A leader in the supply of quality Irish beef products

Ashbourne Meat Processors is one of Ireland’s most successful exporters of premium chilled beef products. Founded in 1985, the company exports high-quality products all over the world and is proud to be recognised as a family whose expertise and knowledge is passed down from one generation to another. There are nearly 200 people in the company family working in two facilities in the centre of Ireland – Roscrea (slaughtering and cold-storage facilities) and Naas (deboning and cold storage).

Ashbourne Meat Processors is a firm believer in leveraging advanced technology and production facilities.

What Ashbourne Meat Says

“The savings in administration were immediate – we saved a labour unit in the office immediately – and the piles of paperwork and stacks of files are a thing of the past. We’re almost paperless now, except for the cheques which some of our more traditional farming suppliers prefer over electronic payments. I estimate that actual physical paperwork has decreased by 95% and that’s a huge achievement.”

PJ Butler, Roscrea Plant Manager, Ashbourne Meat Processors

Challenge

Ashbourne Meat Processors’ two plants were essentially working in isolation from each other on outdated systems that required a lot of manual input and data entry. The abattoir in Roscrea would take in livestock and create the relevant paperwork. When the carcasses were transferred to Ashbourne Meat Processors’ facility in Naas (and to other facilities operated by the company’s clients all over the country), new paperwork would have to be created. This was extremely inefficient and left the company open to human error, duplication and lack of visibility and control.

There were also issues with compliance as the legacy systems used in both operations were not integrated with the Department of Agriculture systems and so there was a need for even more data entry.

Solution

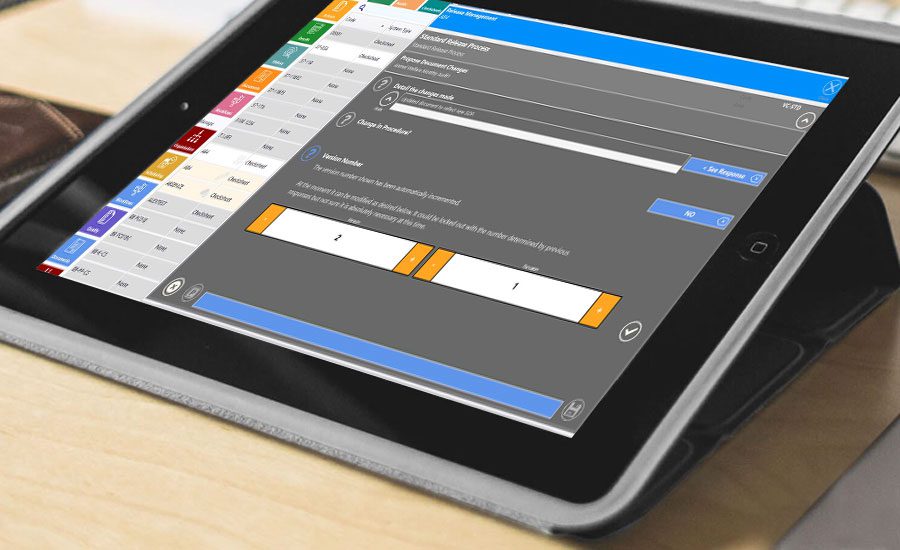

Emydex is the acknowledged leader when it comes to process development for the food industry and when Ashbourne Meat Processors decided to overhaul the IT infrastructure and embrace the latest processing technology, they called Emydex.

Following a project scoping exercise, the team agreed to divide the job into two phases – one for the slaughter plant in Roscrea and the other for the Deboning operation in Naas. Connecting the two facilities was an obvious but important improvement.

In phase one, The Naas Deboning operation was upgraded by Emydex to deliver an end-to-end factory floor solution. Today Emydex handles the entire processing procedures within this plant, from Intake, Into / Out of Boning, Packing, Dispatch and Warehousing. Emydex also generates all the appropriate Dispatch Documentation, transfers traceability data to customers and allows for full forward and backward traceability. Prior to Emydex’s introduction, Work Orders were paper-based and were phoned down to the operators. Now this is all controlled within Emydex which means there is less likelihood of human error and the whole process is now more streamlined and controlled.

In phase two, the abattoir and cold storage facility 100 kilometres away in Roscrea, County Tipperary, was completely overhauled with everything from animal intake, supplier POs, inter-company paperwork and all procedures – from processing to packing, including sales picking – newly streamlined and automated. Labelling from boning through storage and out in orders was part of the specification as was the automatic electronic generation of all documentation. Real-time data is now updated constantly between the two plants and a new dispatch system created.

Outcome

Animal intake at the abattoir is now seamlessly and automatically integrated with the Government’s veterinary body, AIMS. Ear tags are scanned and all animal data is confirmed and registered and the Department of Agriculture is notified automatically. This improvement alone saves thousands of man-hours every year and completely eliminates human error at the intake point.

There used to be two separate systems and all sorts of mistakes were created by so much manual data entry. This led to delays in cattle payments and problems in registering the passport details of some animals. Now there is just one system and those errors have been eliminated.

Everything from animal intake to carcass dispatch and box generation is automated, tracked, reported and visible all the way from start to finish.

Overall, and almost immediately, efficiency was improved, paperwork virtually eliminated, errors drastically reduced, and profitability increased throughout the company.

Beef Industry

Industry Updates

Emydex Software: A Game-Changer for Beef Processors

Emydex, a leading provider of software solutions for the meat processing industry, is celebrating its 20th anniversary in…

Find Out MoreEmydex 20 years – Central Agri Group

Central Agri Group Beef Primal Processor1 Plant in Victoria, Australia Emydex customer from 2016 – 2024 (8 years)…

Find Out MoreEmydex 20 years – Wilson Hellaby Ltd

Wilson Hellaby Ltd Beef & Pork Primal Processor 2 plants, New Zealand Emydex customer from 2020 – 2024 (4 years)…

Find Out MoreFarmer Bookings & Feedback via Livestock Portal

A new web-based appointment booking and feedback system.

Find Out MoreEmydex CAPS off year with Livestock Payments System

Emydex CAPS off the year with a new Livestock Settlements System For most Meat processors, the procurement of…

Find Out MoreTurning over a new leaf in New Zealand

Turning Over A New Leaf In New Zealand How Emydex helped the largest livestock processing company in New…

Find Out More