When Staunton Foods first partnered with Emydex in 2014, the goal was clear: build a production management platform capable of supporting one of Ireland’s leading pork processing plants with reliability, accuracy, and visibility. Over twelve years later, that decision has shaped a digitally enabled factory environment that continues to evolve and support the company’s growth and reputation for quality.

A Heritage Processor with Modern Ambition

Staunton Foods, based in Timoleague in the heart of West Cork, has long been recognised as one of Ireland’s leading pork processors. Established decades ago and deeply integrated into the regional agricultural economy, the business has always prided itself on quality, animal welfare, and operational integrity.

By 2014, the plant’s throughput and increasing data demands meant its older legacy factory-floor systems supporting kill-line operations, livestock payments, and boning-hall reporting were being pushed to their limits. Stauntons needed a platform capable of meeting modern demands, not just in performance, but also in compliance, traceability, and integration with financial and partner systems.

Introducing a Digital Backbone for the Kill Floor

The first phase of the collaboration focused on modernising kill‑line operations. Emydex introduced structured data capture at lairage, grading, and slaughter points, enabling Staunton Foods to shift from fragmented legacy processes to a single, consistent source of operational truth.

Key benefits from this foundation included:

- Greater accuracy in livestock payments: Reliable grading, consistent data capture, and clear traceability records helped establish full transparency for producers supplying the plant.

- A unified view of kill‑line performance: Daily operations became easier to analyse, enabling supervisors to identify issues earlier, reduce variation, and maintain throughput targets.

- Confidence in compliance and audit readiness: With consistent, structured data in place, Staunton could respond more effectively to retailer, regulatory, and customer audit requirements.

Extending the Platform to the Boning Hall and Beyond

Following the successful stabilisation of kill‑line processes, Staunton Foods extended its Emydex system into the boning hall and downstream production areas. This included support for:

- Yield reporting and loss identification

- Stock visibility across raw, WIP, and finished goods

- Handheld scanning for movement, labelling, and dispatch

- Packing and palletisation workflows

- Enhanced traceability linking carcass data to downstream outputs

Operators benefited from simpler workflows and fewer manual touchpoints, while supervisors gained more precise insight into cutting yields, material usage, and batch-level performance.

For a business with high throughput, narrow margins, and strict quality requirements, this transparency has been pivotal.

Integrations that Strengthen the Business

One of Staunton Foods’ most significant long-term advantages has been the integration of Emydex data with financial and partner systems. Over the years, interfaces have been introduced and refined to support:

- Sage accounting

- XML data exchange with partner processors and cold stores

- Automated consolidation of production and commercial data

This connected ecosystem means operations are no longer siloed. Instead, the company benefits from an information flow that joins production, finance, planning, and logistics into a cohesive picture.

Resilience Through Continuous Improvement

What makes the Staunton–Emydex partnership stand out is not only the depth of the system but the consistency of improvements over more than a decade. These have included:

- Performance tuning to keep pace with throughput growth

- Software updates and compatibility enhancements

- Adjustments to accommodate new commercial requirements

- Improvements in handheld scanning and data‑capture workflows

- Extensions to reporting and operational visibility

This pattern of steady enhancement has ensured the system never stagnates and continues to evolve alongside Staunton’s needs.

A Perspective from Staunton Foods Management

For us, reliability is everything. The plant moves fast, and we need systems that keep pace without getting in the way. What Emydex has delivered over the years is consistency: consistent data, consistent performance, and consistent support. It gives our team confidence on the kill floor, in the boning hall, and in the office. Emydex has grown with us. We consider it an integral part of how we manage our business today”

John O’Regan, Staunton Foods Management

Unlocking Smarter Decision‑Making

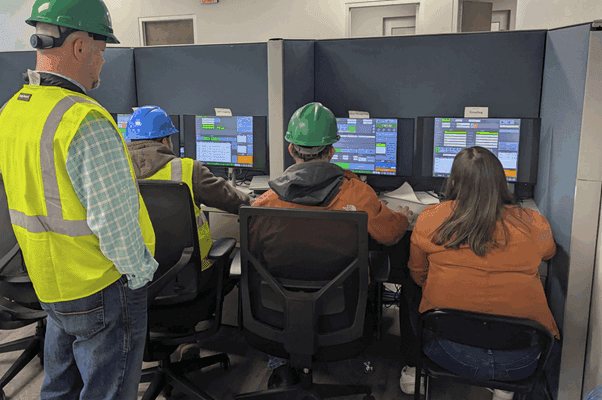

Today, Staunton Foods uses its Emydex environment not just as a transactional production tool but as an operational intelligence platform. Supervisors and managers benefit from:

- Clearer trend analysis based on multi-year data

- Better forecasting informed by accurate yields and run‑rate insights

- More proactive decision‑making informed by real-time visibility

- Faster resolution of issues uncovered by transparent data flows

This has helped strengthen margins, control waste, and improve operational discipline across the factory.

Supporting a Sustainable, Future-Ready Irish Processor

As the Irish pork sector faces competitive pressures, regulatory expectations, and rapid shifts in market conditions, the partnership between Staunton Foods and Emydex provides a stable foundation for continued growth.

Staunton’s commitment to maintaining a modern, data-driven production environment ensures the business remains resilient, responsive, and aligned with evolving industry demands.

A Partnership Built to Last

Twelve years on from the original go-live, Staunton Foods continues to rely on Emydex as a key strategic partner, not just a software vendor. The relationship is defined by collaboration, mutual trust, and a shared goal of maintaining one of Ireland’s most respected pork-processing operations.

The result is a quiet, steady success story: a modern MES driving real value in one of Ireland’s most traditional industries.

Interested in how a data-driven MES could support your processing operation?

Speak with our European team to explore how Emydex works in practice.

Schedule a meeting