A successful family-run food business

Corries Farm Butchers was established in 1977 by Willie Corrie. Since then, the business has built a successful family meat and food business and now have three sons, William, Gareth and Richard who are all deeply involved.

Located on the Ards peninsula, Corries is now a thriving retail and wholesale business. They farm 1,100 head of beef and 850 dairy cows across 1200 acres with quality and the provenance of beef production paramount to their retail business.

Working with Emydex

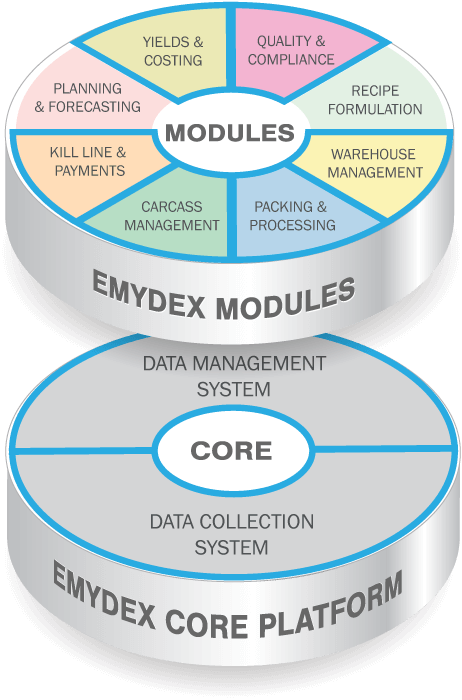

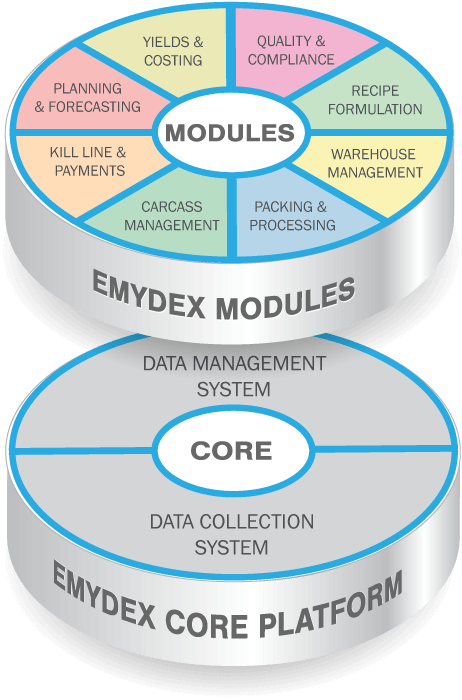

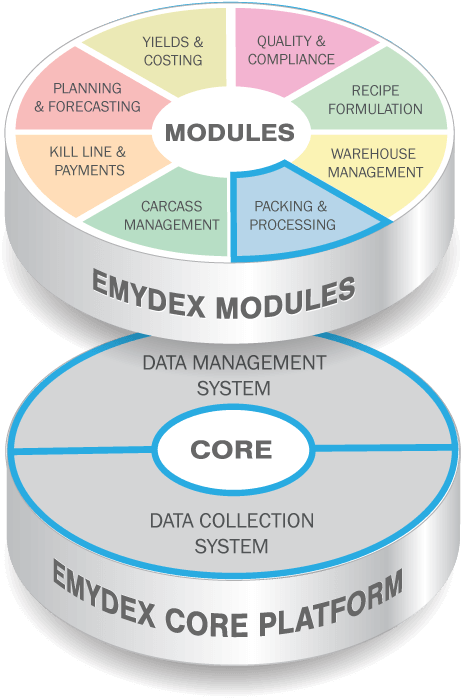

Since 1977, Corries Meats have proudly ensured only the finest quality meat leaves the manufacturing premises at ‘The Farm’ on the Newtownards peninsula. Corries implemented Emydex’s Packing & Processing and Warehouse Management Modules throughout their factory to assist them.

Our News

Industry Updates

Dawn Pork & Bacon, 17 years on Emydex and counting

Emydex was founded in April 2004, so Dawn P&B was one of the very first customers to go live with an Emydex software system.

Farmer Bookings & Feedback via Livestock Portal

A new web-based appointment booking and feedback system.

