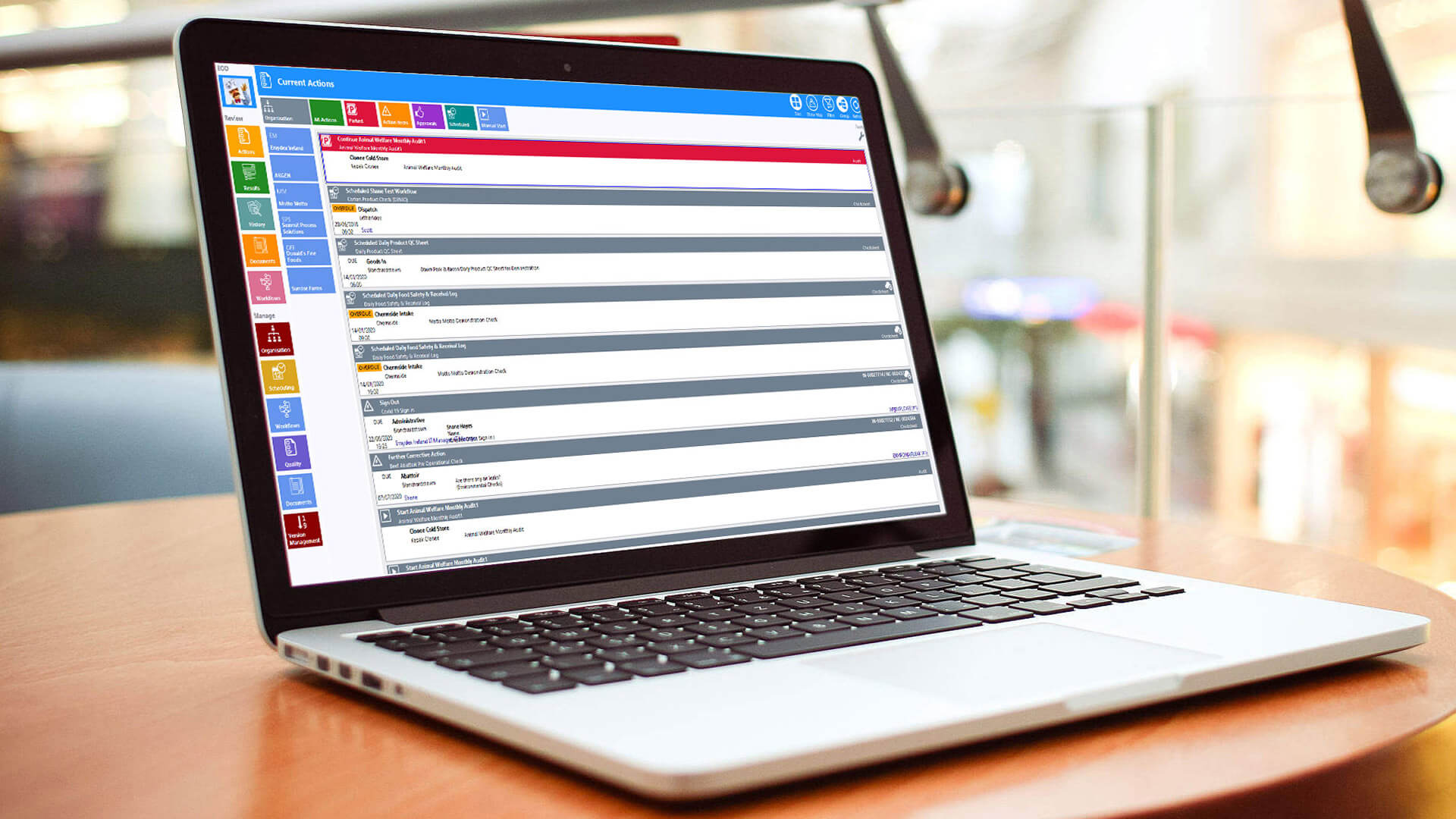

Emydex, a leading provider of software solutions for the meat processing industry, is celebrating its 20th anniversary in 2024.

Over the past two decades, Emydex has been instrumental in transforming the operations of beef processors worldwide.

Ashbourne Meats in Ireland, an Emydex customer for eight years, praised the Emydex team for their reliability, friendliness, and professionalism. Donal Houlihan, Operations Manager, said, “The Emydex team have an excellent understanding of the Meat Industry. The system is extremely user friendly, which allows for a smooth working environment across all our production lines. Their technology constantly meets our needs in an ever-evolving industry.”

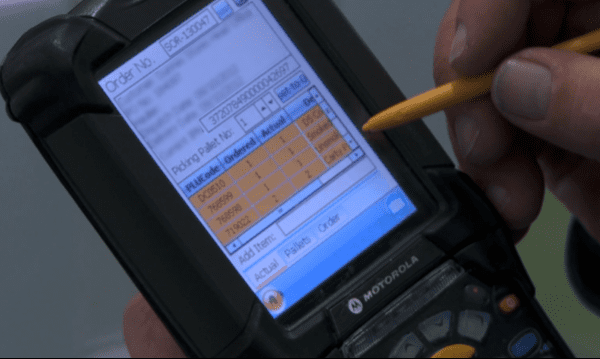

Central Agri Group in Victoria, Australia, has also been an Emydex customer for eight years. The Managing Director, Rami Koyu, commended Emydex for its smooth rollout and the positive response from operators. He said, “The Emydex roll-out was one of the smoothest IT system rollouts I have ever been involved in.”

