Emydex is proud to announce the successful go-live of its Production Management (MES) and Quality Management (QMS) software systems at Sustainable Beef, a newly launched state-of-the-art beef processing facility in North Platte, Nebraska, USA.

After months of collaboration on design, validation, and testing, the Emydex North American team arrived on site in May 2025 to oversee the final setup, configuration, and support for the system’s first operational phase. This milestone marks the deployment of our newly developed Emydex Beef Industry Standard software solution across the plant. It strengthens our partnership with one of the most forward-thinking beef processors in the United States.

About Sustainable Beef

Founded with a vision to bring transparency, efficiency, and shared value to every part of the beef supply chain, Sustainable Beef’s North Platte facility now employs over 850 local people and is designed to process up to 1,500 cattle per day at full capacity. The plant is projected to contribute more than $1.2 billion annually to Nebraska’s economy, underscoring its commitment to community-driven beef production and regional growth.

Initial Contact

The journey began in March 2023, when Sustainable Beef’s project consultants selected Emydex as their MES partner, citing our proven ability to integrate with modern, complex plants and deliver robust, scalable solutions. This was no ordinary implementation. The entire business, including construction, equipment, people, and processes, was being built from the ground up. Agility, deep industry knowledge, and adaptability were essential throughout the project cycle.

Requirements Analysis

Most requirements analysis was conducted remotely via online workshops, mapping the ‘expected future state’ of a plant still under construction. Challenges included undefined SOPs and uncertainty to hardware locations, as many staff were hired only close to go-live. Emydex visited the plant in November 2024 to review key processes and touchpoints, incorporating US-specific requirements such as Packers and Stockyards Act compliance and USDA grading processes into our solution.

Implementation & Testing

Leveraging our new Beef Industry Standard design and reusable components, Emydex minimised custom development and accelerated timelines. The Emydex Beef system delivered to Sustainable Beef required few development changes, with configuration and training managed by an Emydex team of project managers, business analysts, and software engineers on site. Rigorous testing, including dry runs of the kill floor chain using ‘orange cows’ (orange builders’ buckets) ensured system stability and readiness for live operations.

System Go-live

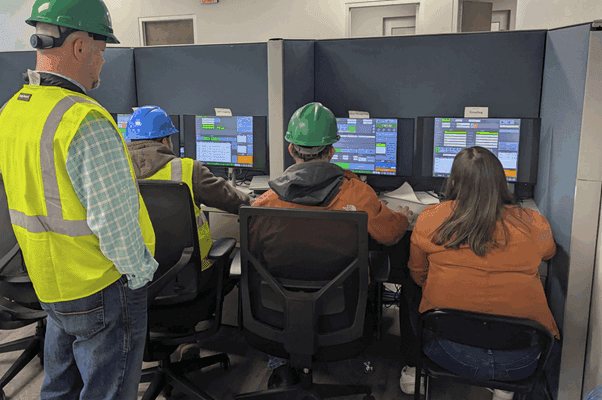

In June 2025, Emydex supported Sustainable Beef through a phased go-live approach, starting with core MES and QMS functionalities. Our on-site team worked side-by-side with plant personnel to:

- Validate real-time data flows across grading, ERP, and labelling systems.

- Provide hands-on training for operators and supervisors.

- Troubleshoot and fine-tune integrations with MEQ grading, Vande Berg Scales, and Business Central ERP.

The first cattle were processed under the new system without disruption – a testament to the collaborative effort and meticulous planning by both teams.

Customer Perspective:

Go-live today was a success! There were tense moments, but overall, today went very well. The hundreds of hours dedicated to this aspect of the plant opening and operating paid off. Our initial goal was achieved. ”

Kris Smith, Manager of Information Technology – Sustainable Beef, LLC

Post Go-live: Driving Continuous Improvement

Since go-live, Sustainable Beef has rapidly scaled production, recently surpassing 1,300 head in a single day. Emydex continues to provide:

- Remote and on-site support to optimise workflows.

- Performance monitoring to ensure system reliability.

- Integration enhancements, including connections with FPEC for trim products and EDI updates for major customers like Walmart.

These efforts ensure Sustainable Beef remains at the forefront of traceability, efficiency, and compliance, setting a benchmark for the US beef industry.

Customer Perspective:

We’re moving from reactive mode to steady development. The system is central to our operations and is helping us ramp up production efficiently.”

Manager Sustainable Beef, LLC

A Foundation for the Future

With production ramping up and systems delivering real-time insights, Sustainable Beef stands as a blueprint for transparent, efficient, and community-focused beef processing. For Emydex, this project represents a significant milestone in the United States and a reference point for future growth in the region.