The international trade of food products has over time become highly competitive with many large multinational companies emerging to satisfy the demand for the supply of high quality, safe and affordable products.

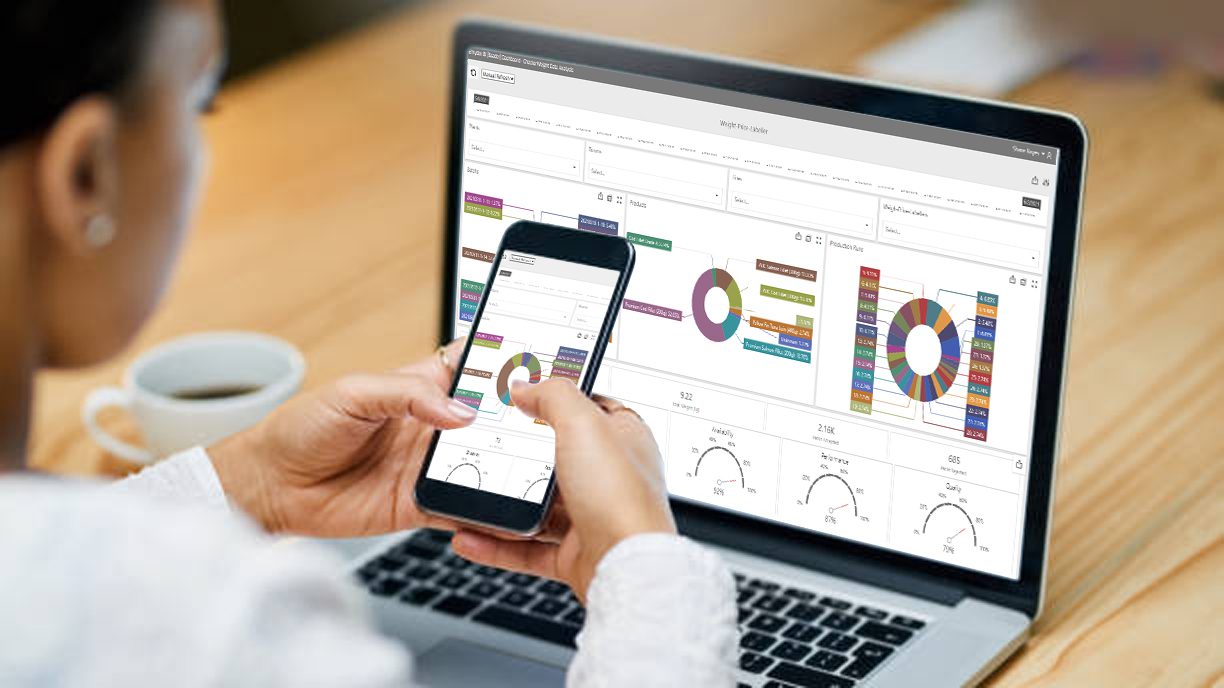

In competitive market conditions, the access to export markets is being increasingly underpinned by effective and transparent traceability, quality and food safety compliance and proof of authenticity and origin. To better fulfil these requirements, innovative integrated software systems that can easily adapt to changing regulatory environments is key to securing access to these markets and increasing efficiency across the value chain.

