Recipe Formulation Software

Providing full management, control and traceability, the Emydex recipe formulation software is currently operating in over 30 Meat, Fish and Food Processing Plants around the world.

Having first gone live in 2011 in one of the UK’s largest beef processors, Dunbia (Preston), today our Recipe formulation system is in daily operation in many Emydex client sites producing a range of food products from Burgers, Sausages, Mince, to Sauces and Marinades, to Infant and Baby Formula.

Recipe Formulation

Benefits of our System

Recipe Formulation

System Features

Recipe BoM & Definition

The Emydex recipe BoM & definition controls standard batch sizes, ingredients, quantities/UoM, min/max tolerances as well as sequencing and substitutions for the recipe. Recipes can contain sub-recipes if required.

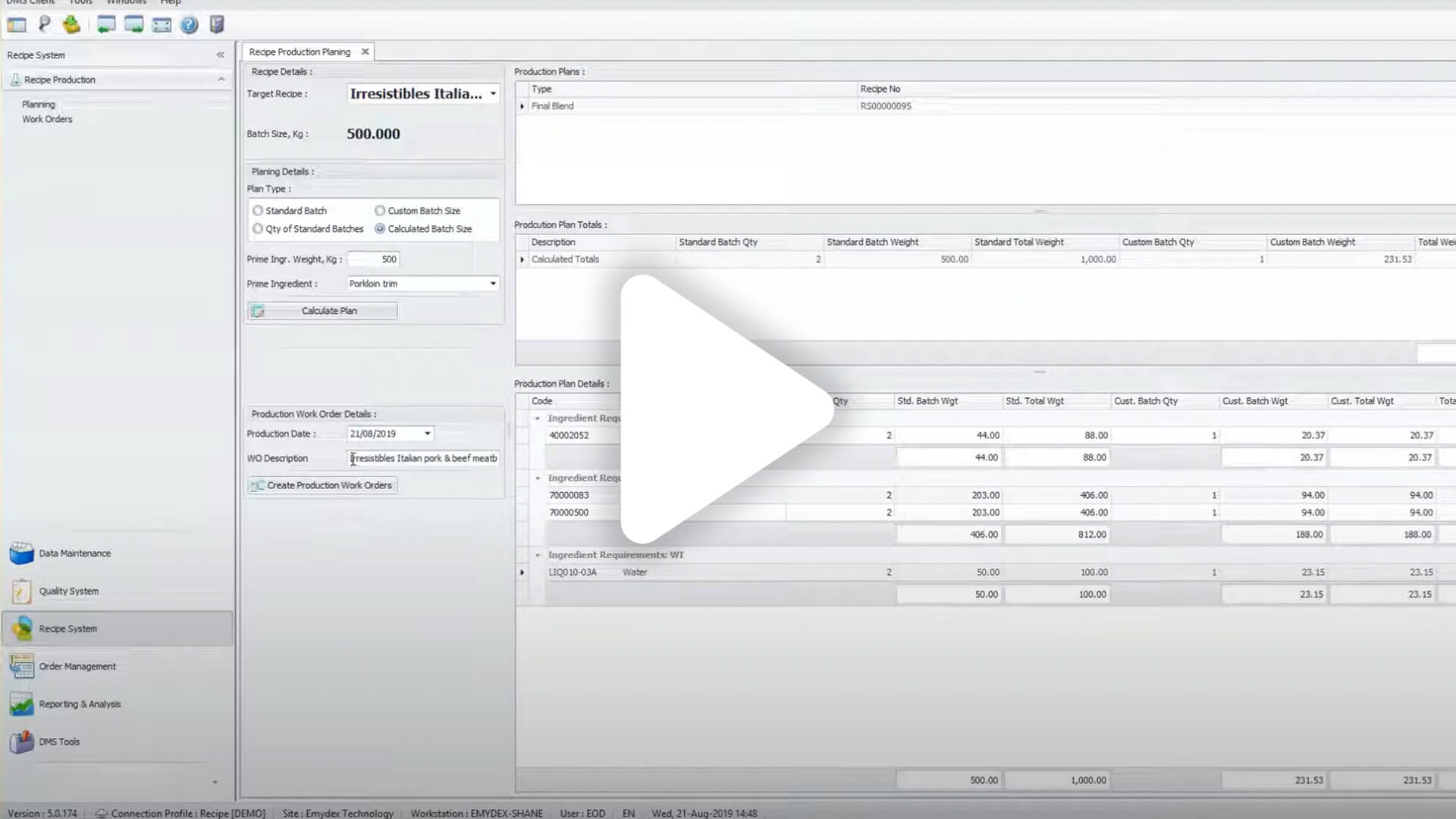

Recipe Planning

Plan your production using the Emydex recipe production planning system. This allows customers to plan based on standard batch sizes, custom batch sizes or a calculated batch size based on one of the raw materials. Plans can also be made based on sales orders that are either entered directly into Emydex of received from the ERP system.

