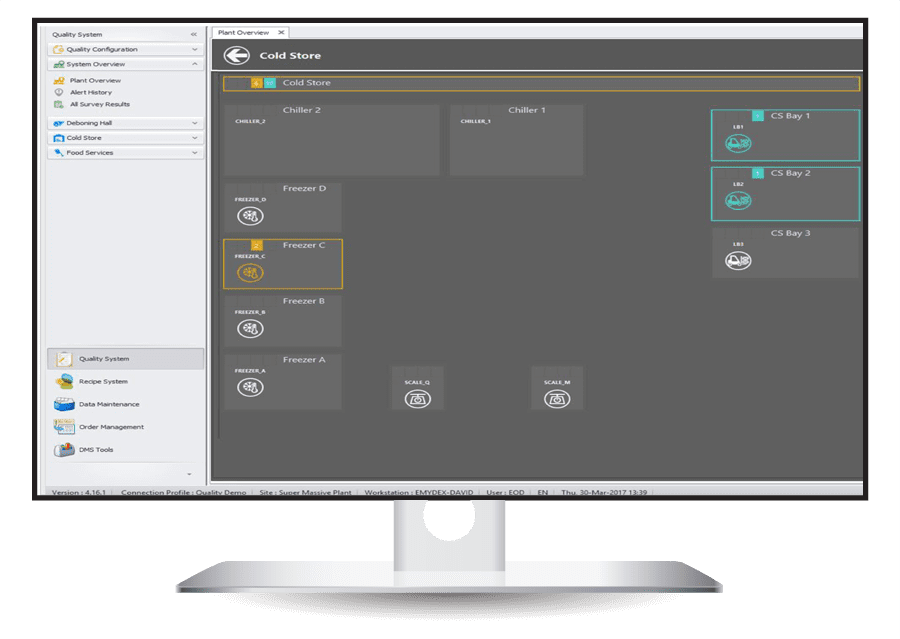

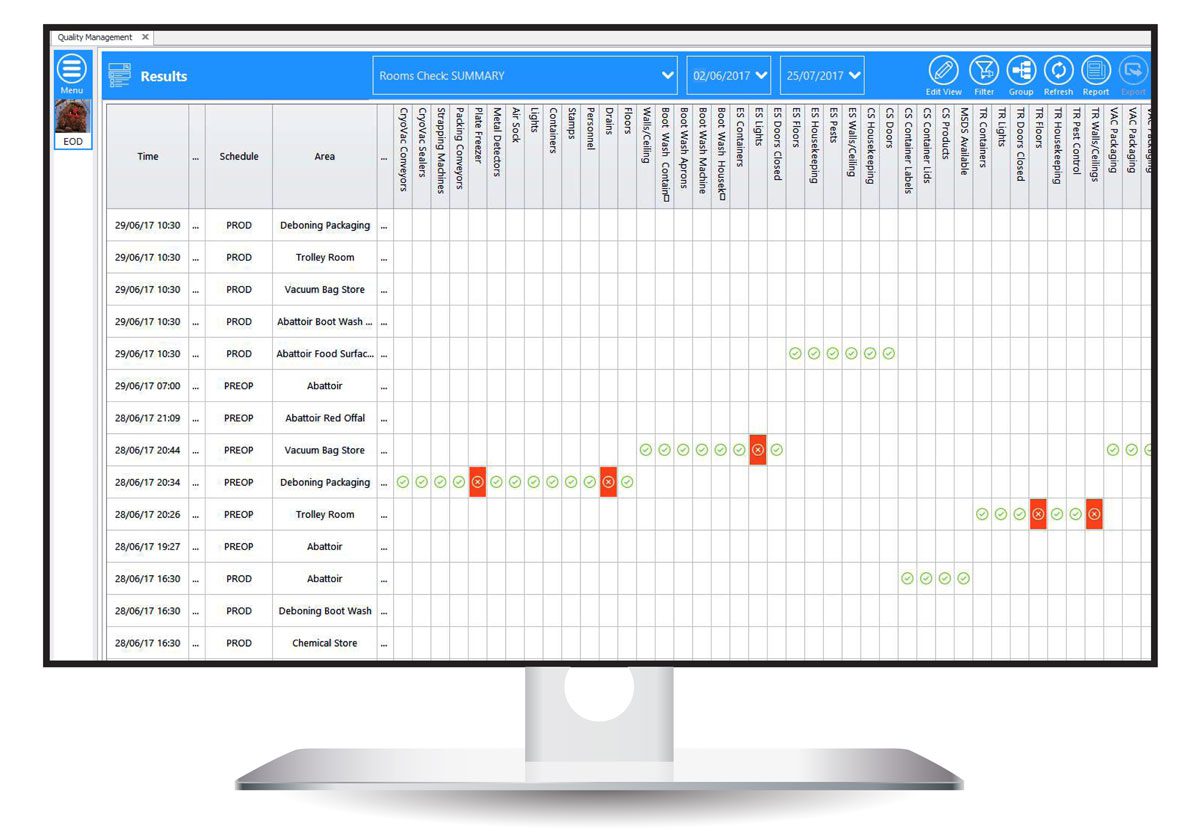

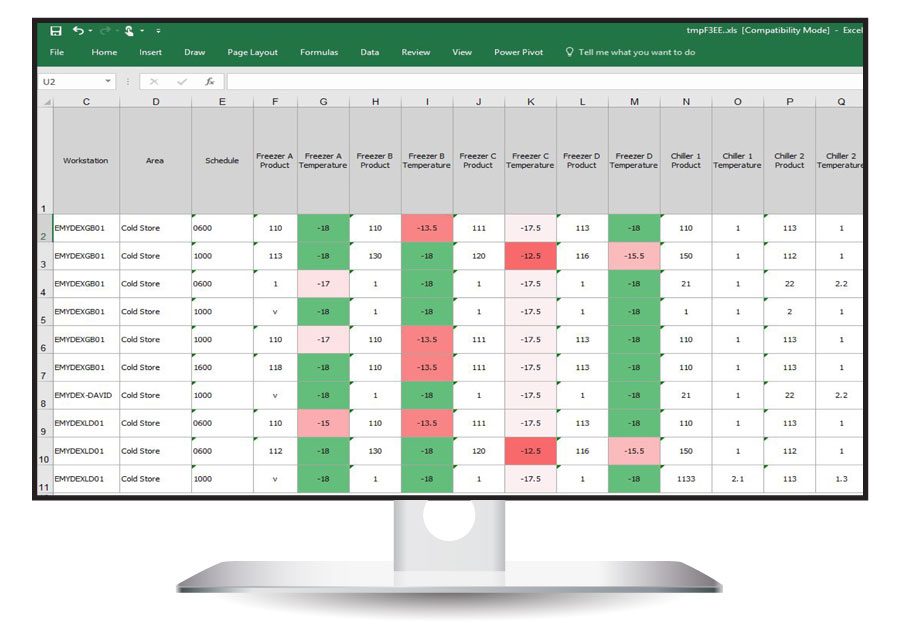

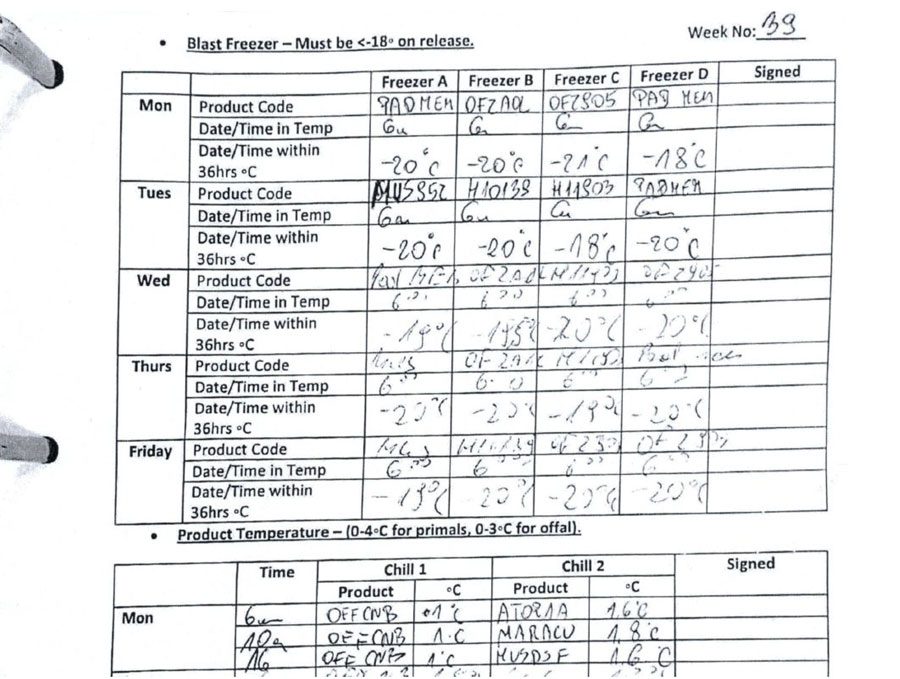

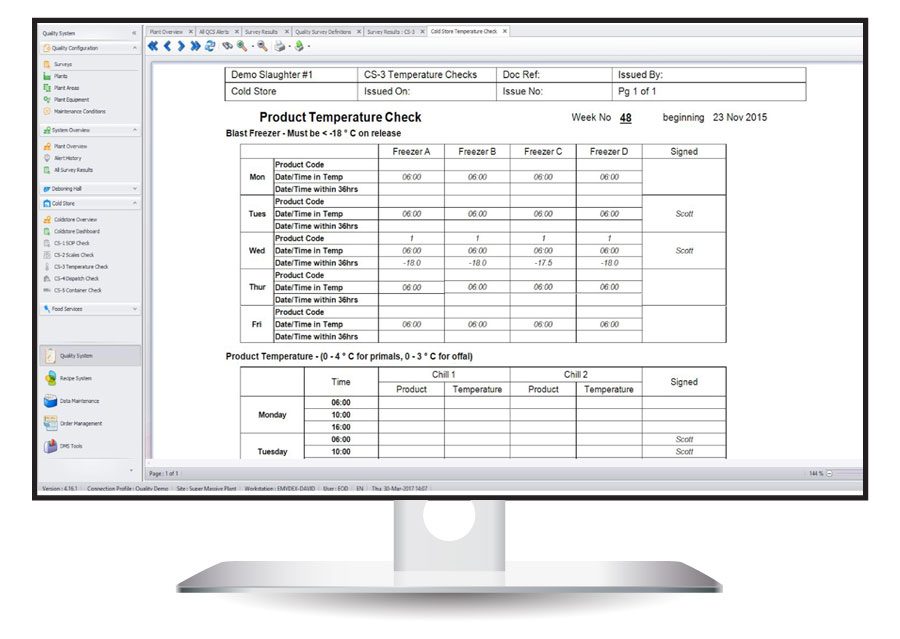

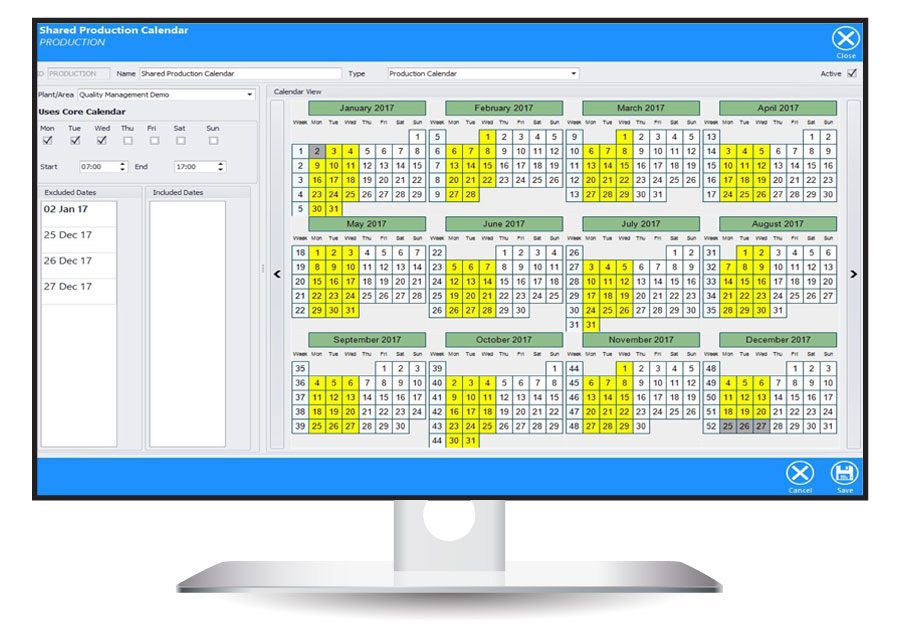

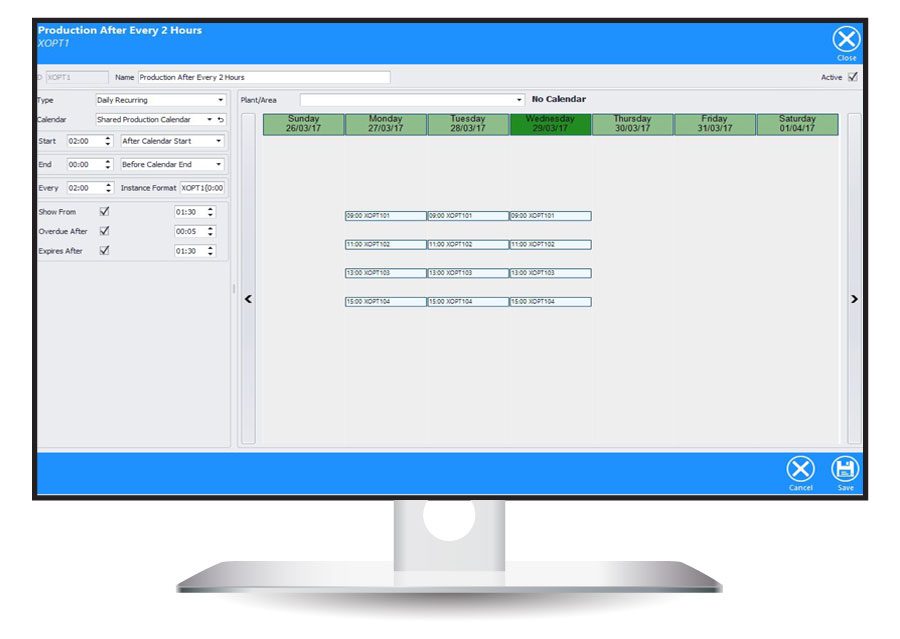

