An Emydex customer since 2007, the Dawn Meats Group is one of the largest suppliers of Irish and British Beef, Pork and Lamb in Europe.

Last year (2012) was a milestone year for the group as it secured a 5 year €300m contract for McDonalds, in addition to building a new state of the art patty plant at Carroll’s Cross, Co Waterford, as well as acquiring West Devon Meats in South West England. This follows the group’s acquisition of the Duerden beef abattoir in the Lake District, and the upgrade of their beef slaughter and processing plant in Cardington, UK in 2011.

Dawn Meats began rolling out Emydex’s Production Management software system across the group during 2008. Four years later, Emydex continues to operate as the group standard factory floor data capture and production and traceability reporting system in 11 of the 13 plants within the group including Dawn Meats France.

From Carcass intake, through boning, further processing, packing, box stock and dispatch, Emydex captures and reports on production data, enabling Dawn Meats to analyse and manage their stocks, yields and dispatches, whilst maintaining full food chain traceability.

Commenting on the Emydex system roll-out Shane Slattery, Group IT Manager with Dawn Meats said “Emydex is a central pillar of our strategic IT plan going forward, and our goal now is to concentrate on completing the roll-out of Emydex to our primary processing sites by year end. This plan may seem aggressive, but we believe that it is achievable on account of the inherent flexibility of the core Emydex product to handle any differences in the business processes required in our disparate sites”.

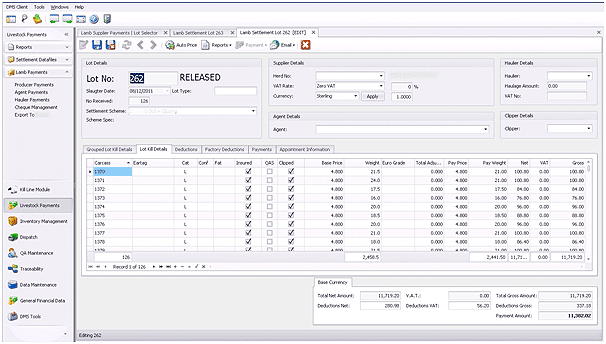

Plans are to complete the Emydex roll-out across the group in 2013, with the implementation of the system at Dawn’s Lamb processing plant in Ballyhaunis in Ireland, as well as the roll-out of Emydex’s kill line & payments systems to all of Dawn’s slaughter plants within the group.

For more information on the Emydex kill line system contact Emydex on +353 1 8855990