A New Era In Food Enterprise Management Software Applications

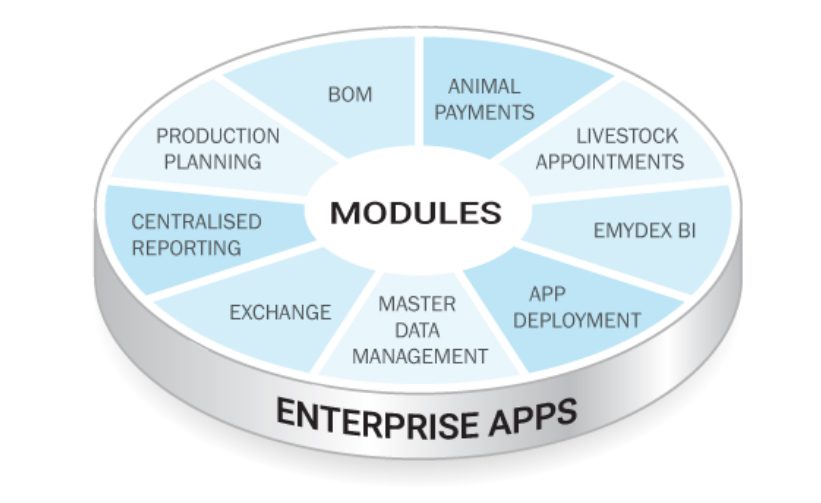

Emydex’s new suite of Enterprise Management Software (EMS) applications are designed specifically for multi-faceted food processing companies, those which are mainly multi-plant operations, usually overseen by a group HQ plant. Typically, these plants are spread geographically across a country or several countries and would be large food processing organisations.

It is difficult to maintain data integrity across these often-complex businesses, is often labour intensive and prone to human error with the duplication of information across multiple systems.

Emydex Enterprise Management System (EMS)

Emydex’s answer to this problem is the Emydex Enterprise Management System (EMS) suite of software which comprises a series of web apps targeted specifically at maintaining data integrity, reducing data entry, and improving control across plants.

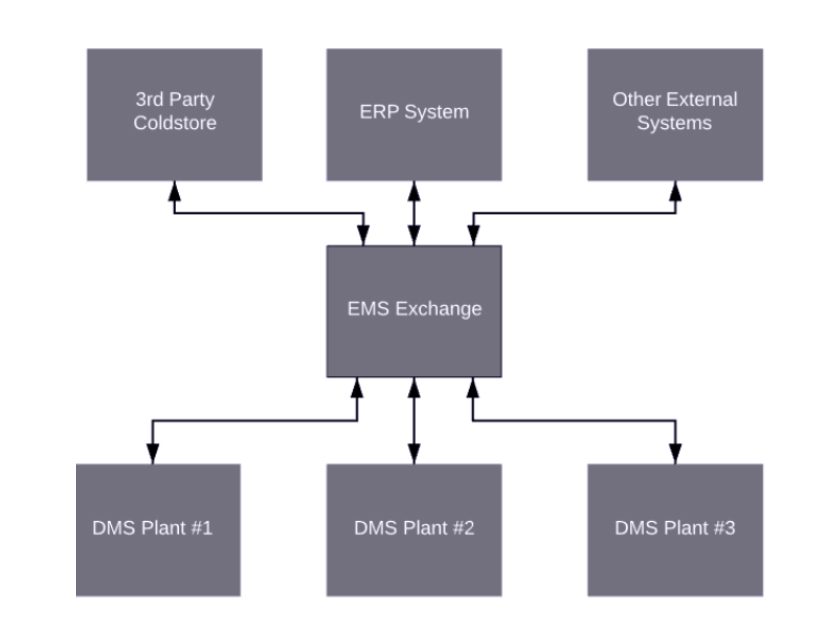

From a system architecture point of view, the EMS layer resides between the customer ERP system and the various operating plants.

The EMS layer of the Emydex software stack is made up of several web apps tailored toward solving these problems for multi-plant customers.