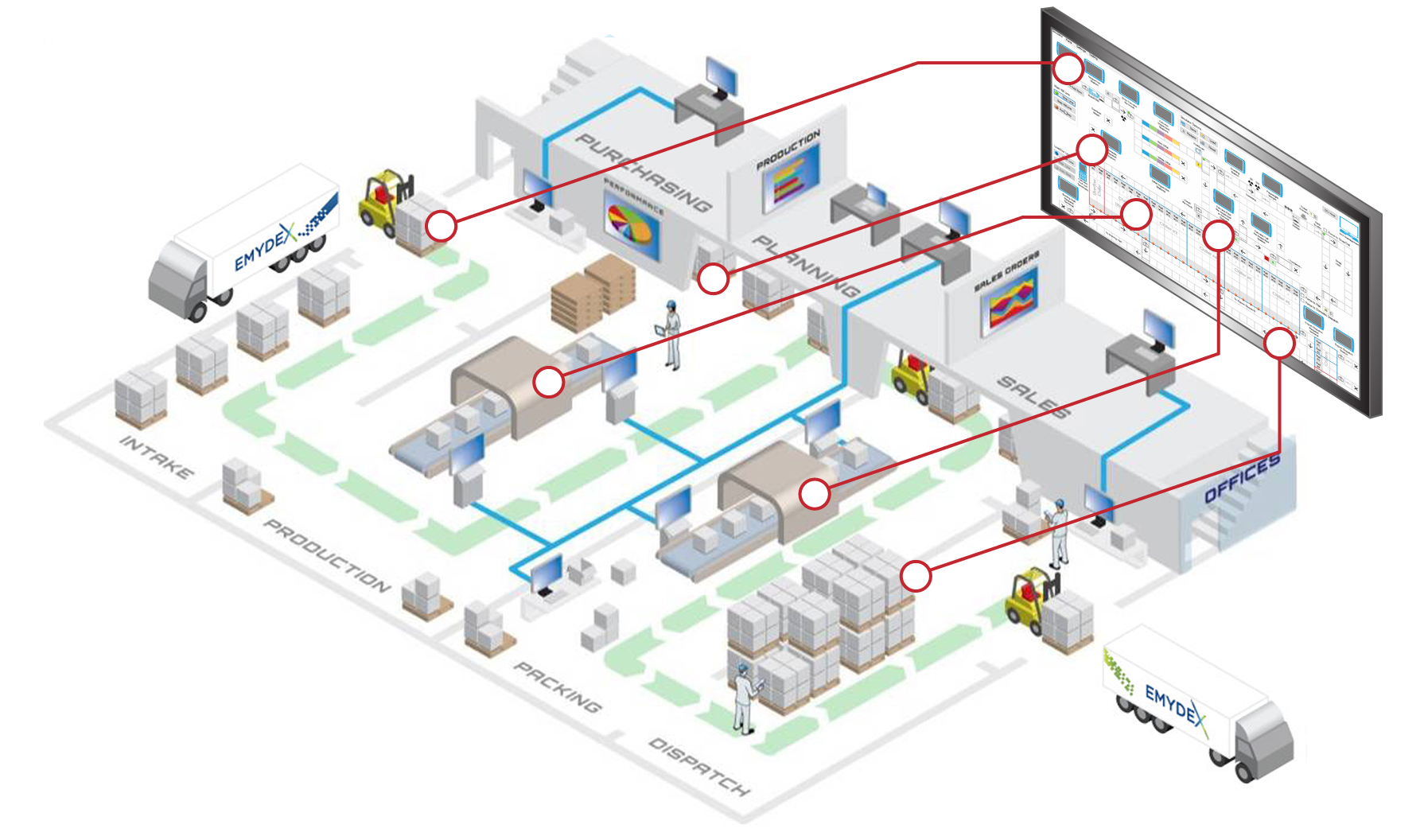

Emydex factory floor software for meat, fish, and food processing, integrated with Meat Messaging is one such solution.

Meat Messaging was developed by the Australian meat industry including organisations such as AUS-MEAT, DAWE, AMPC, AMIC and MLA to increase the market access to the US for Australian meat exporters and to reduce the number of rejects caused by missing or incorrect port marking of cartons costing the industry an estimated AUD14.5 million per year.

What is Meat Messaging?

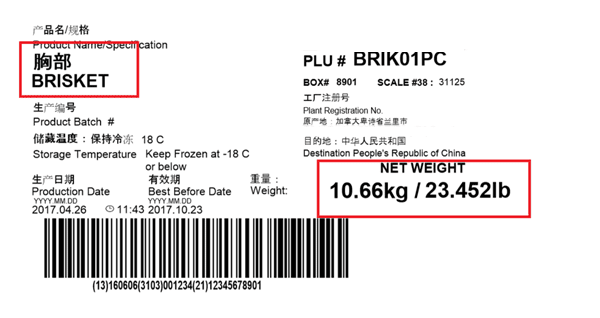

The system provides an electronic method to send a comprehensive list of GS1 labelled carton records, forming part of an export shipment including export certifications to a centralised cloud storage and indexing system and making that information available at the point of import.

Importers are presented with all the relevant traceability information through Meat Messaging to correctly identify cartons on a shipment and are now able to re-mark the cartons if any port mark non-conformances are identified. This process virtually eliminates the rejection of cartons due to port mark errors or omissions.

Key Requirements

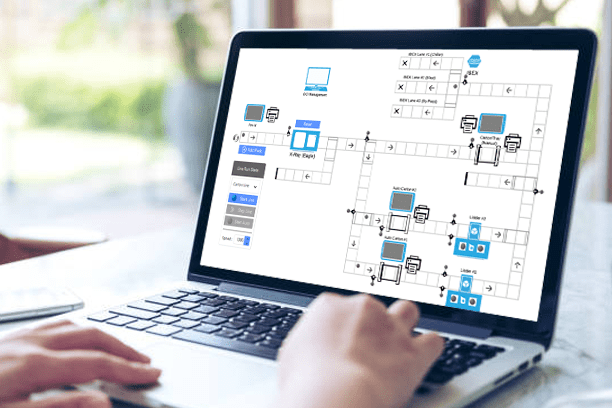

Two key requirements need to be fulfilled to integrate with the Meat Messaging system. These are the creation of GS1 barcoded cartons and records, and also to have the ability to send the shipment details and carton records to the Meat Messaging platform.

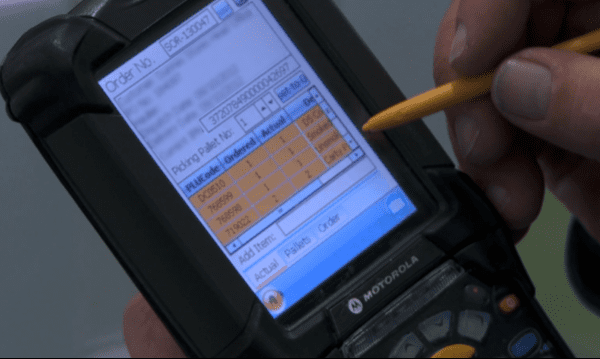

By making use of the Emydex Packing and Labelling solution which allows for the creation of the GS1 labelled carton records and the Emydex Sales Order Dispatch functionality in conjunction with the Emydex Meat Messaging web service, both requirements are covered.

Emydex has worked closely with the AMPC and industry producers to fully integrate the Meat Messaging system into the Emydex Factory Floor software modules to provide an easy to use and efficient interface.

This ensures that our customers can capitalize on the latest technological developments in the market and ensure that their products have the best chance of reaching their destination, gaining full value from each export to the US.

If you want to learn more – contact Ireland, Australia, South Africa or North America offices