Tracking Operational Performance in Food Processing is significantly different than in traditional Manufacturing Processing.

I worked for many years as a Director of Technology for a large multi-site meat processor in Canada. I later switched tracks to become an independent software consultant helping several mid to large meat processors. For the last 15 years, I have worked with software vendors like Emydex, to implement shop floor solutions for meat, fish, and food processors. I have been trained in the standard APICS (American Production and Inventory Control Society). The APICS standard approaches for manufacturing control needs to be modified to support the requirements in the meat and food processing industries.

Users and companies in the food industry are very hands-on people looking to provide the best quality food for their customers, with many of them skeptical about the use of software to improve their processes. Their work experiences have found that standard ERP shop floor software does not work for their operations and these companies are having to rely on many manual workarounds with limited improvements. The key phrase used in a continuous improvement project is “What gets measured, gets managed” and what’s managed, improves! The problem is getting reliable production information from the shop floor in a timely manner.

The key to providing accurate operational measurement and traceability is tracking the movement of materials from initial receiving through the production process to a final finished product and shipment to the end customer. The diagram below shows the required flow for production control.

Receiving / Intake Purchase Orders (PO)

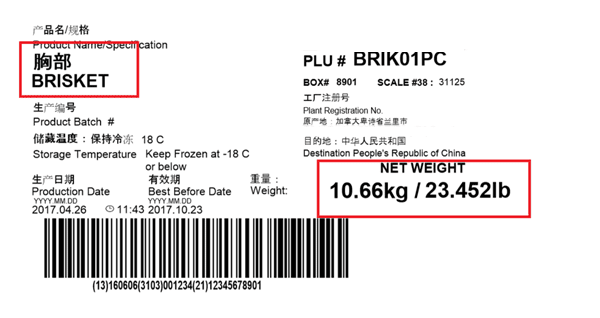

Like other manufacturing, all goods for manufacturing need to be received against a purchase order (PO), the difference is that during the intake/receiving process there are several additional information points that need to be captured.

In addition, the received materials require a readable barcode from the supplier or have one created the intake/receiving process:

-

- Food Processors require traceability of all the raw materials, ingredients and any packaging materials that make contact with the finished product

- For raw meat and vegetable materials, we need to capture what vendor/packer harvested the animals and on what date were they harvested.

- For ingredients and packaging, we need to capture Lot information and best before dates

- We need to capture both quantity (number of containers) and weight or volume of the received materials. The software needs to be capable of tracking two units of measure, quantity and weight or volume in inventory. We need to keep track of Lot and other information in the inventory control module.

- It is hoped that the vendor providing the purchased goods would provide readable barcodes of the received product, but frequently the receiving plant will need the capability of creating internal barcodes to apply to the receiving pallet or in some situations, each individual container

- In the food industry there are many HACCP and Quality checks that are required during receiving to ensure the purchased material is safe for use in production

The receiving process provides the initial traceability link to the received materials

Once the material is received it is moved to an authorized inventory storage location. In the food industry companies need to control where allergen materials are stored. This receiving/intake process is critical to assign an internal lot number to allow tracking through the process and back for recall and measurement reporting.

Production Work Orders (WO)

The next key process is to track to issuing materials to a production Work Order in order to transform those materials into WIP (work in process) or finished goods. Many food processing companies struggle with the concept of work orders. A work order is a document given to the manufacturing shop floor by the production planner as an authorization to manufacture a certain quantity of one or many items. The work order provides all the information about a production task. The work order can include details on how to complete the job, the location or area that the job is being completed, what ingredients and materials are required and the expected output from the completion of the work order. The work order is also the link (traceability) of the flow of product through the food plant.

All food plants have some method of informing production what they should be making, many plants do not call these instructions a work order but that is what is used in best of class food processors. The work order is the method of allocating ingredients/materials and labour transactions to a production step or task. The value of using a work order is that they tend to boost productivity in very efficient ways because of the clear instructions and it provides the data capture points for continuous improvement monitoring.