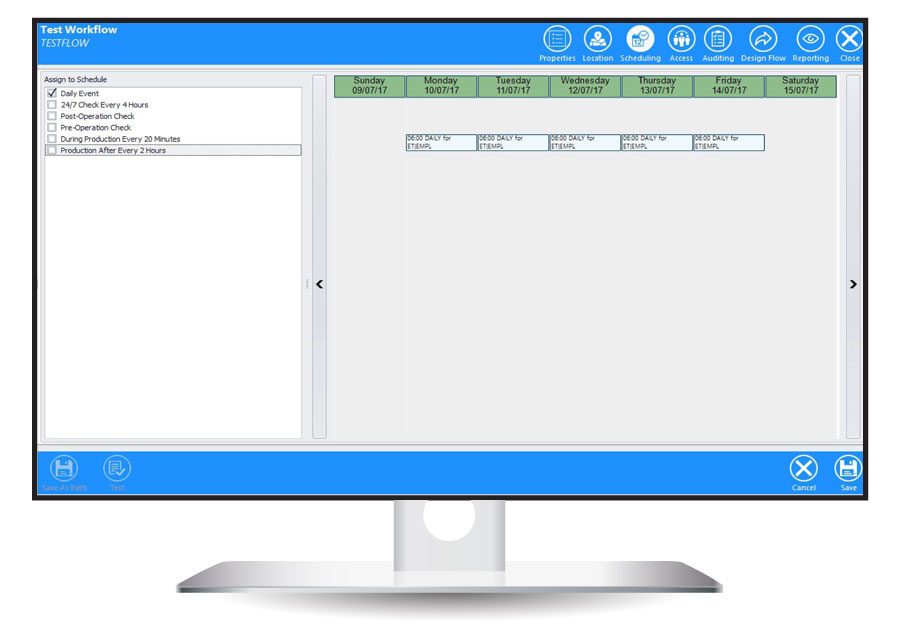

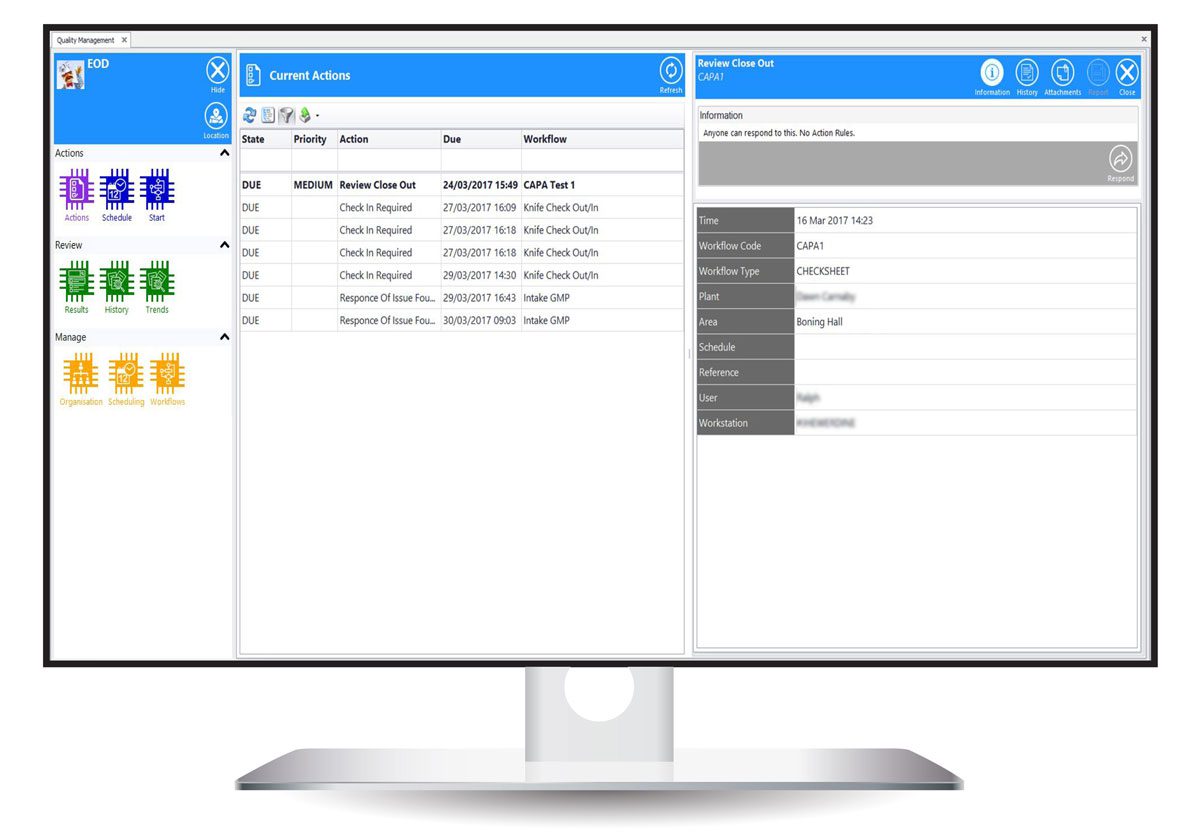

- Emydex Quality Management System (EQMS) – complete and live with customers

- Emydex Product Specification System

- Emydex Group-Wide Animal Payments System

- Emydex Production Planning System – under development