Dawn Meats Group in Ireland, an Emydex customer for twenty years, praised Emydex for its agility. Shane Slattery, Group CIO, said, “For twenty years Dawn Meats and Emydex have been in a symbiotic partnership, during which time the Emydex solutions have been able to be quickly adapted to changes within both our industry and business.”

Eurofarm Foods in Ireland, an Emydex customer for fourteen years, commended Emydex for its ‘can-do’ attitude as well as excellent helpdesk support. Ciaran Boyle, General Manager, said, “More recently, Emydex were also there to support our business in the immediate aftermath of a cyber-attack on the business in Sept 2021. This was a phenomenal result to say the least.”

Harvey Beef in Western Australia, an Emydex customer for nine years, praised the Emydex team for their willingness to understand their problems and look at solutions. Mike Stephenson, Head of Technology, said, “The team are great to work with and always willing to understand our problems and look at solutions to improve the way our Emydex is integrated with our business.”

Kepak Group in Ireland & UK, an Emydex customer for seventeen years, commended Emydex for its support in their business growth. Jeremy O’Callaghan, Group CIO, said, “Emydex have been an integral part of the system delivery team for Kepak Group for almost two decades, supporting us in our business growth across multiple sites in both Ireland and the UK.”

Liffey Meats in Ireland, a customer operating Emydex in two of its plants, commended Emydex for its ‘can-do’ attitude. Derek McDermott, Chief Financial Officer, said, “Having worked with Dave and his team for the past fourteen years, I can say the key difference with Emydex is their ‘can do’ attitude.”

MeatCo in Namibia, an Emydex customer for thirteen years, praised Emydex for its fit-for-purpose product. Grant Mitchell, IT Manager: Production Systems, said, “Emydex is a Fit for Purpose product, which complements our Business.”