Most food processors start with creation of the work orders manually based on a production plan, and then over time look to leverage the capability of their ERP system MRP module to generate the production demands in the form of work orders.

The work order is the tool to convert or consume materials and convert them into producing a different enhanced output product either a finished good or a work in process item. The work order is able to generate operational measurement reports in the form of yields (measurement of input product compared to the output, and measurement of standards (BOM) quantities to actual quantities used or produced) and labour analysis. Since the plant solution is yielding data from purchasing through to the end production, the software solution can capture and flow actual costs from a PO to an end product.

The purchased material can flow through multi work orders of blending, forming, cooking and finally a packaging work order to produce the finished goods. The work orders provide the links through the production process to track the movement of product and capture the manufacturing performance of yield and labour.

Inventory Control

Inventory control is the module that monitors the plus and minus as the materials movement through the production process to finished goods and eventually to an end customer. The inventory control module in food processing requires the following unique functionality:

- Ability to manage and control two units of measure

- Quantity, boxes, pallets, containers, totes

- Weight or Volume

- Note the solution needs to be able to track variable weights (catch weights) as materials in a container can each have a different weight (example each box with 3 hams in a box weigh a different amount)

- Ability to capture lot information

- Serialized box and pallet control improve the accuracy of inventory

- Ability to control dates for the product

- Best before

- Use by date

- Harvest Date

- Etc

The inventory control module is used to ensure you have the correct amount of inventory to support production, Min/Max levels, and age of the products. The inventory module is also the control tool to ensure all the production process are flowing correctly. Inventory control can provide the following improvements in operations:

- Reduce distress sales and plants have visibility as products are reaching their sell by dates

- Reduce production material expediting as the availability and age of the materials/ingredients are verified prior to production

- Efficiency of finding the products is improved as the inventory control system is aware of where stock can be located at all times

- Inventory turns can be tracked to ensure efficient use of warehouse resources

- Ensure optimal stock rotation that ensures the oldest materials are used first

- Any missing production transactions will show in inventory

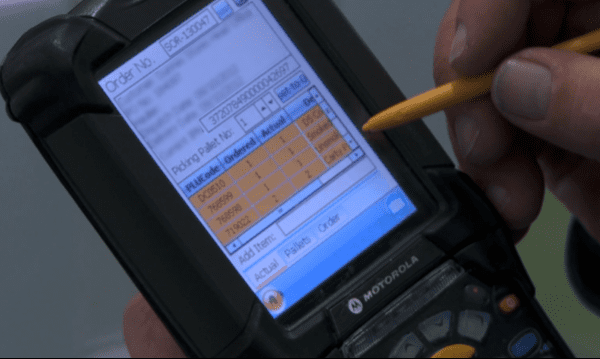

Sales Order (SO) Picking

Sales Order Picking is the final transaction of issuing products to customers and have the following unique requirements in food processing.

- Controlling of order picking to ensure the oldest or the oldest product that a customer will accept is picked. Note that some customers have specific age restrictions that they only will accept fresh product that is no greater than 3 days old or product must have a best before date of 30 days. The picking software needs to be able to support those customer specific requirements.

- During picking we need to capture the actual container variable weights (catch weights) as product is sold by the container but priced by the weight in the container

- The efficiency of the order pickers can be monitored

- All the lot traceability information needs to be captured during the picking stage

Conclusion

Implementing a formalized production process that is controlled with work orders saves a lot of time, it can increase efficiency, reduce overtime, improve visibility of production, and provide traceability for any recalls that could be required.

Food Processing continues to get more complex due supply chain pressures, labour shortage, the need for production efficiency in competitive markets and the looming price pressures.

Emydex Technology has a proven food industry solution that can integrate with your current systems.

Please contact me Terry McCorriston to start your journey to improve operational performance on the shop floor.

Contact Sales in any of our Dublin, Brisbane, South Africa or Toronto offices