Processing over 1.4 million packs of chicken every week and supplying all major UK retailers, Forresters Chicken operates in an environment where efficiency, quality and traceability are critical to daily operations.

With more than 50 years of history, the business had grown significantly. But as production volumes increased, so did the complexity of managing quality, performance and compliance across the factory floor.

Like many food processors, Forresters reached a point where traditional, paper-based processes could no longer support the pace and scale of the operation.

Before Emydex, all of our quality control processes were paper-based. Everything was pen and paper, reams and reams of paper, and traceability was a nightmare.”

Angus Dilliway-Parry - Owner / R&D Director

Operational Visibility Before Digital Transformation

Paper-based quality checks and manual records made it difficult for teams to gain a clear, real-time view of what was happening across production.

From a management perspective, this lack of visibility impacted decision-making and operational efficiency.

From a management point of view, it was difficult to see the full picture at any one time.”

John Acornley - Finance Director

Without instant access to reliable data, reacting quickly to issues, monitoring performance and meeting production expectations became increasingly challenging.

The Turning Point: Moving from Paper to Real-Time Data

The introduction of Emydex marked a fundamental shift in how Forresters managed production and quality. What was once fragmented and manual became digital, structured and immediately accessible.

The difference between before Emydex and after Emydex is like night and day. The access to information is phenomenal.”

John Acornley - Finance Director

Real-time access to production and quality data transformed daily operations across the business.

Embedding Data into Everyday Operations

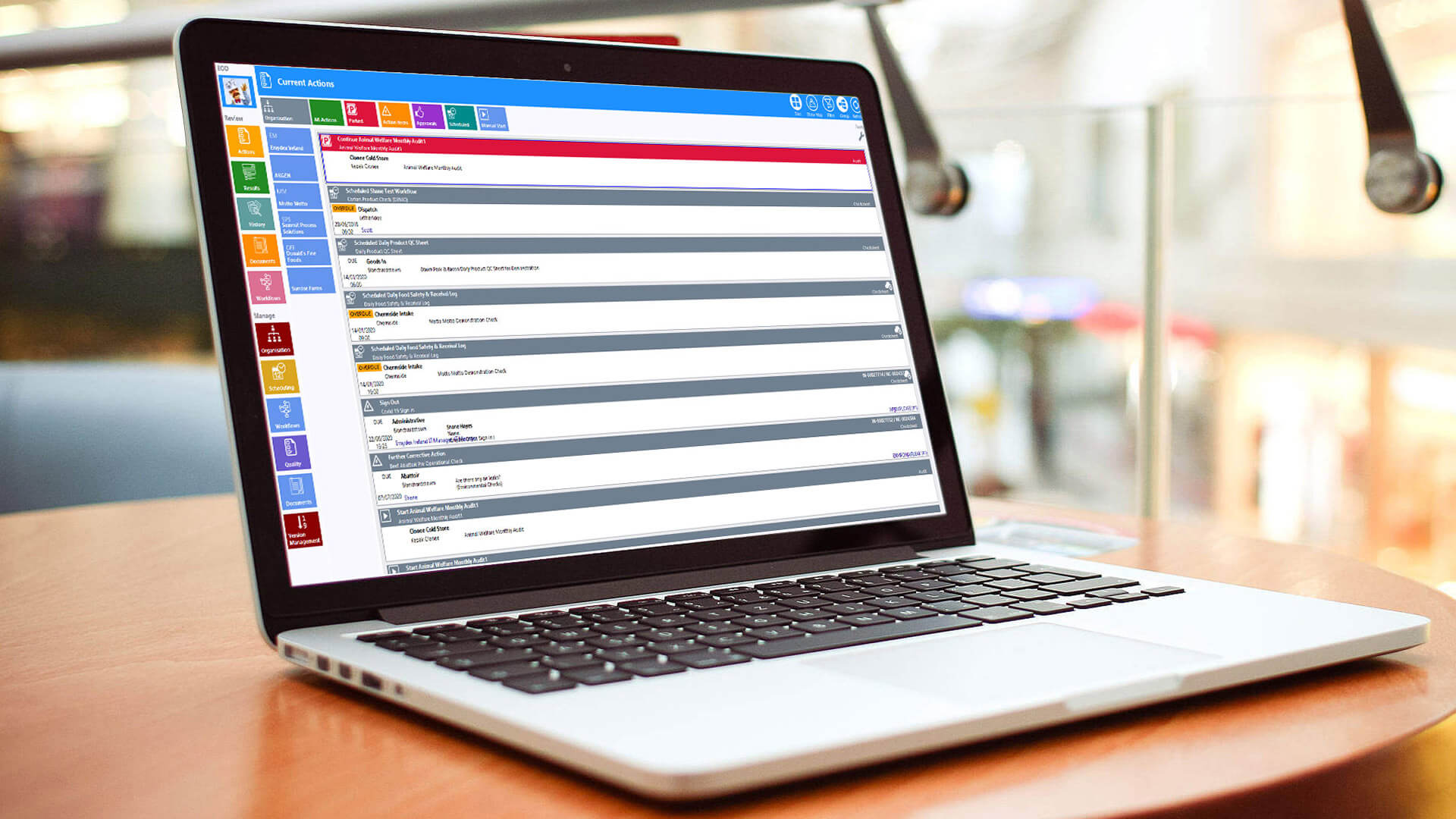

Today, Emydex is used consistently across the factory floor and beyond. Production planners, operators and managers rely on the system daily to support informed decision-making.

The planners use it day in, day out. The factory uses it day in, day out. We have screens up giving the staff and managers the data they need.”

Nick Cooper - Operations Director

This visibility extends beyond the physical factory.

Even if you’re not in the factory, you can pull up Emydex information on your computer and see exactly what’s going on.”

Nick Cooper - Operations Director

Turning Insight into Continuous Improvement

With accurate, real-time data available instantly, Forresters can analyse performance, challenge inefficiencies and drive continuous improvement.

Production metrics such as packing rates, throughput and giveaways are no longer retrospective. They are visible, measurable and actionable.

This data-led approach supports ongoing improvements across efficiency, yield and performance.

We use it as a tool to improve what we’re doing, efficiencies, line rates and giveaways.”

Nick Cooper - Operations Director

Stronger Traceability, Supported by Partnership

Alongside efficiency gains, traceability has significantly improved, providing confidence across audits, compliance and day-to-day operations.

Equally important is the long-standing relationship behind the technology.

Our partnership with Emydex has been fantastic for more than a decade. They’ve been responsive, innovative and collaborative.”

John Acornley - Finance Director

The value of that partnership extends beyond the system itself, offering accessible support and a personal approach.

Looking Back, Looking Forward

Reflecting on the journey, it’s clear that Emydex has become embedded in how Forresters operates.

Looking back now, you think, how did we manage without it before?”

Nick Cooper - Operations Director

Today, the business benefits from real-time visibility, improved efficiency and a stronger foundation for future growth.

It’s been a really good thing for our business. We really appreciate what Emydex does to help Forresters run efficiently every day.”

Nick Cooper - Operations Director

Want to see how real-time visibility and traceability can support your operation?

Learn more about Emydex’s Manufacturing Execution and Quality Management solutions or contact our team to discuss your requirements.