A leading UK supplier of cooked and raw poultry

Established in 1972 and based in Cheshire, Forresters is one of the largest suppliers of cooked, raw and coated poultry in the United Kingdom. The company supplies retailers, food services, pub retailers, manufacturers and catering butchers with a variety of frozen and chilled branded and own label chicken products.

Working with Emydex

“The Emydex system is very efficient, easy to operate and works well for us. The full traceability we have gained saves masses of time – what used to take the QA department days to analyse is now instant. Emydex never say they can’t do something: they’ll listen and go away and come back with an answer, they always find a way.”

Heidi Dilliway-Nickson, Director with Forresters

Challenge

Forresters had the expertise, the market and the reputation to help them to take the business to the next level. The issue was with operations and one of the biggest hurdles was the fact that their existing production and billing systems were built in-house and not integrated to their back-office ERP system. In practical terms, the production lines couldn’t handle any more as they were currently configured.

Maintaining and updating the systems was costly with little support, resulting in an over-reliance on a few key individuals. In addition, Forrester’s was unable to report in real-time on their daily production, stocks, traceability, yields and costs.

Solution

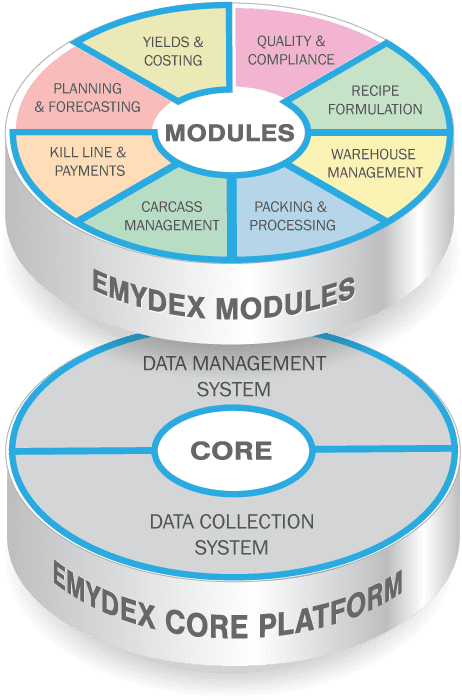

Forresters managers and Emydex specialists worked closely together to work out how to blend the best technology with the company’s own expertise to create an operation that could upscale as needed. Forresters commissioned Emydex to develop a production management and traceability reporting system which would operate on the shop floor and in the back-office for data maintenance, analysis, trending and reporting.

We began with phase one which was the installation of our packing and processing module on a dozen shop floor weigh-price labelling packing terminals. The Emydex weighing and labelling software system for finished products features easy-to-use label design, compliant with all EU regulations.

With that up and running we moved on to phase two which covered the roll-out of a factory-wide solution that covered the entire line. It was designed to give full traceability from start to finish, from intake of the raw material by purchase order, defrosting, cooking, production work orders, marination, packing, analysis by retail line, full stock, yield and dispatch control and then on to Sage 200 accounts for invoicing.

Outcome

This system is now live on the factory floor, door-to-door including all of Forresters fixed weight lines. The biggest and most immediate benefit of the new Emydex system is the reduction of manual input which has eliminated the risk of human error. Packing is now fully automated and labels are printed automatically when the correct number and type of packs are in the box, saving time, resources and money.

Forresters now has complete visibility over their entire production management process. They are no longer reliant on key individuals to manage in-house systems and they have a full support team on hand should any issues arise.

Most importantly, the Emydex system provides management and supervisors with real-time and accurate reporting on factory stocks, production, as well full traceability reports.

Profitability is up, human error has been eliminated and the factory has scaled up as a direct result of the improvements in efficiency and production brought about by the Emydex solution.

Poultry

Industry Updates

Kill Line Live in Central Agri Group, Victoria, Australia

In 2016 Central Agri Group, formerly Central Meat Exports, re-opened their newly refurbished beef plant in Trafalgar as…

Find Out MoreRosie & Jim Value Added Poultry Processor live on Emydex

Dublin – Ireland: Rosie and Jim was established in 1997 when award winning craft butcher, Jimmy McLoughlin established Quality…

Find Out MoreEmydex Live in World’s Largest Ostrich Processor

OUDTSHOORN – SOUTH AFRICA: World’s Largest Ostrich Processor Established in 1985, Klein Karoo is the world’s largest Ostrich…

Find Out MoreBeef Processing Software Live in MeatCo Namibia

WINDHOEK – NAMIBIA: The Emydex implementation team returned to Ireland after the latest phase of Emydex system deployments…

Find Out MoreTraceability System Live in La Rousse Foods

DUBLIN/BELFAST – IRELAND: With operations located in Dublin and Belfast, La Rousse Foods specialise in the supply of…

Find Out MoreAllergen Labelling, upgrade to an Emydex Traceability system.

New EU Food Allergen Labeling Regulation By December 13th 2014 all food labels in EU must identify allergens…

Find Out More