Emydex CEO Update – 2022 Review

Looking back on 2022, last year continued with the trend of challenging global trade conditions with the War in Ukraine fuelling a global energy crisis and rapidly rising inflation. Not much of a break in the weather post the Pandemic that overshadowed most of 2020 and 2021.

Despite these challenges, Emydex continued to grow and expand in 2022 with double-digit revenue growth over 2021. The company continued to grow in our key overseas markets, with a team of over fifteen full-time employees now employed across our two subsidiary companies in Australia and New Zealand.

Project work continues at pace with our New Zealand customers, Silver Fern Farms, Wilson Hellaby, as well our newest customer in NZ, Open Ocean, an indigenous mussel processing factory in Opotiki, North Island.

Our Emydex team in Australia was boosted by the arrival of some highly experienced Emydex employees including Jeffrey Macer Wright (Emydex South Africa) as well as Carl Brennan (Emydex Ireland) who both permanently relocated with their families to Australia, to work out of our Emydex office, located in South Brisbane.

Jeffrey and the Emydex Australian team are busy working on system expansions and upgrades with several customers in Australia including Harvey Beef, Junee Lamb, as well as new customers Mort & Co and WAMMCO.

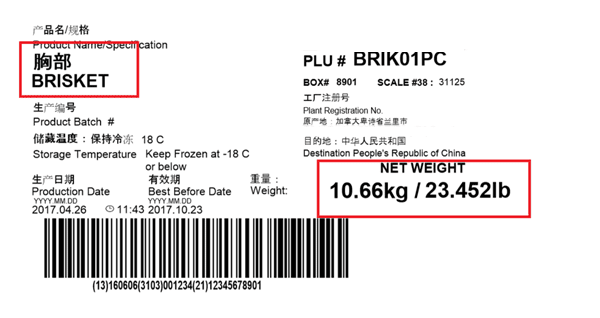

New product developments completed by Emydex Australia include a new Meat Messaging system, developed in conjunction with the Australian Meat Processor Corporation (AMPC). This new system enables Emydex customers to electronically send a list of GS1 labeled carton records (for export shipments, including export certifications) to a centralised cloud storage system, which virtually eliminates the potential for rejection of cartons due to port mark errors or omissions.

The Emydex team in North America has also grown on foot of some significant new customer wins, including a large multi-plant poultry processor with over ten primal and further processing plants spread across Canada.

Back home in Ireland, the Irish team are also busy on several large customer upgrades to our latest Version 6 software, as well as New Product Developments including:

Android Scanning (XDA)

