NORTH AMERICA:

The food industry is no different than any other complex manufacturing business whose goal is to make a profit. If you are not able to calculate your true manufacturing cost, it could lead to lost profits, orders and customers. To remain profitable, you need to answer a number of questions; Are you pricing your products to make a profit? Are you producing the products at the cost you calculated? Are you contributing to overhead and profit levels to meet your strategic business goals?

In the food industry, there are very small margins, making it difficult for food companies to achieve and maintain profitability. One of the first lessons of accounting is the equation of Profit = Revenues – Costs

In the food industry, the volumes are fairly flat, growth is slow, so food processing companies need to be focused on managing costs as the best option to improve profitability. Determining what are the product and customer costs is not as simple as it seems in the food industry. Over the last 15 years many food companies have either gone out of business or been bought out by a larger company due to lack of profit.

Current state of ERP vendors able to support the food industry costing

Food companies are not able to calculate accurate costs with their current software systems due to limitations in these systems required to support food industry requirements. The quality and specification of raw materials vary significantly from vendor to vendor and at different times of the year. This is especially true in the meat industry where each species carcass is a different size and weight, so for example, each ham or loin produced has different amounts of lean/fat, bone and trim.

The process of blending, mixing and cooking can produce different yield losses depending on the attributes of the raw materials used, and the setup of the equipment. ERP vendor software is not designed to track and measure yield loss tracking as the product moves through the various food production processes.

Due to the limitations in the costing functionality, many companies use manual (spreadsheet) calculations to determine product costs. While spreadsheets may work for smaller, ad-hoc analysis, they fall short in handling massive complex costing processes due to their limitations with scalability, data integrity, integration and security. They are also open to clerical error (no validation), and are typically reliant on a few key individuals within the organisation. The ‘hit by a bus’ risk is a cause for concern.

Furthermore, manual cost calculations are then fed into some type of profitability analysis, but the challenge is that the manual data capture is flawed, making these analyses less than optimal. For food companies to survive in the current economy they require accurate and complete profitability information.

Addressing the challenge of calculating costs

From the big picture perspective, it is relatively easy to calculate profit. Total up all your revenue and expense accounts and calculate the difference between the two. This tells you that in total income made or lost, but at a macro level. The calculation of profit for specific products or customers can easily explode into a massive undertaking. Companies do not know where to look to address their profitability issues.

The current situation of limitations of profitable reporting is a direct correlation with the challenges the food manufacturers face when calculating accurate cost results – lack of an automated costing process, substantial manual processes, lack of operational measurement to ensure accuracy of results and lack of granularity.

Food companies have tried different approaches to address the costing requirement. They have tried sophisticated spreadsheets, in some cases using a network of complex spreadsheets. Others have attempted to modify their ERP or Financial (GL) systems to handle the advance costing needs of the food industry, but often these modifications fail to deliver a comprehensive cost system. Lastly, companies have embarked on building their own custom cost system from the ground up. While these systems will give the company exactly the costing system they want, it comes at a significant cost of time, money and resources.

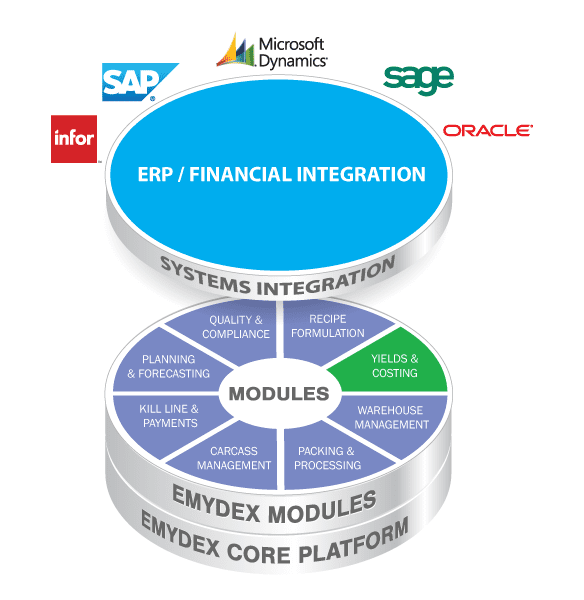

Operational costing systems are the next generation of solutions created specifically to handle the complex costing and measurement environments encountered by food process manufactures. These package solutions that integrate with your existing ERP or Financial System allow companies to rapidly gain access to detailed cost data that that is specific to their food production process. Access to detailed product information brings a whole new level of insight on operation performance and arms the Operational Management team with information to effectively manage and implement continuous improvement projects to reduce costs.

By adding an operational costing and measurement system to the existing business systems, food manufactures can remedy many of the symptoms that produce an ailing cost process.

How Operational Costing in the Food Industry Improves Profitability

Your competitor just undercut your price, so to be competitive in the market you’re probably thinking that all you have to do is meet or beat your competitor’s price to get the deal. Let’s just reduce or eliminate the overhead contribution, and quote the price based on the materials and labour, then mark up the cost to meet the company profit margins. Right? Wrong. There are many manufacturing companies who price on the basis of what their competitors charge or the market price, without considering whether their competitors have a different cost structure or knowing their own true manufacturing costs. If you base your prices on what others are doing, you’ll never know if you’re taking in profitable business.

Instead, adopt a different approach that will bring in profitable business while remaining competitive, by implementing Emydex’s Yield and Costing Module that is a fully integrated component of the Emydex Production Management Platform, that is tightly integrated to your existing ERP or Financial System.

Yields & Costings Module, on Emydex Core Platform, integrated to back-office ERP

With the recipe BOM (Bill of Materials), Emydex is able to model the flow of raw materials, ingredients, packaging, resources and overhead through the food production process. By monitoring actual costs and product movement through the process, Emydex is able to generate yield variances, and measure the financial impact of production using standard reports to validate the accuracy of the costing standards.

These costs and variances can be integrated with your existing financial system to provide a more global analysis of profitability.

By knowing the true costs of producing products at your food plant, Emydex’s Yield & Costings software gives you the knowledge needed to make strategic and operational decisions that will keep your business profitable.

Terry McCorriston, Authorised Distributor, Emydex North America

Emydex Canada / North America

Emydex Canada / North America

Terry McCorriston Consulting

28 McGibbon Crt

Kitchener, Ontario

Canada

N2A 3P2

T: + 001 519 500 0540