In the food processing industry, traceability is no longer just about compliance. For leaders, it is a strategic capability that directly impacts ROI, brand trust and operational resilience.

Yet many processors still rely on outdated or fragmented systems, exposing themselves to risks that are avoidable. If your business cannot trace a product by batch, shift, supplier or site instantly, you are likely facing more than just inefficiency.

1. Product Recalls

According to Consumer Brands Association, the average cost of a product recall is 10 million dollars. That does not include damage to brand reputation or customer relationships.

Without real-time traceability, identifying and isolating affected batches becomes slow and imprecise. The longer it takes to act, the greater the exposure.

2. Regulatory Non-Compliance

Many countries enforce strict regulations regarding food traceability. Failure to comply with these requirements can lead to legal penalties, failed audits, loss of operating licenses and serious reputational damage.

As outlined by the Food Safety Institute, traceability is a core pillar of modern food safety management, and weak systems are a risk few businesses can afford to take.

3. Increased Risk of Fraud

Lack of traceability opens the door to fraudulent activities, including mislabelling, product substitution or deliberate manipulation of records. These practices threaten not only food safety, but also consumer trust and business credibility.

Robust traceability systems help protect against intentional and unintentional breaches by increasing transparency and accountability throughout the supply chain.

4. Damaged Brand Trust

In today’s global food industry, transparency builds competitive advantage. Customers, partners and regulators expect clear, real-time data that supports both traceability and accountability.

One traceability gap can compromise years of brand investment and erode long-standing relationships.

Smart Investments in Traceability in Food Processing

Top-performing food processors treat traceability as part of their strategy. They invest in:

- Real-time traceability

- Traceability across sites

- Batch-level traceability

- Audit-ready traceability

This level of visibility allows them to mitigate risk, act faster, and strengthen performance across every plant.

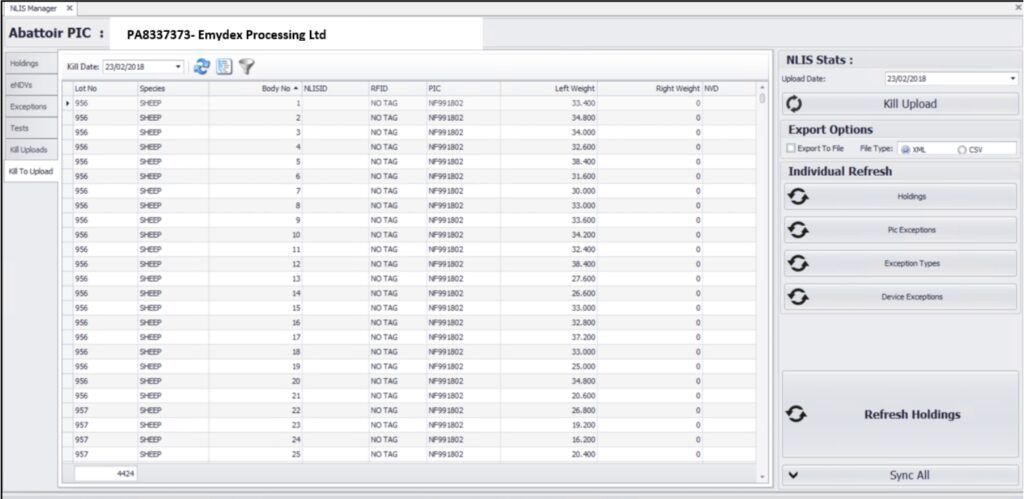

How Emydex Helps

The Traceability Reporting module from Emydex is designed specifically for food processors operating in complex, multi-site environments.

It gives your team fast, accurate and reliable traceability, without manual searching or data gaps. With Emydex, you can:

- Run full trace reports in seconds

- Filter by product, supplier, time or location

- Investigate incidents while production continues

- Meet audit and compliance requirements with confidence

And because it is part of the wider Emydex platform, it integrates seamlessly with MES, ERP and quality systems for total control.

Time to Take Control

If your current traceability system is slowing your team down, exposing your business to risk, or making compliance more difficult than it should be, it may be time to rethink the strategy.

At Emydex, we help food processors simplify traceability across complex operations, providing the visibility, speed and confidence your teams need.

To learn more, contact Emydex at any of our global market offices in Ireland, Australia, New Zealand, South Africa or North America.