Building the Future of Beef Processing in Nebraska

Sustainable Beef is a pioneering beef processing company based in North Platte, Nebraska, founded by a visionary group of cattlemen and investors committed to reshaping the beef supply chain. With a strong focus on transparency, efficiency and shared value, the facility is designed to process up to 1,500 cattle per day, provide over 850 jobs, and contribute more than $1.2 billion annually to the Nebraska economy.

This operation sets a new standard in community-driven, modern beef

processing in the United States.

In June 2025, the Emydex team was on site in North Platte, Nebraska to support the go live of Sustainable Beef's state-of-the-art processing facility.

This video captures key moments from the setup, system configuration and collaboration between both teams, marking a major step in Sustainable Beef’s digital transformation.

Challenge

- Difficulty finding a system capable of managing livestock purchasing,payments, and tracking live animals through the facility

- Operations were starting from scratch in a newly built plant with no existing standard procedures

- Most of the workforce had not yet been hired during early implementation stages

- Uncertainty around hardware locations and system touchpoints until late in the project

- Need to comply with US-specific regulations such as the Packers and Stockyards Act and USDA grading

- Requirement for an end-to-end integrated solution that could support a widerange of plant processes

Solution

Emydex partnered closely with Sustainable Beef to design and implement a fully integrated MES and EQMS software solution tailored to the needs of a new and

rapidly evolving plant.

This included:

- Remote workshops to map out the expected future-state of operations

- On-site assessments to define key touchpoints and processes

- Incorporation of U.S. regulatory practices into the platform

- Custom system landscape to integrate with third-party solutions

Our implementation covered every detail, from kill line traceability to plant-floor device integration, delivering full process visibility and real-time control.

Outcome

The successful go-live in June 2025 marked a major milestone in our partnership. Emydex provided hypercare and on-site support during this critical phase, ensuring:

- End-to-end traceability and reporting from day one

- Optimised inventory and quality control operations

- Smooth transition for autonomous system usage

More than just a system implementation, this project laid the foundation for a long-term collaboration. As Sustainable Beef continues to scale its operations, Emydex remains a committed partner in their digital transformation journey, supporting transparency, compliance and operational excellence across every step of the supply chain.

Our News

Industry Updates

-

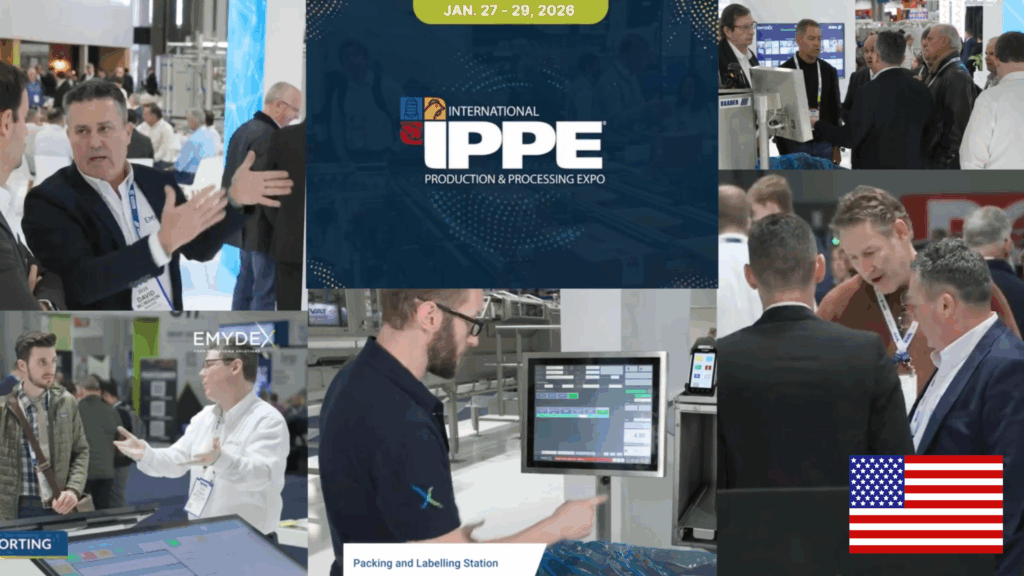

Emydex at IPPE 2026

Our third consecutive year exhibiting poultry processing solutions in partnership with BAADER. Emydex will be exhibiting at IPPE 2026 for the third consecutive year, once…

-

Forresters Chicken: From Paper-Based Processes to Real-Time Visibility with Emydex

Processing over 1.4 million packs of chicken every week and supplying all major UK retailers, Forresters Chicken operates…

-

A new Dawn for Quality systems

Dawn Meats Group, one of Europe’s leading meat processing companies, sought to streamline its factory-floor Quality Management System…

-

Silver Fern Farms welcomes Emydex to Fourth Beef plant in Te Aroha, New Zealand

Silver Fern Farms Expands Emydex Integration in Te Aroha The Silver Fern Farms Emydex implementation continued following successful…

-

Emydex drives Quality to New Heights at Murray’s Chicken in New York

Implementing Emydex at Murray’s Chicken Founded by Murray Bresky in 1992, Murray’s Chicken is dedicated to the local…

-

Forresters Chicken Celebrates a Decade of Quality Management with Emydex

Over the past ten years, Forresters Chicken has leveraged Emydex’s Quality Management system to enhance accuracy, reduce human…