Following acquisition and growth, The Canadian Fishing Company (Canfisco) found themselves with a variety of different legacy IT systems, all working independently. They turned to Emydex to help land one system that integrated everything.

Meet the client

The Canadian Fishing Company (Canfisco) has sustainably harvested wild fish from the coastal waters of the Pacific Northwest for over 110 years. The company operates the largest fishing fleet in British Columbia, over 850 vessels, that every year lands over 100 million pounds of mostly salmon, herring, rockfish, halibut and hake. Landed fish is supplied to the company’s nine processing plants located on the pacific coast in Richmond, Prince Rupert, Greater Vancouver, and Alaska.

The opportunity

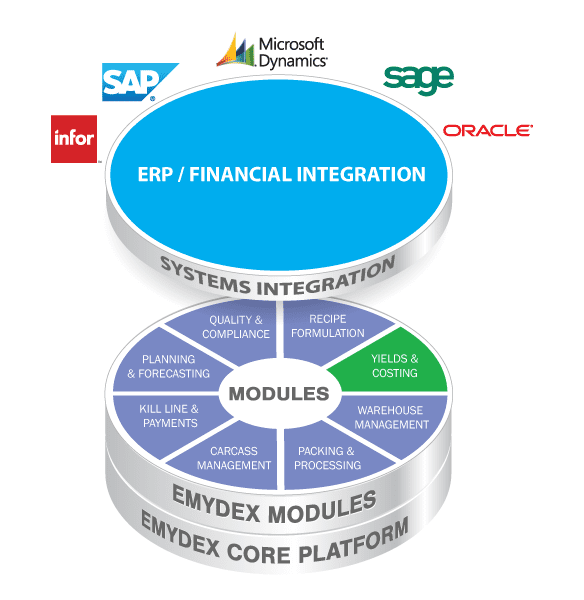

Canfisco has grown both organically and through acquisition. As each new acquisition was moved into the Delta Pacific Seafood location, the software and processes were not consolidated into a single integrated process or software application. This left Canfisco with six different major applications and many Excel applications to compensate for the different systems at work throughout the group.

“Company acquisitions had left us with a patchwork quilt of components and old systems that were handling all of our processing.”

John Capling, Project Manager, Canfisco

However, the greatest risk to the business came from the out-of-date applications running on an over 25-year old Unix platform with limited hardware support. This environment left a very disjointed operation that only worked due to the efforts of staff acting as the glue to keep everything working together. Before Emydex came on board, Canfisco had at least five BOM process, four box labelling process and three separate financial applications in place in the organization.

What we did

Canfisco needed a new IT system that could provide a single source of the truth for the organization, providing improved visibility and measurement throughout the business, streamlining administration and, ultimately, improving the performance of the company.

The consensus within the various departments and plants was that any new software solution should be able to replicate what they were already doing, process-wise, i.e. it should keep the good things that worked well and with which everyone was familiar. To this, we should add some magic in the form of some low-hanging savings improvements, whilst at the same time providing the foundation for a software system that can grow into a more advanced solution over time.

Although we are replicating Canfisco functionality I was impressed to see how the Emydex team automated the link between the plant’s recorded catch of fish to actual sales, to ensure Canfisco sales can presell the fresh fish. This ensures they can get maximum value for the catch versus having to freeze the fish for less profits.

Terry McCorriston, Sales Manager/Business Analyst, Emydex North America

Going Live

Canfisco understood that they needed to address the highest risk area which was the groundfish applications running on the old Unix system so a phased implementation was taken to minimise any operation interruptions. After initial consulting and analysis, it was decided to go live with the ground fish box labelling and fillet line in December 2019 and bring on the port receiving in spring of 2020.

The Results

Key to the success of this project was to ensure it would be a gentle evolution and not a revolution. Keeping staff at all levels throughout the operation happy was very important and Emydex was careful to tread lightly. The most obvious improvement has been the elimination of the major risk of running the business on antiquated unsupported Data General (DG) Unix equipment. While there are a few minor applications still on the Unix platform, the team is working to quickly migrate them in the next phase.

Phase one has been completed but already administration efficiency has improved, as expected, thanks to reduced duplication of entry into multi applications and processes. Time consuming consolidation has been reduced and as other fish species are migrated to the new system in upcoming phases, staff will see all of the improvements fall into place.

“Emydex combined a bunch of old systems into one to handle all of our processing. Now everything is processed and tracked through one piece of software. Phase one went very well and so far, it is looking very good and the great thing is there wasn’t a steep learning curve for our people on the floor. Visibility has improved greatly, and we know real efficiencies are coming down the line.

Emydex took what we liked from the old systems and mirrored it, especially with scales and processes – things are labelled now and tracked automatically as opposed to manual entry of old.”

John Capling, Project Manager, Canfisco

There is now better traceability of fish from catch, through processing, to the end sale. Operational performance has improved too due to reporting on giveaway and production yields (with a potential of 2% improvement in raw material utilization) and, of course, Emydex has provided the foundation to build the operational performance measurements over time.

Interestingly, most of the implementation was done remotely which saved costs for the client and also worked out perfectly as the Covid-19 pandemic struck right in the middle of the project and had little effect on our timelines.

“I was happiest with the Emydex team’s flexibility to work with Canfisco to adapt (the software) to allow a phased implementation. I was also impressed that Emydex was able to handle the volume of transactions from day one of going live.”

John Capling, Project Manager, Canfisco

What's Next?

This is the first phase of the implementation – the next phases will cover other fish species – and it builds the foundation applications for future improvements, including analysis of expected costs against actual costs, gross margin visibility at the different levels (including vessel, customer and sales order analysis). Improvements in dry goods control will come next as will the automation of HACCP and QC processes and cold storage invoicing.

In other's words

“Emydex spoke our language, much more than Microsoft… they understood our industry and our business. The (Emydex) system is friendlier, easier to use, intuitive and when the warehouse guys saw it they gave us their blessing so the decision to run with it was a no-brainer in the end. It has replaced very old legacy systems that weren’t integrated and left us very exposed to risk. The result is a solution that’s much more efficient and customisable so that we can add functionality as people have requested it.

The Emydex team were great – very responsive and easy to work with, despite the time difference… very professional and they really know their business. I’m looking forward to Emydex expanding further into our other processes, cold storage, our warehouses and beyond”

Mark Cornell, Senior Vice President

Contact Sales in any of our Dublin, Brisbane, South Africa or Toronto offices