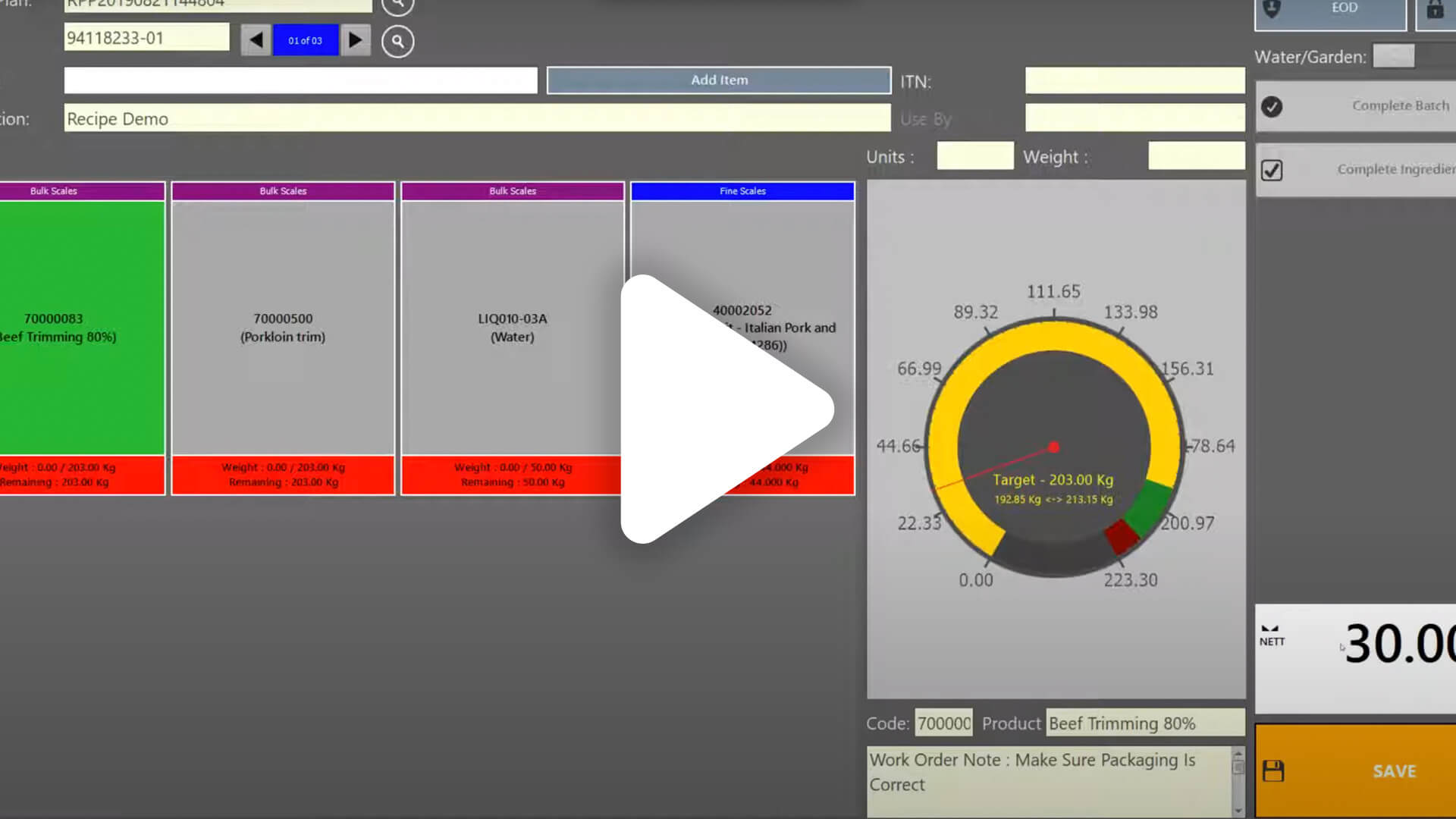

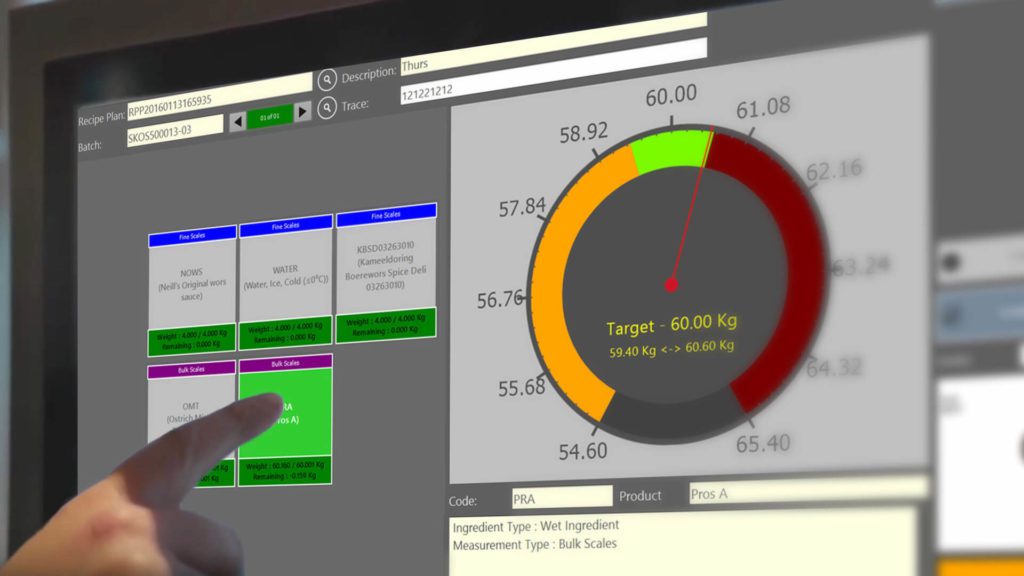

Recipe Blending

The Emydex recipe blending form provides users with an intuitive interface to control the inputs of the recipe. They are able to easily see the progress of each ingredient and ensures that operators follow recipe definitions for consistency. Terminals can have multiple scales connected to weigh different ingredients.