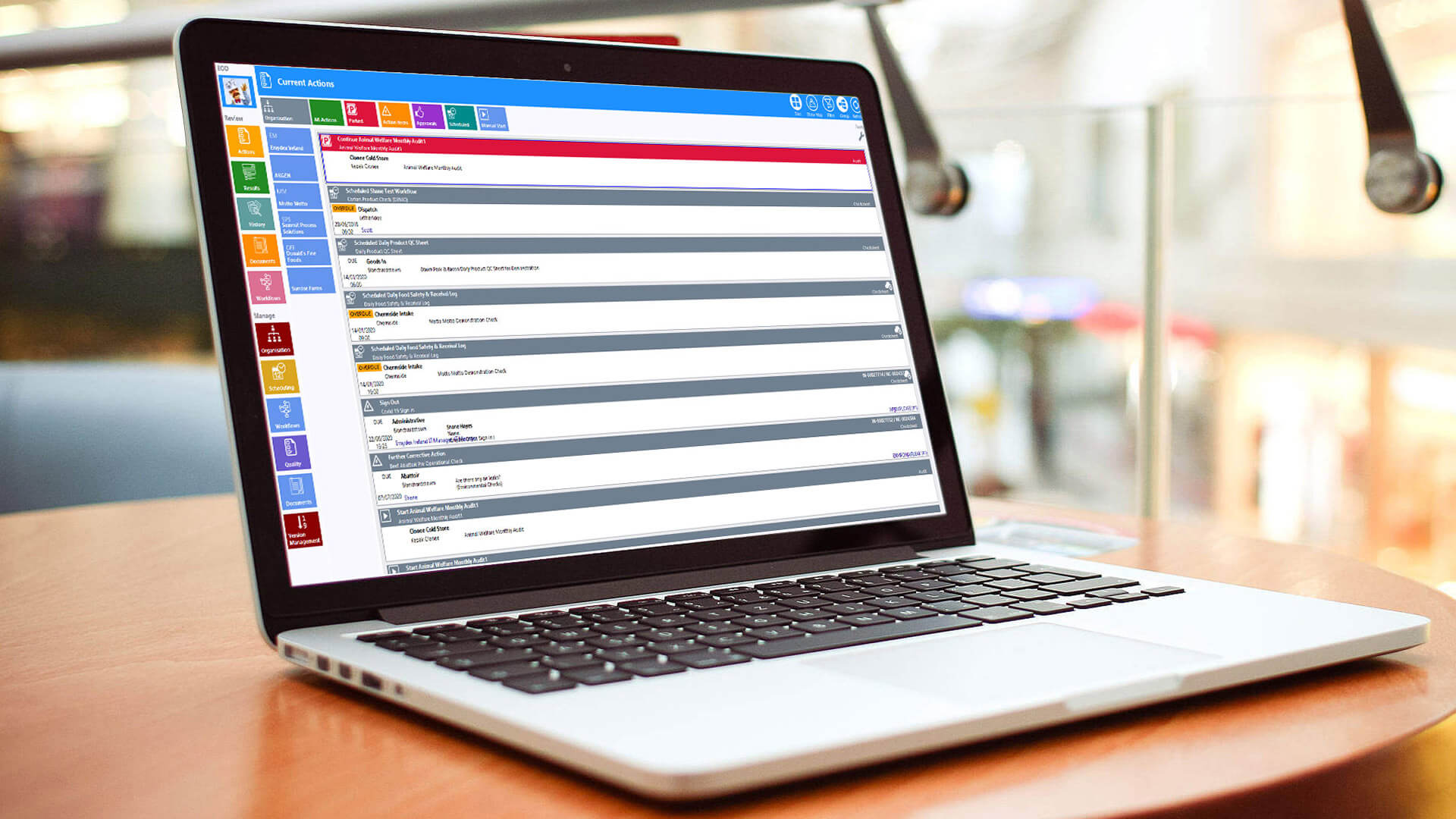

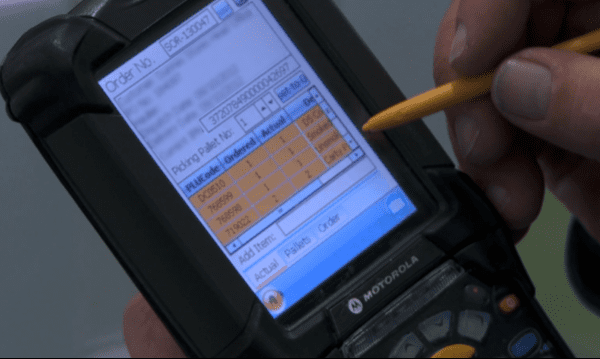

A new Android-based Emydex application running on handheld scanners used for Warehousing functions including Stock management, Issue to production, QC Hold, Containerising, Palletising, Sales Order picking and Dispatch. Feedback from early adopter customers includes “I have been so impressed with the new Emydex XDA. The speed at which it works is fantastic even with the database being in the cloud” Operating on Android devices means Emydex customers can source devices, from a wide range of manufacturers, at a lower cost compared to previous Windows mobile devices.

Central Animal Payments (CAPS)

A complete rewrite of our widely used Animal kill line payment system. CAPS provides the core ‘engine’ which is used to not only generate payments to livestock suppliers but also to those other entities involved in supplying livestock such as buyers, agents, and transport companies. In addition to generating payments, the system can produce accounts receivable invoices for service processing allowing suppliers to be paid.