Business Intelligence (BI)

Emydex BI is the latest app of the Enterprise layer allowing customers to surface data to provide visual real-time and trending analytical dashboards. Sitting at the corporate level allows integration to multiple plants to surface data as well as other third-party systems such as ERP & financial systems. Find out more here

Master Data Management (MDM)

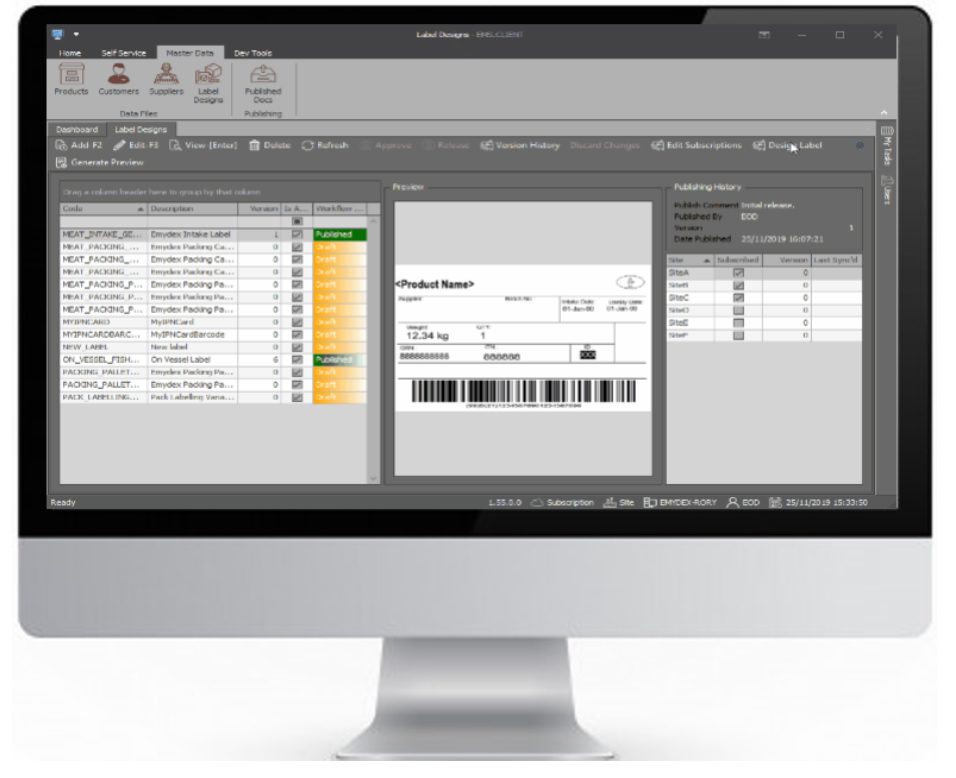

Master Data Management (MDM) is designed to control data integrity to ensure it is consistent across all plants. The Master data management module allows customers to centrally manage master data such as products, label designs, kill line destinations as well as other required data.

This removes the effort needed by plant staff to replicate data into each instance of Emydex which instantly reduces the risk of human error. With EMS MDM, corporate users can centrally control all aspects of master data which creates consistency across the business. An example of this is that if a label design is managed centrally, the label will look identical, no matter the plant it was produced from, which from a customer's point of view can be critical. This can also reduce incorrect labelling which can cause product recalls and market rejections, impacting the business brand and reputation.

