Emydex have been a long time user of bar coding technology as a means of maintaining traceability throughout their applications. Whilst we have been aware of, and trialled RFID technology for the past few years, it is only in the last 12 months that Emydex have really started to utilise RFID technology in real-life operational environments, enabling our customers to gain from the benefits of its application.

There are essentially two types of RFID tags, passive and active.

Passive Tags

Passive tags are generally lower cost and have a longer life cycle. They are encoded at manufacture with a unique ID number. This ID number can only be read from the tag when it is inserted into a radio frequency field generated by an RF reader. The efficiency of the reading is dependent upon the strength of the field and the time that the tag is in the field. This generally means that the tag has to be as close to the reader as possible at the time of reading.

Active Tags

Active tags have their own power source in the form of a battery. They are therefore more expensive and have a finite lifetime (battery life). For this reason active tags are best utilised in closed loop systems where the tags never leave the premises. Like the passive tags they are encoded with a unique ID number at the time of manufacture. In addition an active tag can be manufactured with varying amounts of read/write memory, enabling applications to write variable data to the tag for later retrieval direct at a reading point.

By means of the internal battery the tag can broadcast its data at the same time as the tag readers are creating the reading field. This leads to a greater tolerance on reading distance.

Advantages

The greatest advantage of RFID tags over bar coded tags is that the tag can pass through the reading field in any orientation; this makes total automation, without the necessity for operator interaction a viable proposition.

Emydex have used both types of tags dependent upon the application. In the case of carcasses being transported on an overhead conveyor there is no need for active tags. The tags are encapsulated in a heat and impact resistant plug which is embedded in the carcass hooks. As the hooks are on a track system the readers can be positioned very close to the hooks. The tagged hooks recirculate within the system and never leave the site. By positioning data capture equipment close to the reading locations Emydex are able to 100% verify correct carcass data with no possibility of sequencing errors.

Examples of data that can be captured and recorded in the system relative to the hook tag ID are:

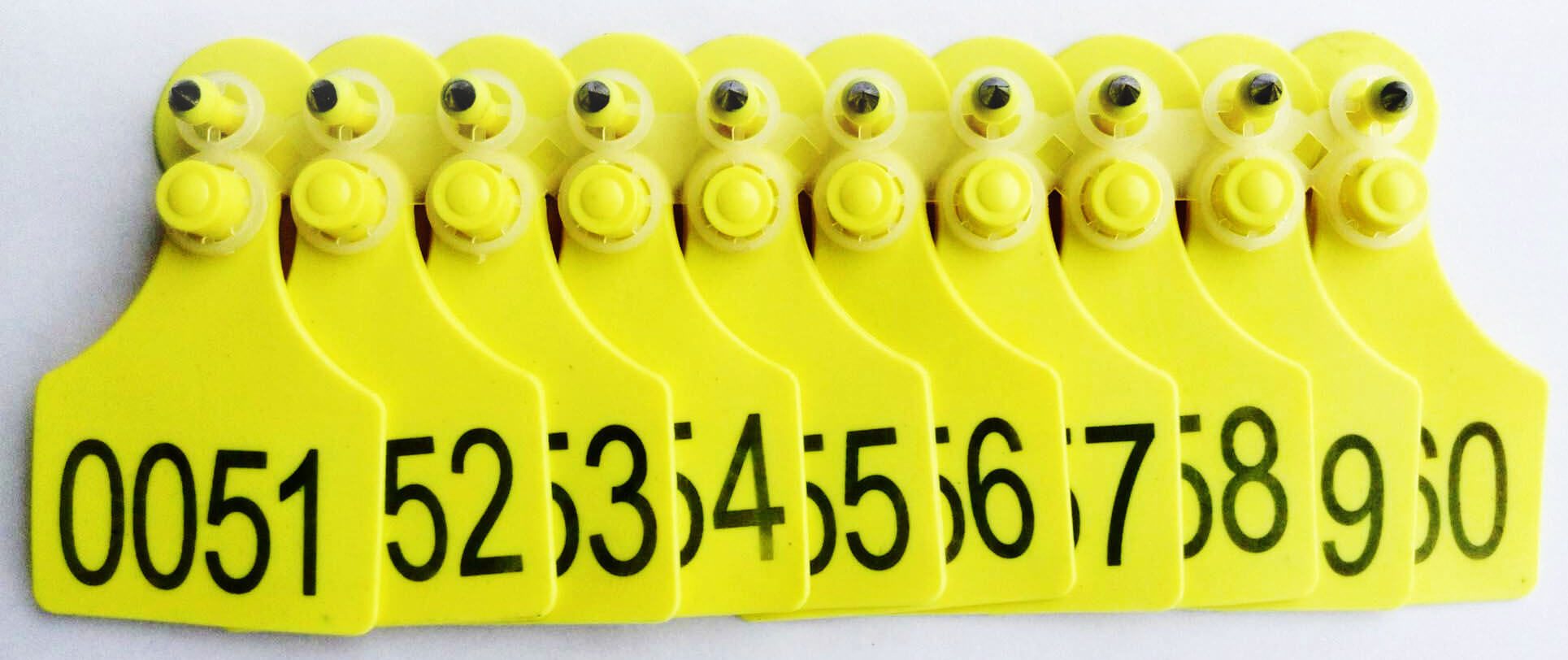

- Ear Tag

- Dentition Data

- Tissue Samples

- Veterinarian Data

- Carcass Inspection Data

- Classification Data

- Weight Data

- Chill Location

After the classification, bar-coded carcass tag labels are printed enabling forward traceability reporting of the carcass, after it has been removed from the original carcass hook.

By situating readers at strategic points on the track it is possible to identify exactly where each carcass (and carcasses in a lot) is located in the abattoir.

Another application for which we are using RFID is the destination control and product/operator traceability of plastic crates (and products within) in a processing department.

Each crate in the system is embedded with an active RFID tag. This tag has a unique ID number and an amount of memory for reading and writing data.

Operators place their output products into the crates. Via strategically placed read/writers and data capture equipment, the contents of the crates can be identified against individual operators and individual processes. The required destination of the crates can be written to the tag, enabling subsequent tag readers to automatically direct the crate through the conveyor control system until it reaches its next process or packing machine destination.

The Benefits

The benefits of automating such processes are a smoother product flow, greater operator efficiency (enabling better throughput and yield), less drip loss due to shorter overall processing times, better traceability. Not only can the system 100% trace the contents of every crate but it can also identify every product that has ever been in that crate, and everywhere that crate has ever been.

This experience has resulted in Emydex investigating alternative applications for RFID, particularly regarding the speed benefits of being able to read multiple tags at the same time and the efficiency benefits of effective automation.

Our initial investigations suggest that every company can benefit from using RFID in closed loop systems (where the tagged containers stay on the site or stay within the group), whether connected with fully automated solutions or not; the readability of RFID tags without the necessity of line of sight (as with bar codes) can have a significant impact on efficiency.