Supplier Relationship Management (SRM) Portal

A new web-based application that enables Emydex customers to manage their supplier audits over the web. Suppliers securely log into an Emydex web portal to complete self-assessment questionnaires/assessments (SAQ), collect relevant documents, submit product specifications, and manage contacts. The supply chain manager will be able to manage everything related to suppliers completing SAQs and managing their supplier’s approval status & risk rating. As well as this, they will be able to receive notifications a view all information submitted by the supplier.

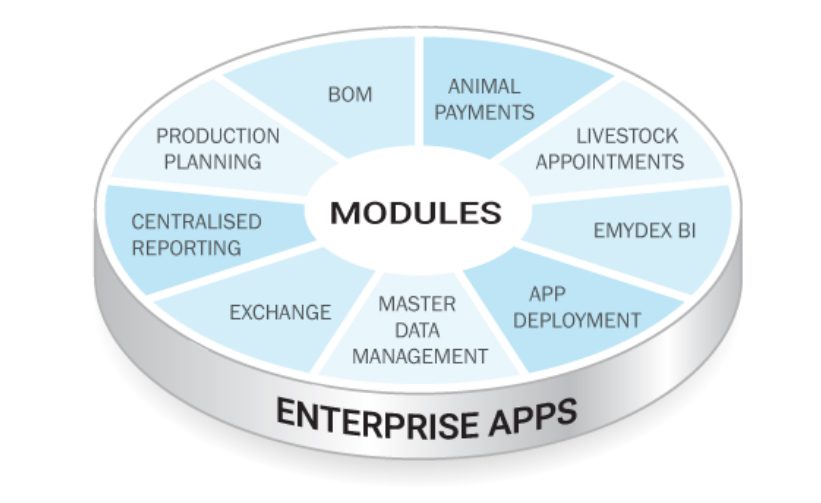

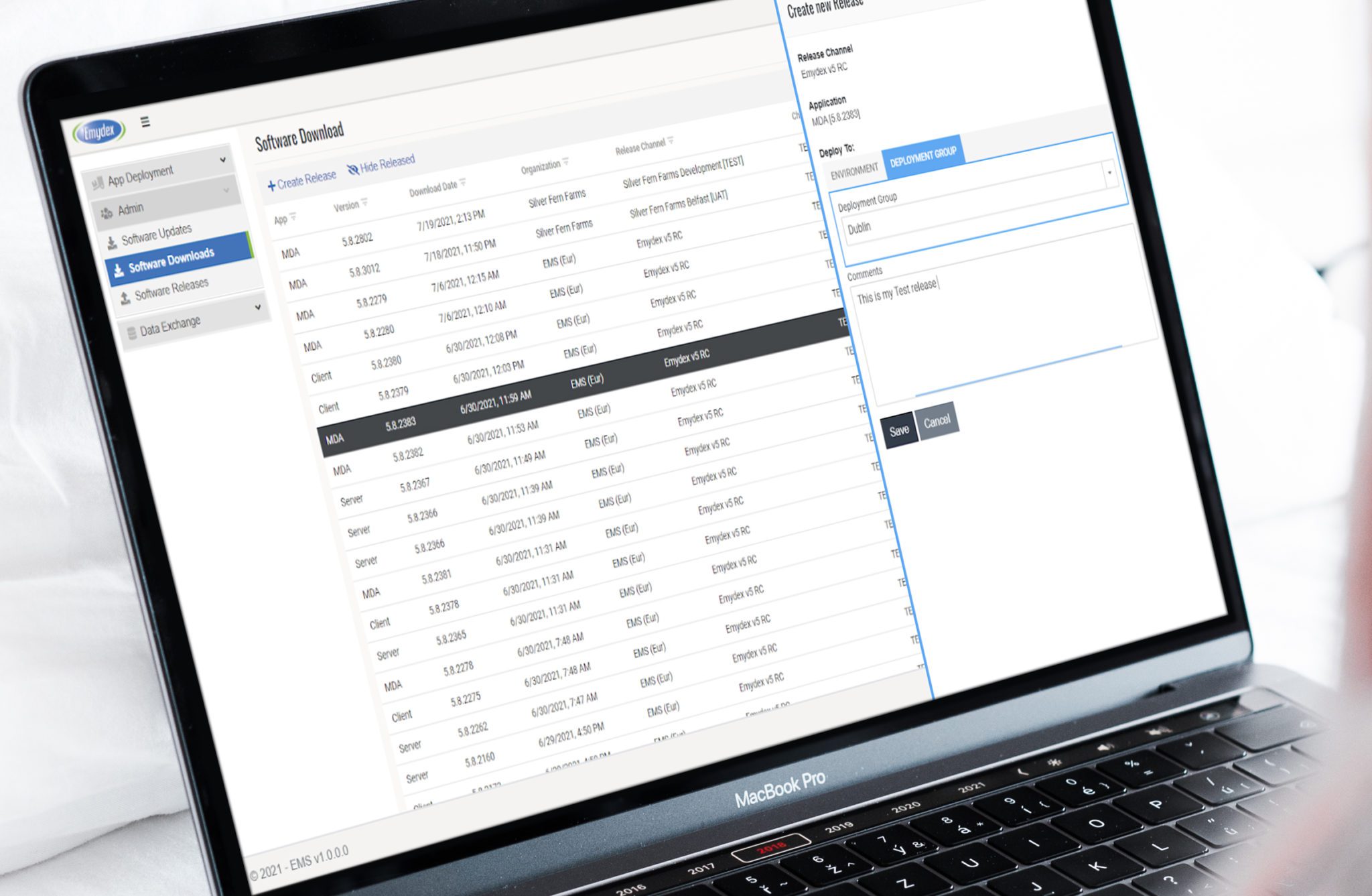

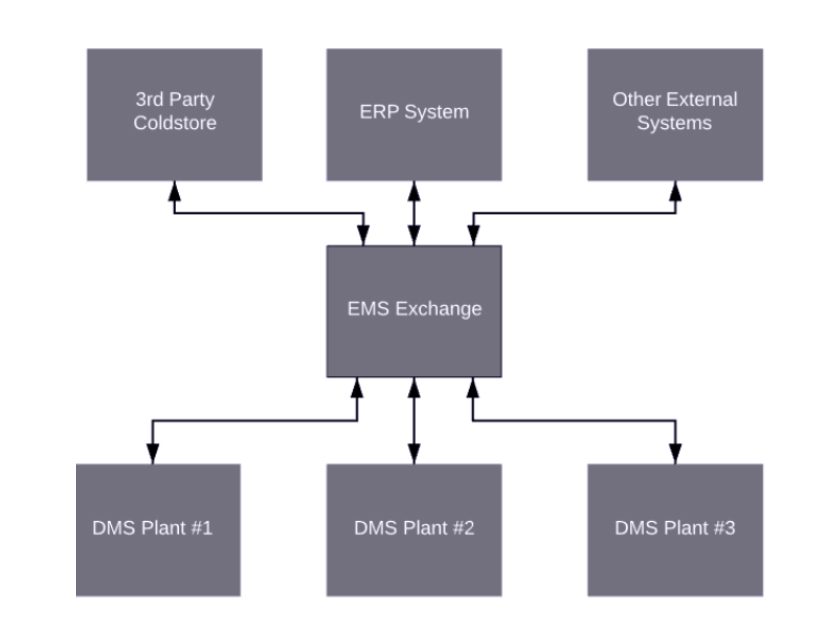

Other new products in the Pipeline for 2023 include further development of our new Enterprise Management System (EMS), a corporate-level suite of software applications targeted specifically at maintaining data integrity, reducing data entry, and improving control across multi-plant businesses.

If you want to learn more – contact Ireland, Australia, New Zealand, South Africa, or North America offices