- Emydex Enterprise Master Data Management

- Emydex Demand Planning & Forecasting System

- Emydex Leaker Tracker System

- Emydex Centralised Consolidated Reporting System

- Business Intelligence & Data Analytics using MS Power BI

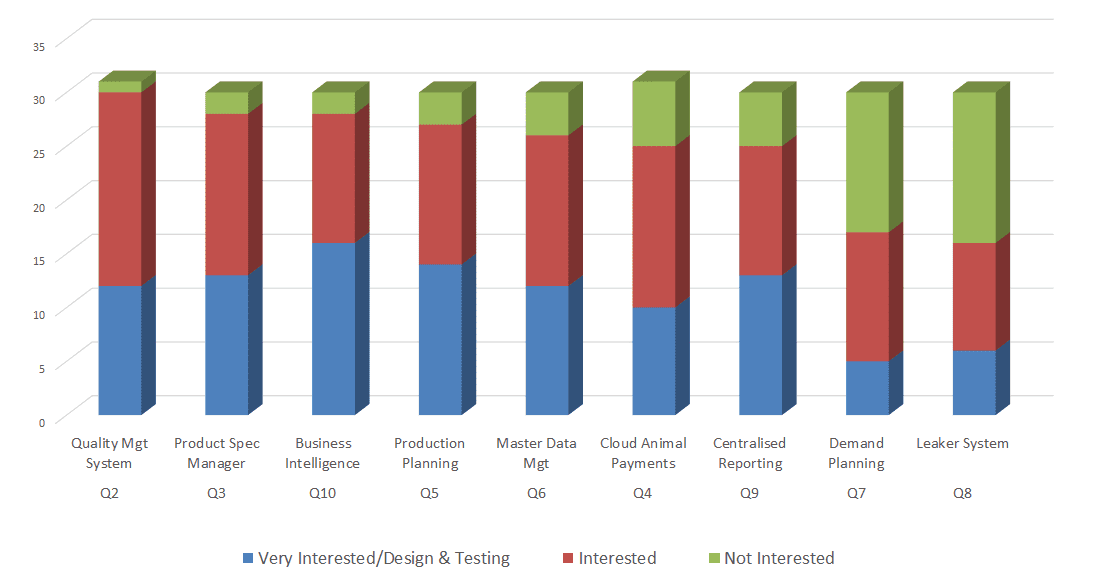

The survey results are highlighted below, summarising the products customers are most interested in seeing us develop in the future:

1st place

EQMS system with 97% of customers who responded either (1) very interested/willing to assist with design and testing or (2) interested, please keep me updated.

