Emydex 4.0 upgrade

In line with Microsoft’s release of .NET 4.0 / 4.5 frameworks, Emydex took the opportunity to focus our Product Development team’s attention on a number of area’s we felt could be improved upon

The Emydex 4.0 release focuses on both the user interface ‘look and feel’ and ease of use of the Emydex system, as well as performance improvements. Many of the improvements arise on the back of enhancements in .NET and as such .NET 4.0 / 4.5 is the minimum framework requirement for this latest Emydex release

Metro Theming

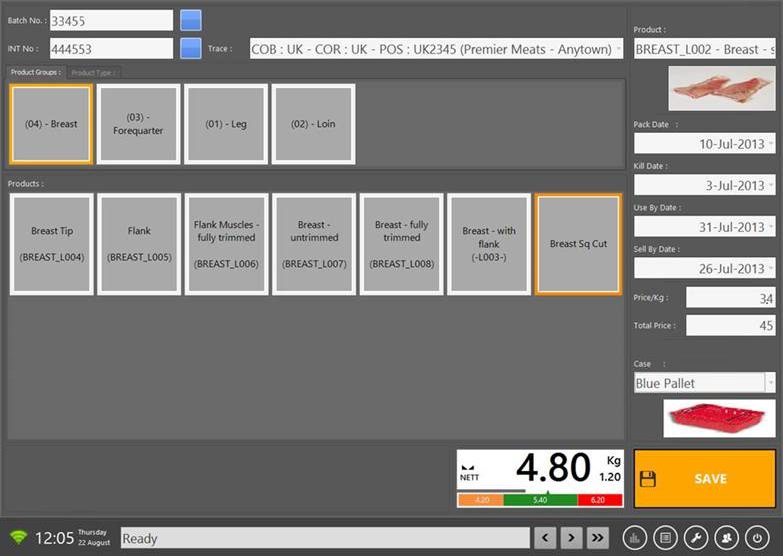

In tandem with the release of .net 4.0/4.5, Microsoft also released the new Metro design language. This set of guides and best practices were compiled by Microsoft for use with applications targeting touch type interfaces. For Emydex 4.0 we worked on both the MDA (Mobile Device Application, typically used on rugged toughbook devices etc.) and SDA (handheld scanning terminal) theming to incorporate these guidelines.

We opted for a dark theme after doing tests under the sort of lighting conditions found on factory floors. Emydex also refreshed our iconography for both of these apps, opting for simpler, clean, icons over more detailed ones. Finally we have reduced the amount of variance in our colour pallet and assigned meaning to particular colour types so that screens flow much better.

Core Platform Improvements

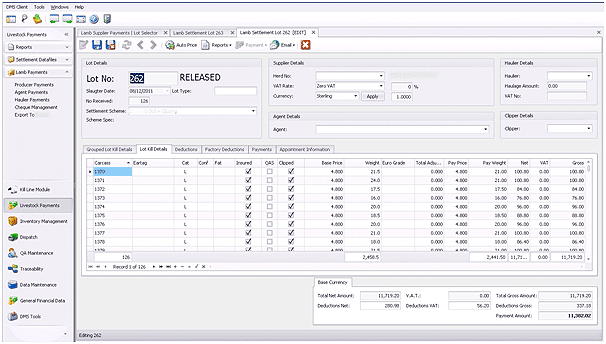

For Version 4.0 we concentrated on improvements to all of our core products.

- UI Clarity. Where it made sense, we reviewed the core UI, as well as reviewing every line of code in order to optimise it, making it leaner and more efficient to execute. We tidied up menu items, iconography etc. in order to improve the ease of use of the EMYDEX system overall.

- Touch Usage Improvements. Particularly in the MDA and SDA, we wanted to improve our touch screen usability. All grids in the MDA use inertial scrolling (like on phones and tablets). This will also be available soon on the PCA (Industrial PC Terminal). We added many more keyboards and popup screens to both the MDA and SDA. Finally we added better controls filtering and sorting on a touch screen.

- Update / Patch improvements. We overhauled our Update and Patch solution. Developers that work with our larger customers will, as of version 4.0, find it easier to patch or update Emydex when required to do so. This improvement should see time saved for our customers as devs can work quicker and easier when patching or updating the system.

Standardisation

Version 4.0 marked the creation of a standardised Emydex industry modules, focussing on the Fish processing industry initially. Efforts to standardise portions of our system have been of benefit to our existing customers too, for example:

- Improvements to the SDA. The SDA has had a UI overhaul to make it easier to work with. Cleaner on screen keyboards and buttons have been added. Performance improvements in core SDA modules exist for all customers on version 4.0

- Cloud Delivery. Our standard system is Cloud Delivered and optionally Cloud Managed, by providing both delivery and management in the cloud we can offer much greater flexibility to our customers in terms of solutions that fit their needs.

- Label Management. As of Version 4.0 Labels can be managed centrally and stored in Emydex. Labels do not have to be stored on a share any longer. This allows labels to be managed on the client and synced to workstations easier than before.

Maturation of MDA

In the last major version release of Emydex we introduced the MDA (Mobile Device Application). The idea of the MDA was to have an app that was lighter than the PCA, could work offline, and would work better with tablet type devices. Version 4.0 brings a number of important changes to our MDA app, including:

- File based SQL backend. This allows much easier management of the local database. There are no specific extras to install or set up and because the whole database exists as a file, it can be sent to us for debug purposes with ease.

- Faster screen load times. Changes and performance improvements to our core have improved our screen loading times on the MDA. We measure 20% improvements in many instances.

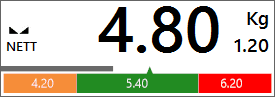

- Weight to Label time improved. The MDA contains an overhauled transaction engine which improves the speed of transactions. This means a faster turnaround time when weighing a box to putting a label on it.

- The MDA now has the ability to use pop up style forms. This means we can make our UI’s less busy going forward and afforded greater ease of use to touch screens. All of our popups are multi-level meaning one popup and sit on top of another. This allows layer of features in ways we could not do before.