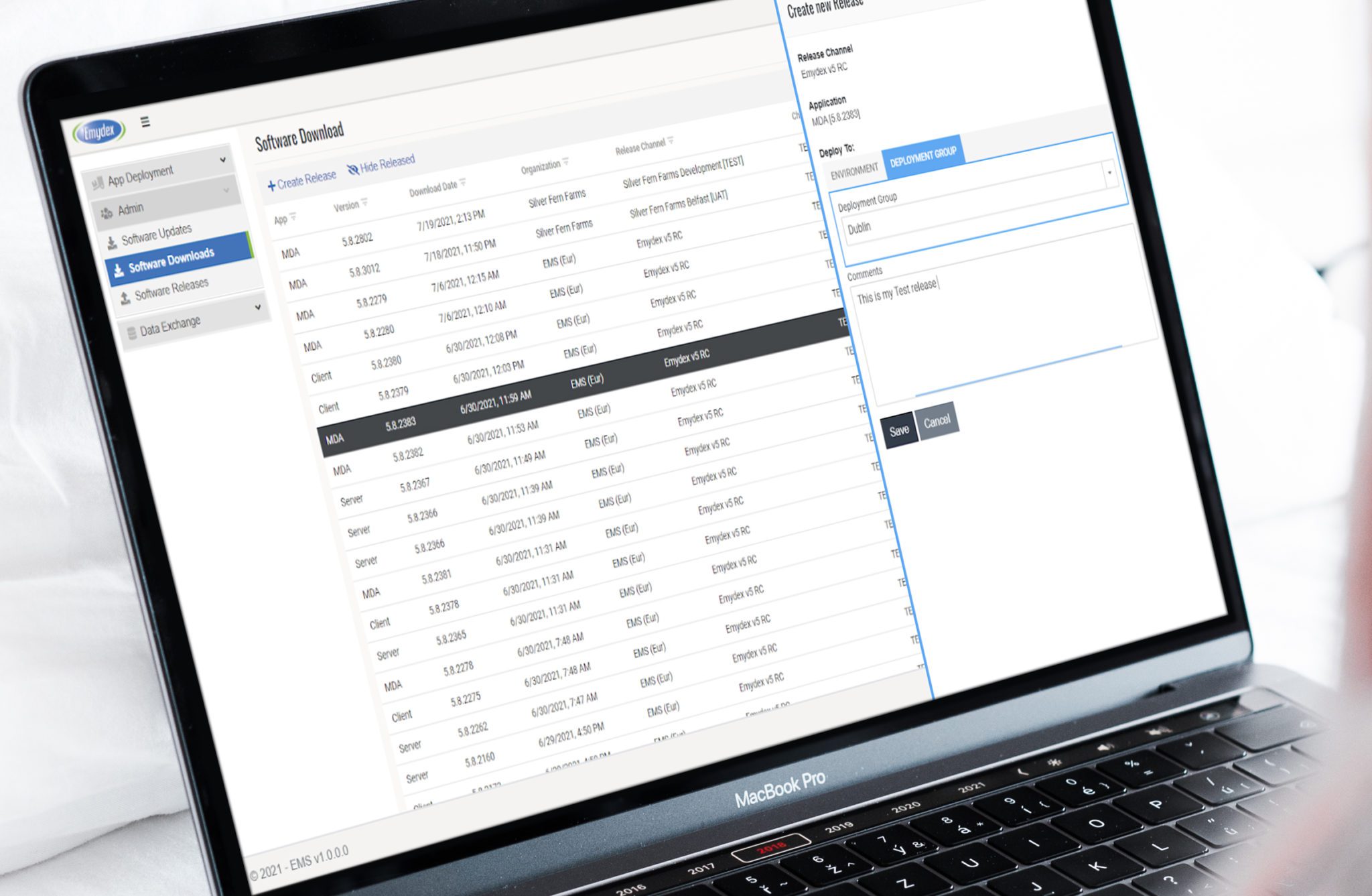

EMS App Deployment

This app empowers the Emydex customer's IT department to take control of deploying the Emydex applications out to the plants. This increases IT security and allows the IT department to pull updates into the business network to then choose when to deploy to the individual plants. This in turn allows the customer to be more self-sufficient in relation to updating plant's MES software outside of production.

EMS Exchange

EMS Exchange is Emydex’s newest approach to integration between the plants and third-party systems such as ERP systems and cold stores. It allows for the configuration of rules to route data from one system to other(s). This reduces the customisation required to integrate the Emydex applications into other third-party systems

Enterprise Quality Management System (EQMS)

Emydex’s first Enterprise module was the Enterprise Quality Management System (EQMS) which allows customers to centrally control, capture, store and report on various quality & technical aspects of their operations.

Find out more here…

The Future of EMS

The Emydex new product development team are busy working on new apps and features to further extend and enhance our offerings, including additional EMS modules such as Centralised Product Specifications, Production Planning, Payments, Livestock Appointments and Yield Costing.

Watch this space!

If you want to learn more – contact Ireland, Australia, South Africa or North America offices