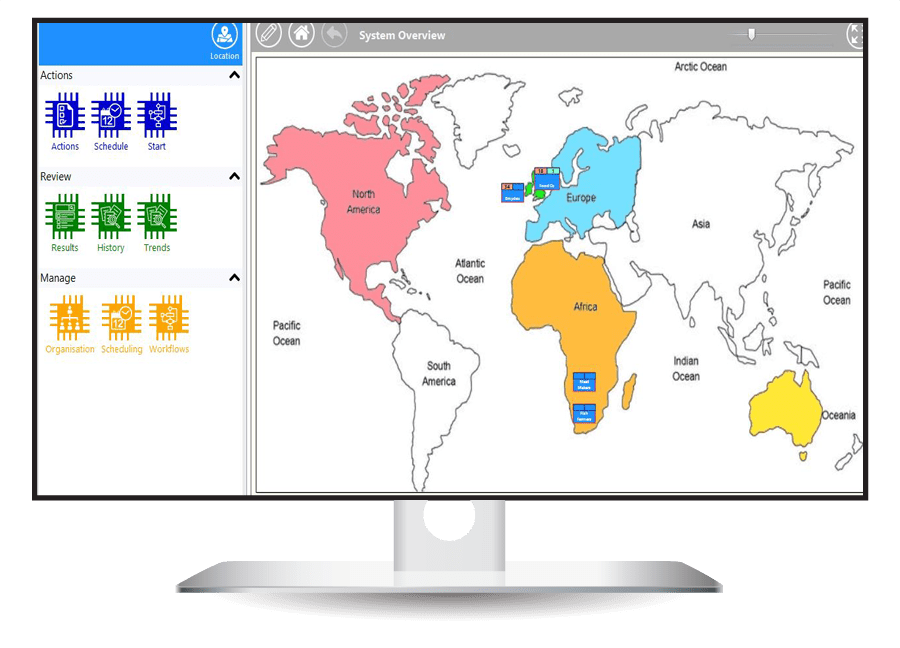

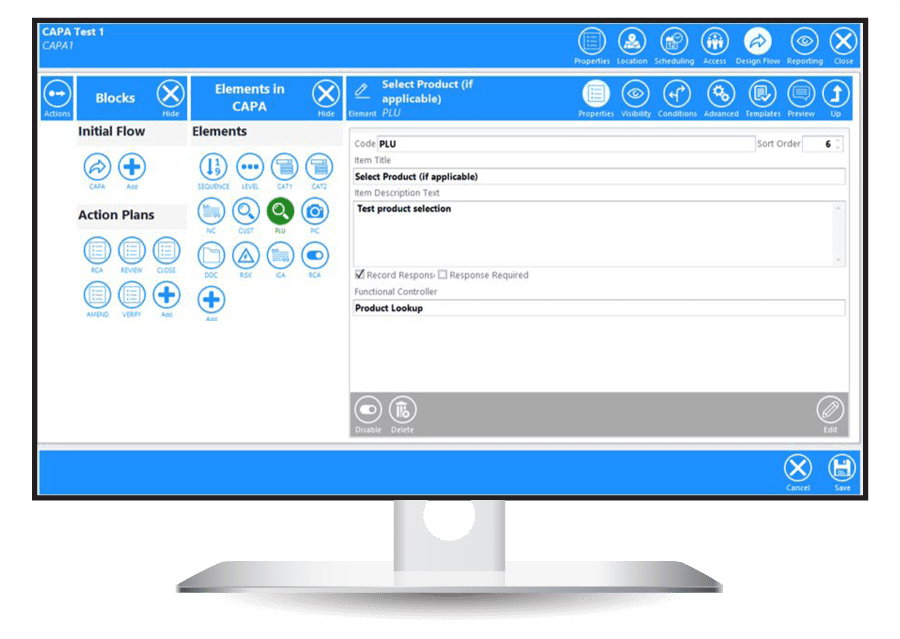

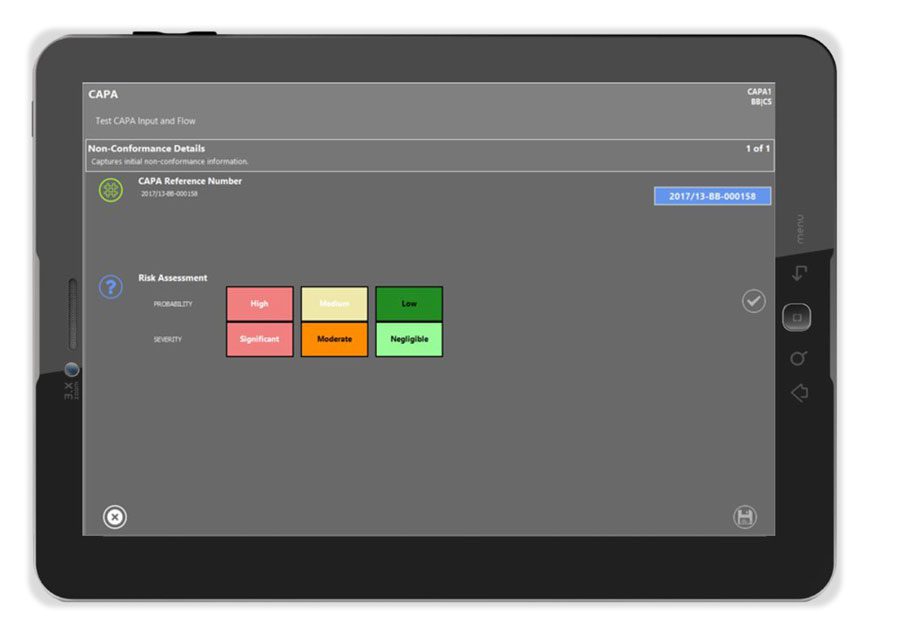

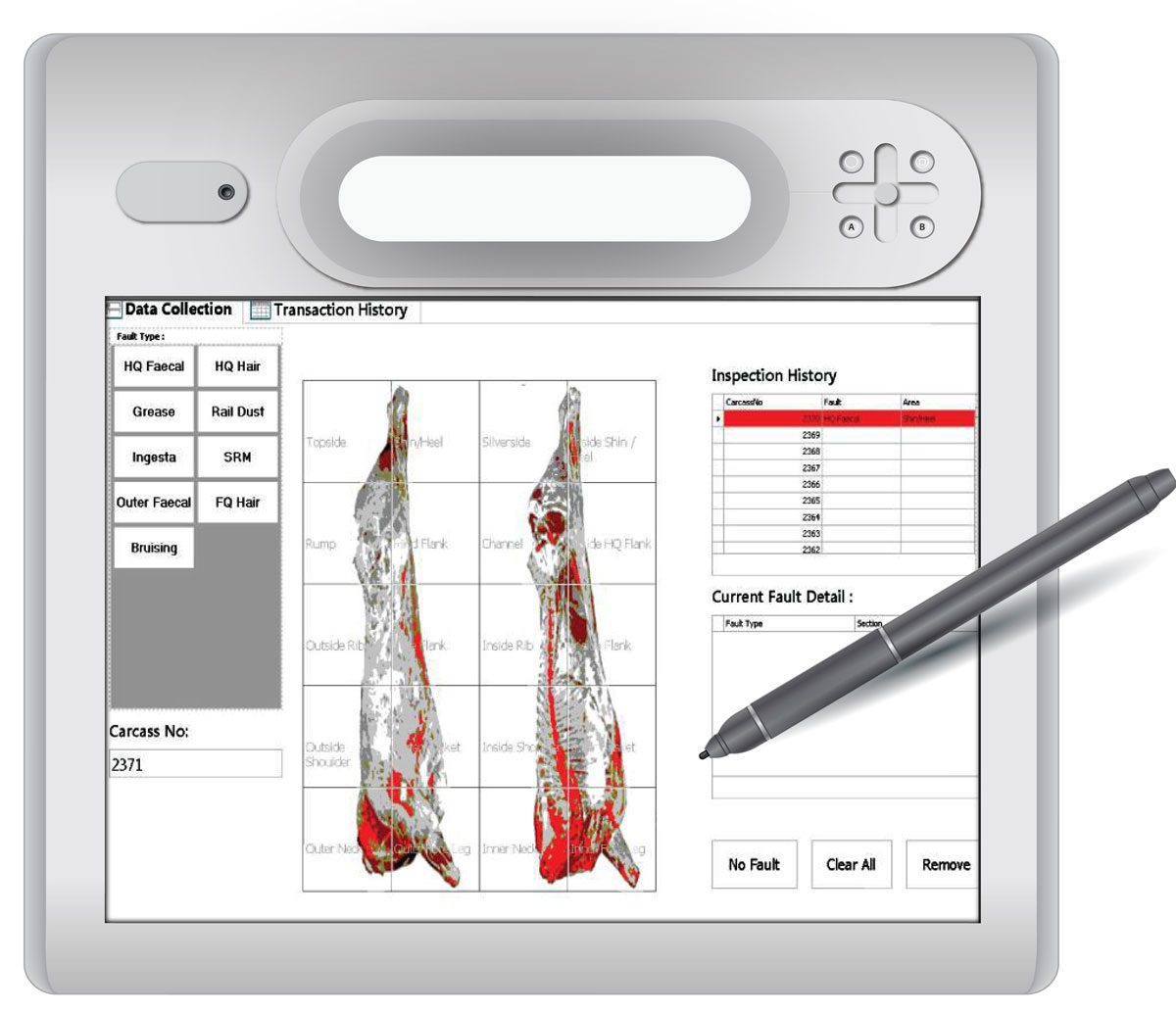

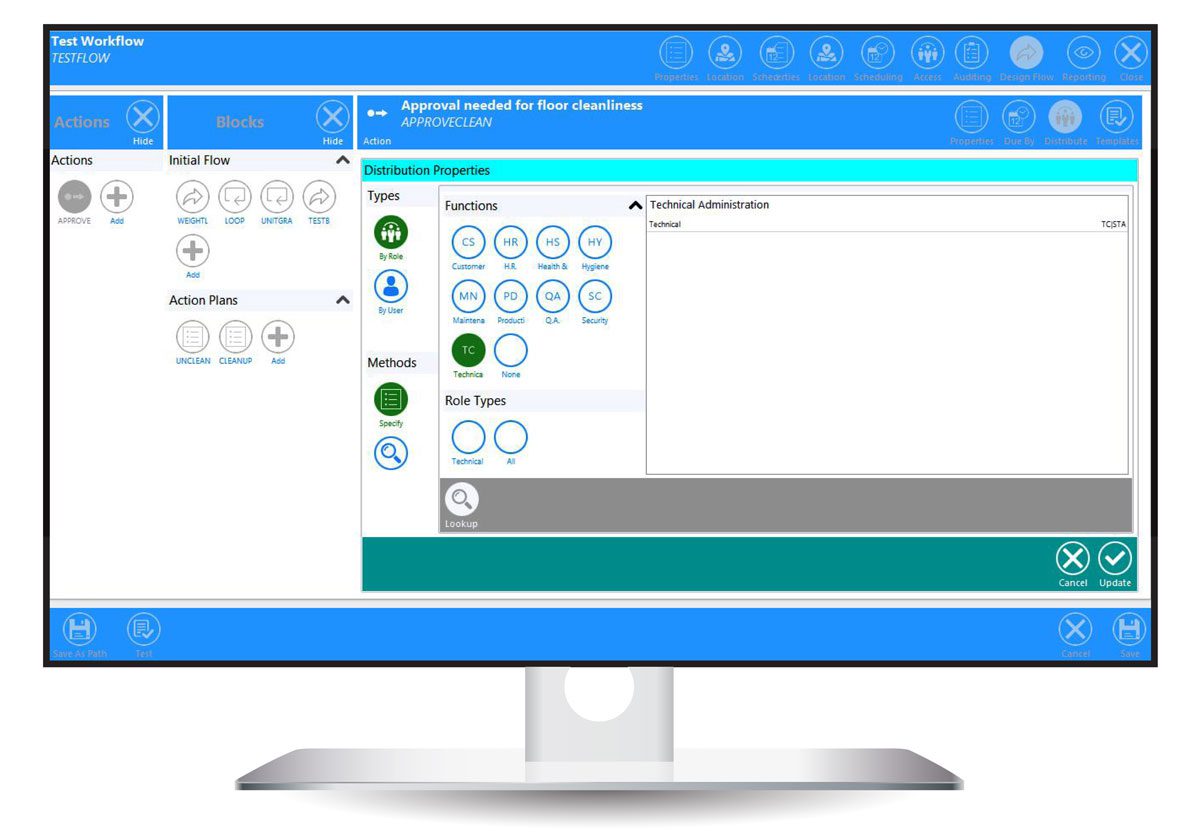

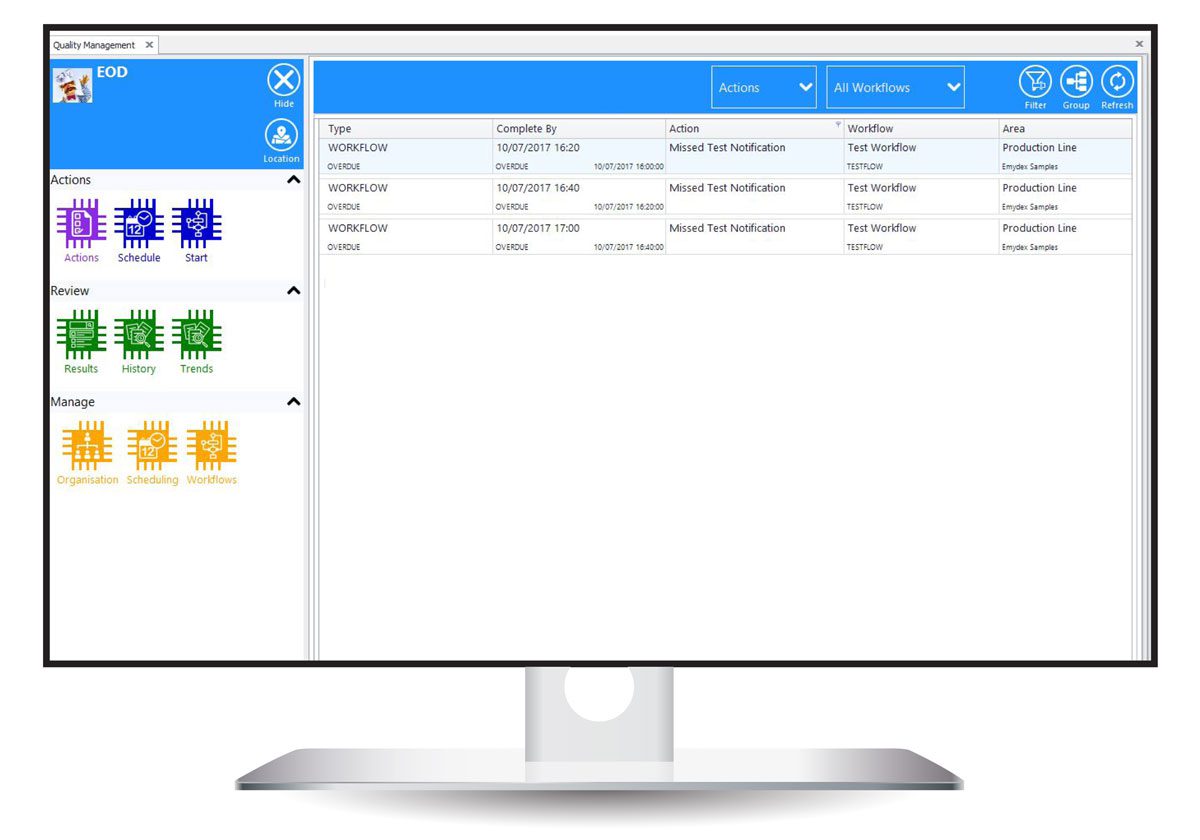

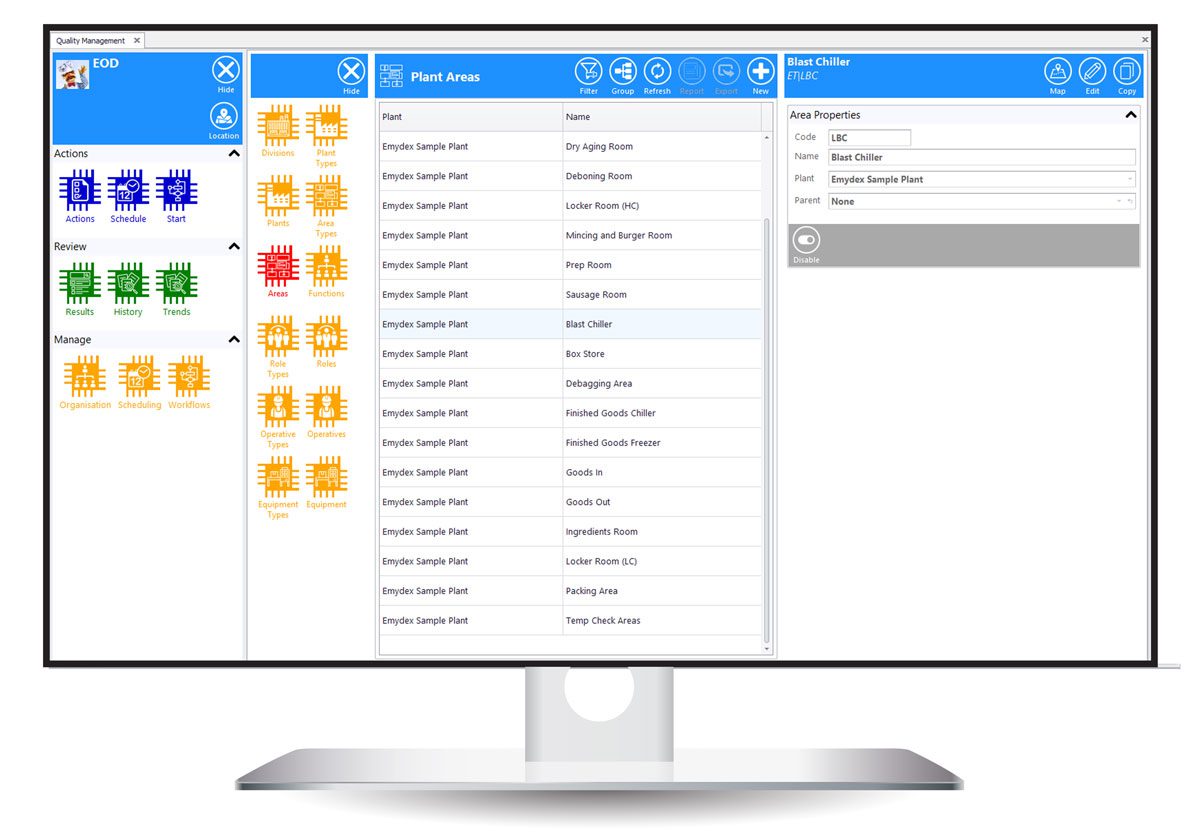

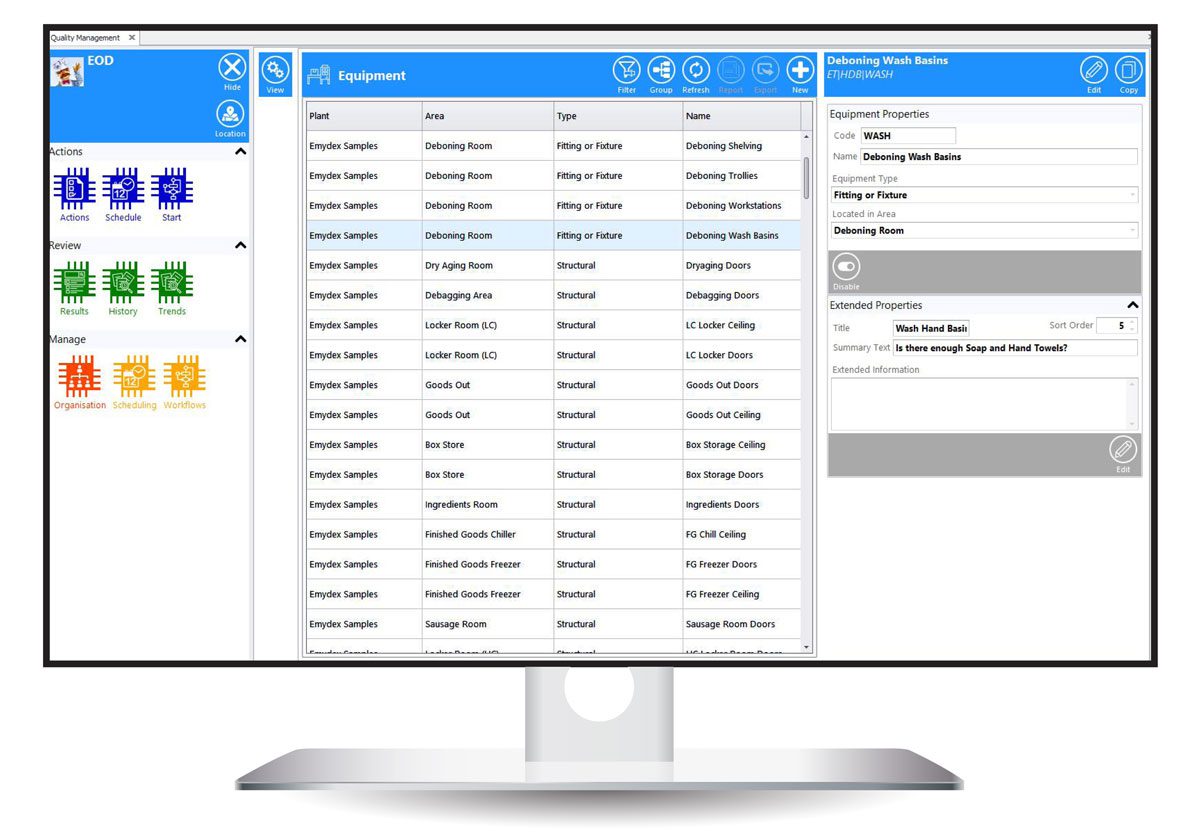

Emydex have developed a centralised QMS solution providing for all quality & compliance needs in one place, suitable for single or multi-site operations.

Joint 2nd place

Product Specification Management system and Business Intelligence with 93% of customers either very interested/willing to assist with design and testing or (2) interested, keep me updated.

Business Intelligence also had the highest single score for Very Interested/ willing to assist, with just over half of all survey respondents willing to participate in the design and testing.