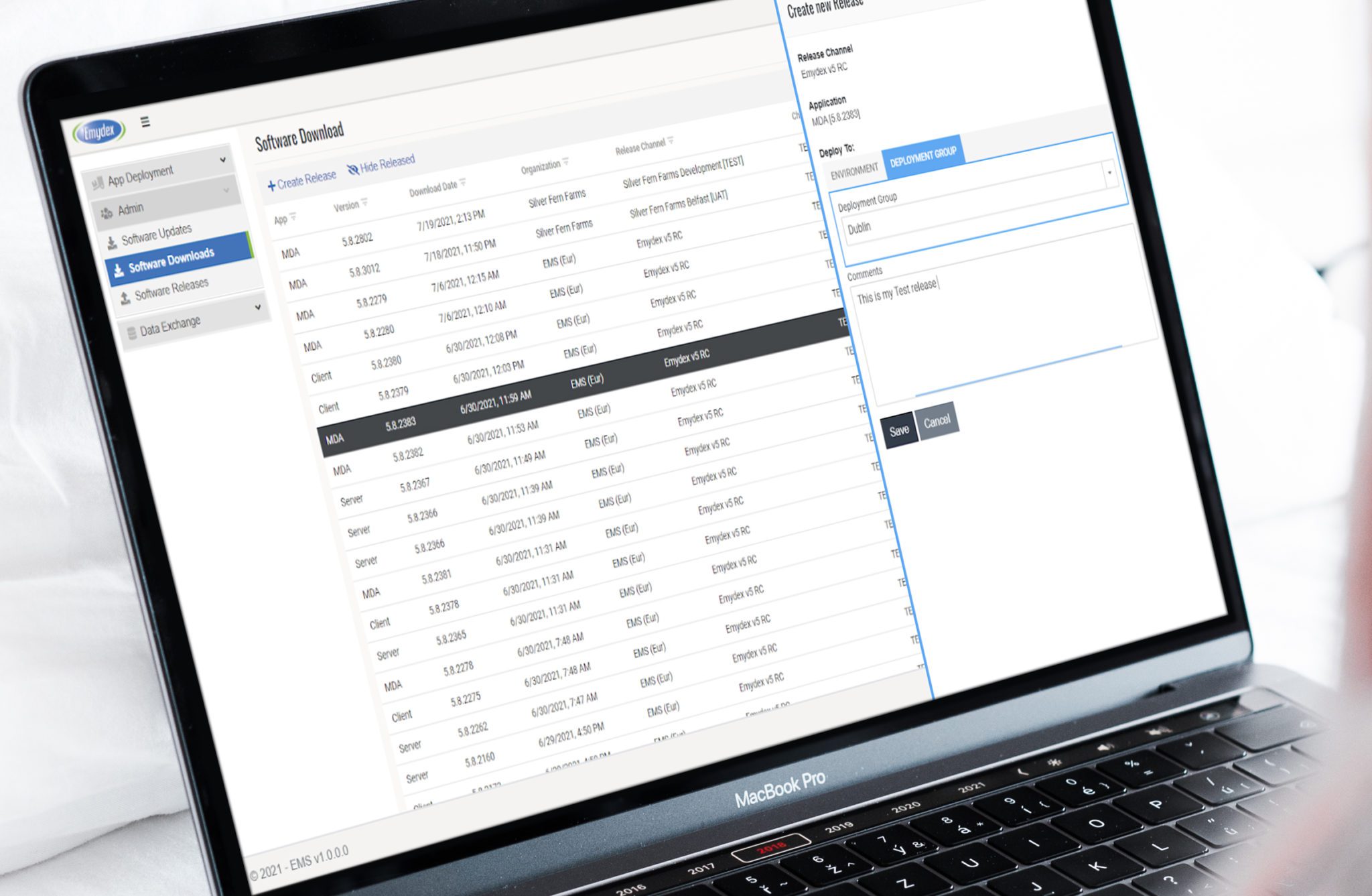

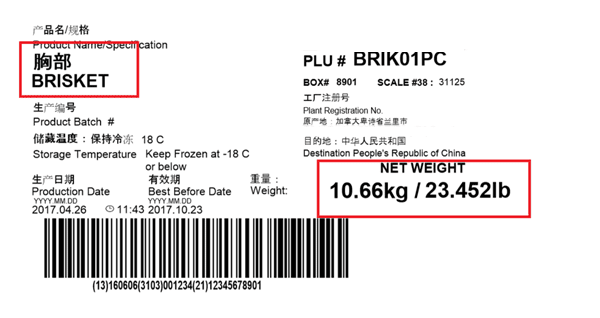

Silver Fern Farms, operating fourteen plants in New Zealand, has been an Emydex customer for four years, currently operating Emydex in two of its plants with further plant rollouts in progress. Matt Ballard, Chief Transformation Officer, highlighted Emydex’s ability to provide greater traceability and process controls, saying, “Emydex has shown it can provide greater traceability and process controls that are positive in meeting Silver Fern Farms needs over the longer term.”

Wilson Hellaby Ltd, with two plants in New Zealand, has been an Emydex customer for three years. Justin Lee, Chief Financial Officer, commended Emydex’s innovative approach to software development, saying, “In both instances we were able to employ Emydex’s innovative approach to software development to solve challenges within our industry where off-the-shelf solutions just don’t exist.”

These testimonials from just ten of Emydex’s global beef customers highlight the significant benefits that Emydex software brings to beef processors, including smooth rollouts, greater traceability, innovative solutions, and excellent support. Between them these customers have been working with Emydex for 119 years collectively between them, across 36 plants.

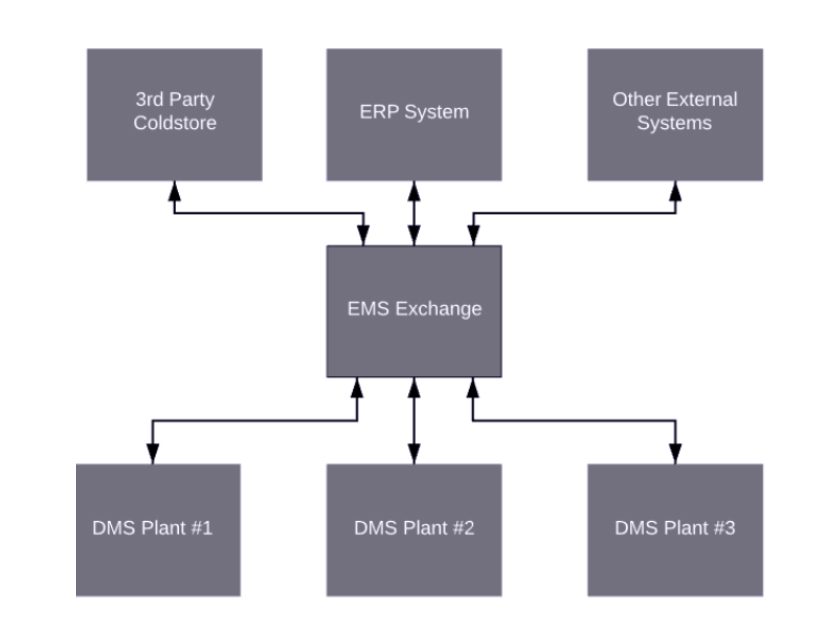

Over the past two years, a dedicated team at Emydex HQ in Dublin, Ireland, has collaborated with numerous longstanding beef processing customer to develop a new Industry Standard software solution for the Beef Processing industry. This project, known as Project Vexillum (which is Latin for ‘Standard’), aims to create a comprehensive, ready-to-use Manufacturing Execution System (MES) tailored for beef processors. The initial rollout of this system will be undertaken by four Emydex beef processing customers, deploying it across more than 20 beef primary processing facilities in Ireland and the UK.

As Emydex celebrates its 20th anniversary, it looks forward to continuing to provide top-notch solutions for the beef processing industry.

If you want to learn more – contact Emydex in any of our global market offices in Ireland, Australia, New Zealand, South Africa, or North America