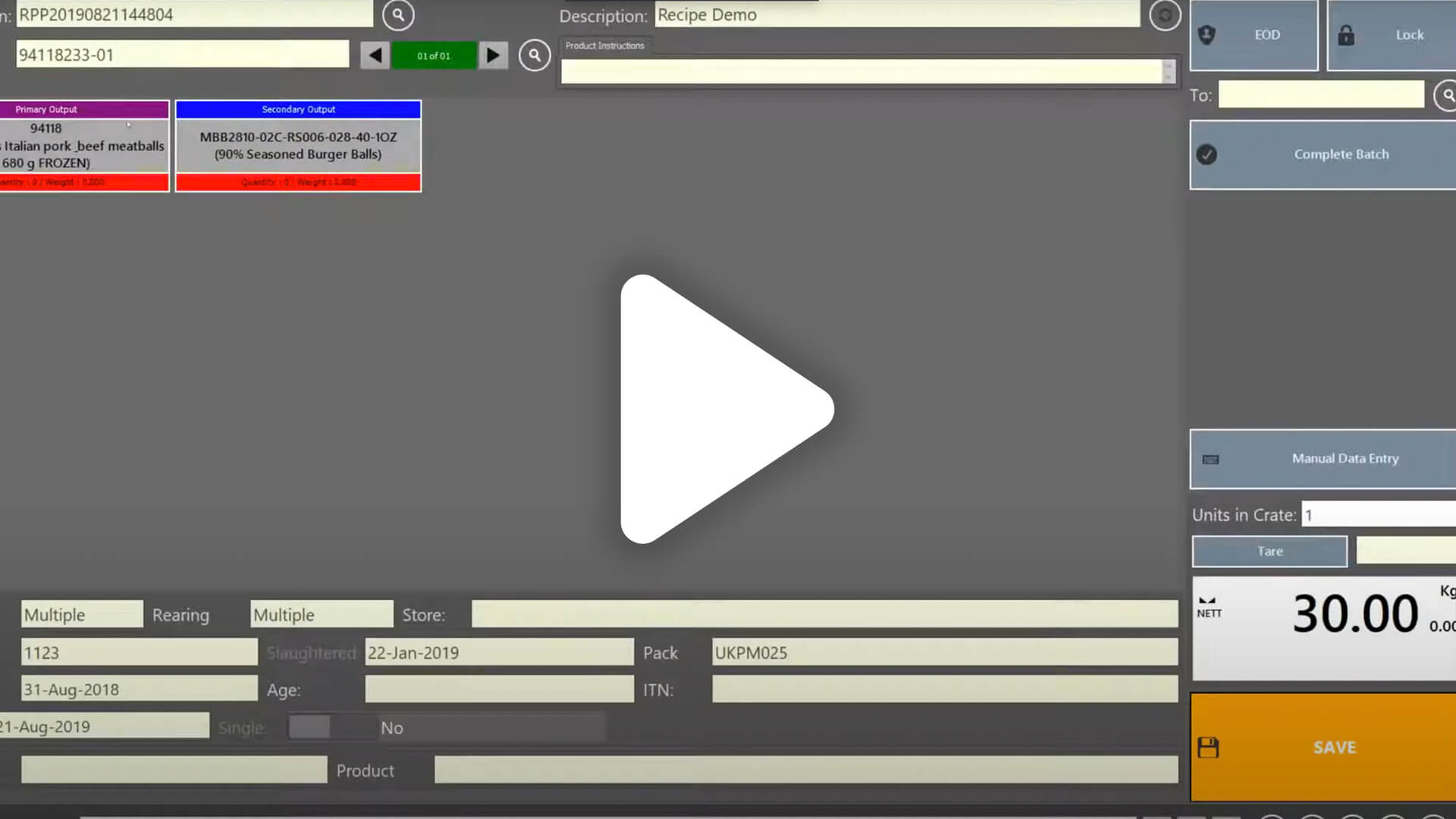

Labelling

The Emydex packing terminals can label work in progress (WIP) or finished goods from the recipe batch, maintaining traceability throughout the process. This allows customers to capture the output of the batch for traceability and yield reporting and will also create inventory items in the Emydex warehouse management system.

Job Processing

Customers are able to easily set up jobs for the various processes within the factory. This allows customers to scan into a work order & Job and produce a product from this which allows customers to maintain traceability and report on yields and efficiencies. E.g Tumbling, smoking, filleting, brining etc

Software Videos

Emydex Recipe System Demonstrations

Our Software

Recipe Definitions

Our Software

Recipe Planning

Our Software

Recipe Blending

Our Software

Recipe Weighing Out

Designed for your industry

Our software modules

The Emydex suite of software includes a collection of independent standalone software modules designed to manage and control a particular stage of the Food Production Process e.g. Kill Line & Livestock Payments.

Each modules sits on top of the core platform, and can plug seamlessly into any other module. The full suite of modules cover all aspects of Food production from factory door-to-door.

Emydex Explained