Product Specification Management system – A centralised data storage solution for product specifications, such as raw materials, ingredients, packaging and finished goods, alerting internal and external partners of changes to the product spec.

Business Intelligence - Host & utilize the power of Power BI, that allows the creation of user-definable dashboards, pulling data from many sources and performing data analytics, accessing data via web based and mobile devices.

4th place

Production Planning with 90% of all customer respondents either very interested or interested, keep me updated.

Generate Production Plans based on sales demands & stock levels, using multi-tiered Bill-of-Materials. Calculate material & packaging requirements, with scheduling, capacity planning and cost calculations.

5th place

Master Data Management on 84%.

Setup & maintain all master data in one location, such as Products, Label Designs & Bill-of-Materials, with full auditing & version control and management over publishing of master data to the group’s individual plants.

Joint 6th place

Cloud Animal Payments and Centralised Reporting, with 83% either very interested or interested, keep me updated.

Cloud Animal Payments - Cloud-hosted Animal payments system for multiple production sites, with central booking system & multi-currency support.

Centralised Reporting - Bring all plant level data into one place in a consistent and consolidated state to allow group wide reporting and data archiving.

8th place

Demand Planning with 56% either very interested or interested, keep me updated.

Generate long term demand planning & forecasting for sales and material requirements, across multiple plants by looking at historical trends and strategic plans.

9th place

Leaker Tracker System with 53% either very interested or interested, keep me updated.

A system that will give you the ability to record and report vacuum pack leakers in real time the way you want!

Capturing this data will allow you to find root causes of leaking vacuum-packed products, test and track new trail packing, save money on packaging waste and reduce claims from customers.

Apple iPad Winner

As part of the survey, we placed all customer respondents into a draw to win an Apple iPad. The winner (pictured below) was Paul Reid from Rosderra Irish Meats.

David McMahon, Emydex CEO (right) presenting Apple iPad to Paul Reid (left).

For more information on any of our products or if you would like to participate in any of the mentioned New Product Development projects please contact Shane Hayes in Emydex on:

+353 1 8855990 or email Shane on shane.hayes@emydex.com