HJ Nolan Ltd have been in business for 95 years, since 1912. The company sells premium seafood products worldwide, mainly smoked salmon, under the well-known ‘Nolans Seafoods’ brand. Today the company employs almost 300 people across its two Seafood processing facilities in Dublin, Ireland and Aberdeen in Scotland.

HJ Nolan approached Emydex Technology and SF Engineering in 2014, with a request to commission a new salmon filleting and trimming line from SF Engineering, integrated to an in-line real-time Yield and Efficiency reporting software system from Emydex Technology.

Sean Carolan, IT Manager with HJ Nolan’s in Dublin explains the background to the project, “before the Emydex and SF Engineering solution was implemented, all our salmon filleting was done manually. This resulted in us being unable to calculate our yields until the end of the working day, and this calculation was done with pen and paper. This process was time consuming and often lead to inaccuracies and mistakes. As our production started to ramp-up, we found it increasingly difficult to manage this process, and it became necessary to find a way to automate this process.”

Automated Yield Reporting

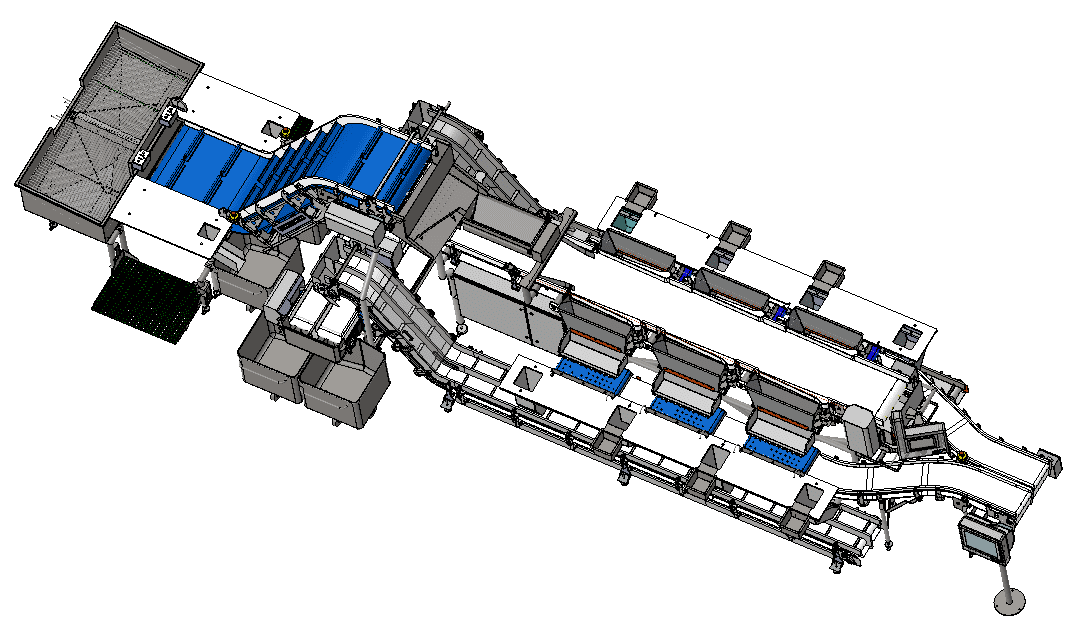

SF Engineering and Emydex set to work with Nolans to design and build the end-solution required. This exercise resulted in a SF Engineering salmon filleting & trimming conveyor line, complete with an In-feed holding bin, de-heading station, weigh hopper and a distribution conveyor that feeds the salmon to six salmon filleting operators working on the line. Each individual operator station consists of a buffer hopper, a holding hopper, a trimming table, an offal chute and a reset button.

SF Engineering Salmon Filleting and Trimming System

SF Engineering Salmon Filleting and Trimming System

To operate the system, each salmon-filleter working on the conveyor line first presses their reset button. This triggers the holding hopper to retract, and a new salmon falls into the hopper from the buffer hopper. The filleter then removes the fish to complete their trimming tasks, and once completed, places the fillet back onto the magenta weighing conveyor. The conveyor records the weight of the fish, and then waits for a free space on the takeaway conveyor. Once free, the conveyor sends the fish off to the pin-bone machine. When the operator’s holding-bin is emptied, the operator presses the reset button, starting the whole process all over again.

Cloud-Hosted or On-Premise

During each operation cycle, Emydex’s Data Capture System (DCS), captures each individual filler’s production data, and calculates the batch yield in real-time. Sean Carolan explains “the Emydex software system allows us to capture accurate yield data; weight-on versus weight-off, as well as production throughput; time-on versus time-off, from each individual filleter in real-time. This information is stored in a central cloud-hosted Emydex database, that can be viewed by both operators on the line, as well as our production supervisors on an industrial monitor running Emydex in the factory.

Real-Time KPI Reporting

Displaying production data and KPIs as they are happening in real-time, tends to have a motivational effect on the filleters working on the line, and improves operator productivity. Emydex production reporting can also be accessed on client PCs in the back-office, as well as anywhere around the world via a smart-phone, given the system is hosted in the cloud”.

On-floor Production reporting monitor displays individual filleter yields and throughputs accurately in real-time

On-floor Production reporting monitor displays individual filleter yields and throughputs accurately in real-time

Carolan Continues “The ability to export accurate information instantly from the Emydex system, has greatly improved the process by which the filleters are paid. Before the implementation of the Emydex system, the production supervisor would have had to manually calculate each filleters weights and rate of pay. This information can now be exported and sent directly to our accounts department. The individual yield of each filleter can now be much more closely monitored by their supervisor. This allows us to insure each filleter is maintaining a satisfactory yield throughout the day.”

Traceability Reporting

“In addition to Yield and efficiency reporting, Emydex is also recording and reporting on food chain traceability throughout the production process” outlines David McMahon, Emydex CEO. “traceability details recorded for each batch include the Emydex ITN (Internal Traceability number), Production run, Supplier, Harvest Number, Harvest Date, Product, Species and size. Same as for production reporting, traceability reporting is available instantly and accurately, from any device connected to the central database in the cloud. Optionally, the system can be hosting on-site/on-premises if required”.

Customer Support

Sean Carolan concludes “Emydex offered unwavering support to Nolans from the onset of this project. Throughout the initial design process, the implementation and the aftersales support, Emydex has maintained an unparalleled level of support and professionalism. It’s always a pleasure dealing with anyone from the Emydex team, and I wouldn’t hesitate to recommend them to anyone in the market for reliable, well-supported factory floor software solution.”

About Emydex Technology: Emydex Technology is a leading supplier of Traceability reporting and Production Management Software systems to Meat, Fish and Food Processors around the world. Over 100 food processing factories, operating across 4 continents, use Emydex factory floor software systems to monitor, control and report on their Production yields, stocks, traceability, food quality, safety and compliance.

About SF Engineering: SF Engineering is an award-winning Irish engineering company that designs and manufacturers food processing and packaging solutions for the food industry globally. The company’s Engineering solutions are operating in meat, fish and food processing companies throughout Europe, Russia, the Middle East and Chile

About Emydex & SF Engineering: Emydex Technology and SF Engineering have worked on a number of joint software/hardware integration projects for shared customers over the past number of years. In addition to the salmon filleting line solution delivered to HJ Nolans, other joint projects including Emydex integration to an SF Engineering pork primal grading line, as well as integration to RFID controlled SF Engineering conveyor systems operating in a lamb Processing plant in the UK.