Our software provides real-time and accurate reporting of Production, Yields, Stocks, Quality and Traceability

Our News

Industry Updates

Emydex Software: A Game-Changer for Beef Processors

Emydex, a leading provider of software solutions for the meat processing industry, is celebrating its 20th anniversary in…

Find Out MoreDitch the Paperwork with Emydex Quality Management

Meat, Fish, and Food Processors Rejoice! Ditch the Paperwork with Emydex Quality Management Gone are the days of…

Find Out MoreEmydex is 20 Years in Business today

Emydex is 20 Years in Business today

Find Out MoreEmydex 20 years – Clogherhead Co-op

Clogherhead Co-op Seafood Primal Processor,1 Co-operative plant, 12 trawlers, Ireland Emydex customer from 2014 – 2024 (10 years)…

Find Out MoreEmydex 20 years – Oliver Carty

Oliver Carty Value Added Pork Processor, 1 plant,Co. Athlone, Ireland Emydex customer from 2011 – 2024 (13 years)…

Find Out MoreEmydex 20 years – Central Agri Group

Central Agri Group Beef Primal Processor1 Plant in Victoria, Australia Emydex customer from 2016 – 2024 (8 years)…

Find Out MoreEmydex 20 years – Silver Ferns Farms

Silver Fern Farms Beef & Lamb Primal Processor 14 plants, New Zealand Emydex customer from 2010 – 2024…

Find Out MoreEmydex 20 years – Wilson Hellaby Ltd

Wilson Hellaby Ltd Beef & Pork Primal Processor 2 plants, New Zealand Emydex customer from 2020 – 2024 (4 years)…

Find Out More