WINDHOEK – NAMIBIA:

Emydex today announce that their factory floor Data Capture, Production Reporting and Traceability system is now live and operational in MeatCo (Namibia)’s main beef processing plant in Windhoek, the capital of Namibia.

The beef primal deboning system in Windhoek is the first of an eight phase project that will see Emydex systems rolled out across MeatCo’s six beef processing operations in four separate locations in Namibia, as well as integrating Emydex to the Table Bay Cold Store in South Africa.

The two year, Euro 300k contract includes system rollout to Meatco’s two export approved slaughter and boning plants in Windhoek and Okahandja. Both plants are capable of slaughtering up to 1500cattle per day. The naturally grass fed Beef for which Namibia is famous is supplemented with Beef from Meatco’s own feed lot at Okapuka.

The Meat Corporation of Namibia (‘MeatCo’) also operate two further non-export abattoirs owned by the Namibian government but managed by Meatco, in Katima and Oshakati, which will both see Emydex installed. Finally a Wholesale beef processing plant and a cannery (both on the Windhoek site) will operate Emydex’s production management system.

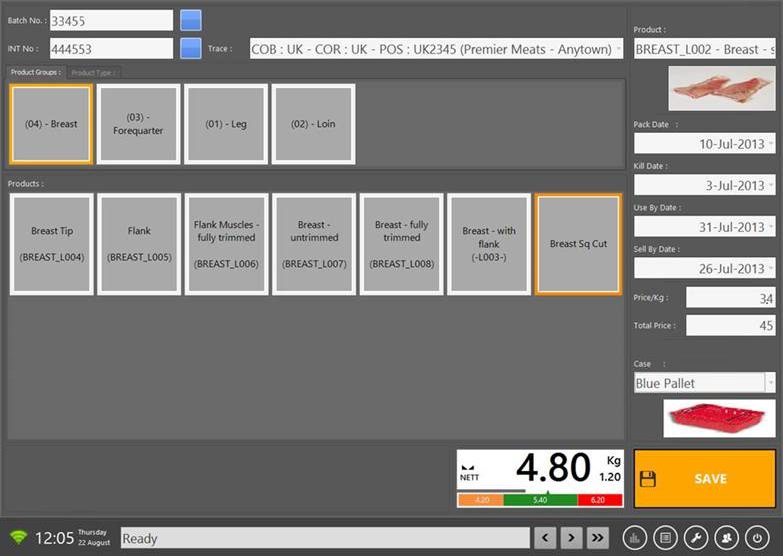

Having pre-configured MeatCo’s customer specific business requirements in Dublin during February, Emydex staff were onsite in Windhoek during the Months of March and April, further configuring and customising the Emydex system to comply with the local market requirements of Meatco’s main export plant.

Phase one of the Windhoek project covered the carcass chills, carcass dispatch, boning hall, primal and carton packing, finished product stock, carton dispatch and integration to Meatco’s Sage X3 ERP system. Emydex are currently working on the Meatco Wholesale plant in Windhoek, soon to be followed by the Cannery and finally the Windhoek Beef slaughter line.

The company are targeting September 2014 as a likely roll out date for Windhoek system into Meatco’s second export plant in Okahandja.Due to the inherent flexibility and usability of the Emydex system Meatco are planning to roll out the Emydex system in the Oshakati and Katima abattoirs themselves,with remote support from Emydex as needed.

Commenting on the first phase of the Emydex system roll-out, AndriesTaljaardt,Meatco’s Windhoek Plant Manager said

“While slaughter continues uninterrupted, system upgrades are currently being effected at our Windhoek abattoir to improve the effectiveness of operations and maximise output in order to cater to growing customer demands.

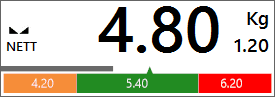

Because of these demands, and the fact that preferences and specifications are continuously changing, we have to move into the direction which the market is moving. We have installed a new Production Management Software System (Emdyex) and layout in our Windhoek abattoir deboning department, which allows for a lot of value addition to our products. The Emydex system controls the volumes and all the information on the deboning floor and is responsible for the production recons and the labelling of products.

With the new layout, we have introduced an additional vacuum line and an additional frozen line. With that, we can now put up to 420 carcasses through deboning per day within normal working hours. For May, we are looking to put more than 6600 carcasses through deboning. Round about June, once the system is fully implemented, the number of carcasses we want to put through deboning is about 7000.”

In addition Andries said “We chose Emydex given it is a highly technological system that is used in many international abattoirs that adhere to European Union standards. Meatco is a pioneer in quality standards compliance in Namibia and is one of the first companies to achieve certification for international standards like ISO 9001 and HACCP.”

Commenting on the Emydex system roll-out, Nico Weck, Group Chief Financial Officer at the MeatCo group said “since implementing Emydex’s shop floor barcode labelling and scanning system at our Windhoek primal deboning operations, our managers now have instant access to accurate reporting on our Yields, Stocks and Traceability”.