Emydex CAPS off year with Livestock Payments System

Emydex CAPS off the year with a new Livestock Settlements System For most Meat processors, the procurement of…

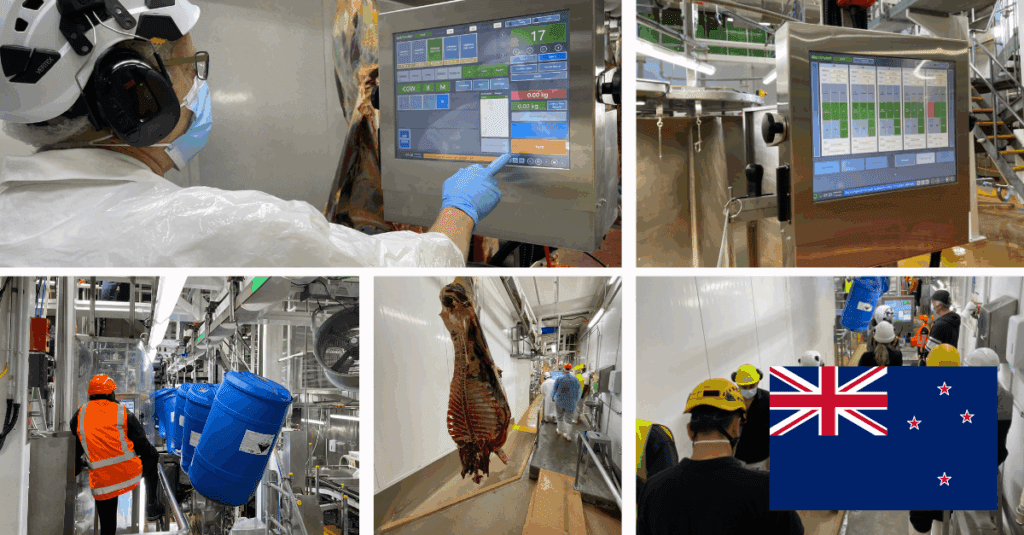

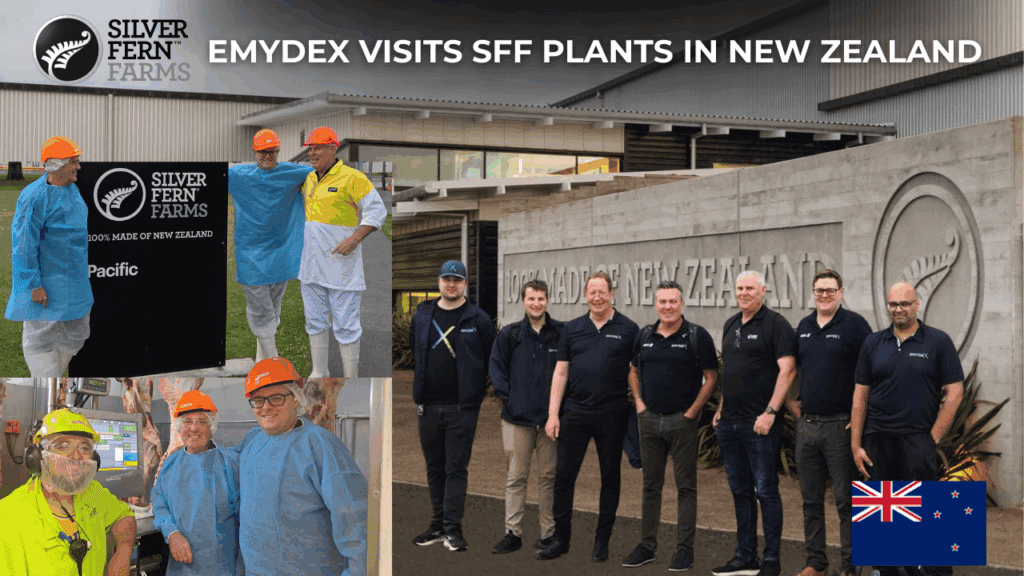

Turning over a new leaf in New Zealand

Updated in September 2025. Turning Over A New Leaf In New Zealand How Emydex helped the largest livestock…

Eliminate costly carton rejections with Emydex and Meat Messaging

The international trade of food products has over time become highly competitive with many large multinational companies emerging…

Improvements by the country mile

Meet the client Ashbourne Meat Processors is one of Ireland’s most successful exporters of premium chilled beef products….