Emydex Australia today announces the move to larger corporate offices in The Precinct in Central Brisbane. Located at 14 Browning Street, the new Emydex Australia Head-office is only a 5 min walk to South Brisbane train station, as well as Brisbane river walk that runs through Brisbane city.

The move coincides with a ramp up of the Emydex Australia team, with recent hiring of three new local software engineers, two of whom will join the Emydex Australia Solutions Implementation team, as well as one joining the local technical support team. This brings the total Emydex Australia headcount to eight, including local employees as well as a number of Emydex Ireland employees on secondment to Australia.

The Emydex Australia dedicated support team, works in tandem with the Emydex Ireland support team to provide 24x7 support coverage to Emydex customers located in 14 countries around the world. Recruitment is ongoing presently in Toronto, Canada, to add further support technicians to the global support team based there, for seamless 24x7 coverage for Emydex customers by way of 3 x 8 hour support shifts.

(Some of the Emydex Australia Team with David and James visiting from Ireland.)

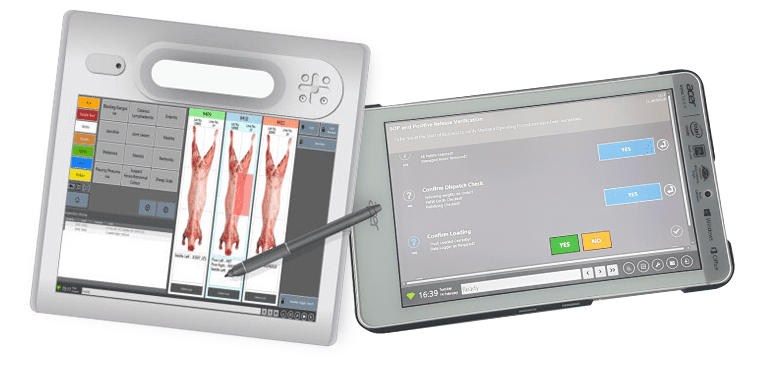

Emydex signed its first Australian customer, Junee Lamb in New South Wales, in early 2015. Despite locating its head-office in Brisbane since then, Emydex Australia only recently added their first Queensland processing customer to the customer mix in September 2018, signing contracts with the Sunpork Group. Sunpork Group are the largest Australian owned pig producer and processor, with head-office operations located in Murarrie, Brisbane. Emydex are contracted to supply a factory floor data-capture, production control and traceability reporting MES system to service a new state-of-the-art Kill Floor and Boning room operations at the Swickers processing plant located in Kingaroy, three hours outside Brisbane.

Our most recent go live was Harvey Beef, based in Western Australia. Part of Harvest Road Group and privately owned by the Minderoo Group, Harvey Beef is Western Australia’s leading beef processor. In December 2017, Emydex were invited to submit a proposal to supply and implement a software system which would improve their ability to address their current issues and support growth plans. After the publication and evaluation of an RFP, and a competitive tender process, Emydex was selected to provide the full end to end factory floor processing system, in tandem with Empired being selected to implement Nav 2018, as their choice of back-office ERP system to cater for Harvest Road’s core financials and non-meat inventories.

Other Emydex customers in Australia include Wodonga Abattoir in Wodonga, O’Connor Beef in Packenham, as well as Victoria Valley Meat Exporters all based in Victoria.

Commenting on the recent expansion of its operations in Australasia, David McMahon, Emydex technology CEO based in Dublin, Ireland said “Australasia is one of three key export markets we are focussed on right now in addition to Africa and North America. Brisbane appears to have a ready supply of software engineers and technicians, compared with Ireland where they are in scarce supply. To the end, the plan is for the Emydex Australia team to grow in size, not just to cater for our customers based in this region, but also to support our global customers, as well as to participate in a number of New Product development projects we are planning to deliver over the next 18 months.

These include Group Production planning and Animal payment systems geared at larger multi-site group processors”. He added “Our vision is to become the No.1 partner of choice for Traceability, Quality and Production control systems with leading meat, fish and food processors in our four key global markets. To achieve this means a need to maintain sharp focus on our core product and service offerings, customers and markets, working with local partners in each region for both Industrial hardware and back-office ERP systems integration”

For more information on Emydex Australia, please contact Ian Carson at ian.carson@emydex.com.au