The Emydex Electronic Quality Management System (EQMS) has undergone a major redesign and redevelopment over the past 12 months, with significant input from some of Emydex’s largest multi-plant beef, lamb, pork and seafood processors operating in Ireland, the UK, Africa and Australia.

Taking all the learnings and experiences gained from previous Emydex QC system implementations; this latest release of the Emydex QC module is a fully comprehensive and extensive QMS system, designed to cater for the needs of large Enterprise-level food processing organisations.

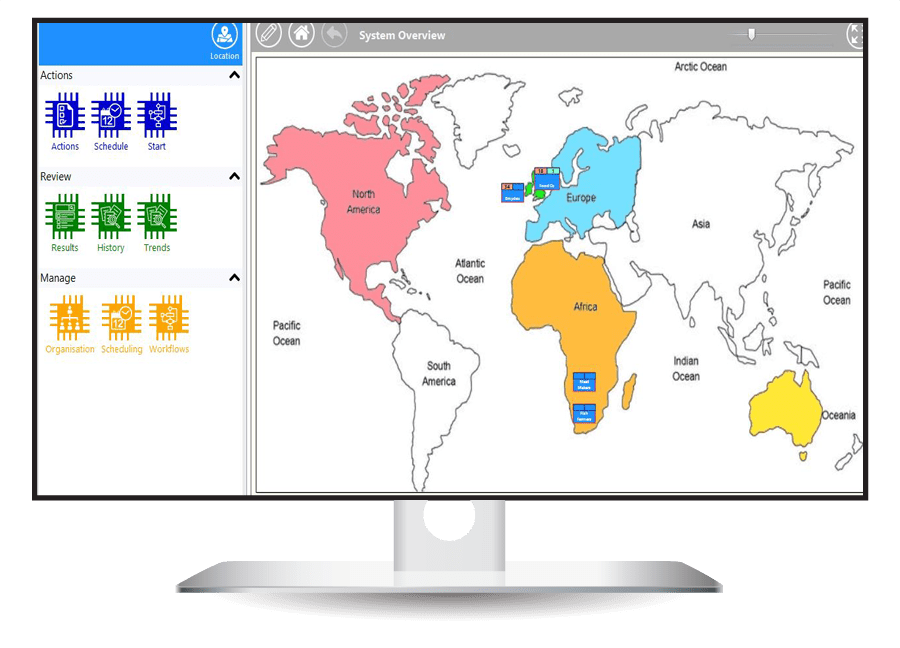

The system is ideally suited to group-level food processors operating different business divisions, spanning different geographies, offering both real-time and accurate reporting on QC activities, at both group and individual plant-level via the Emydex QC cloud-hosted platform.

Maintain a sky-level overview of QC activities across divisions and operations within the organisation, in real-time

Maintain a sky-level overview of QC activities across divisions and operations within the organisation, in real-time

Cloud v On-Premises: In addition to hosting in the cloud, the system can alternately be installed on-premises if required.

Small v Large: It can also cater just as effectively for both small and medium-sized meat, fish and food processing plants, as well as larger production operations.

EMYDEX QUALITY MANAGEMENT SYSTEM DEMO VIDEO

Key features include:

BUILD

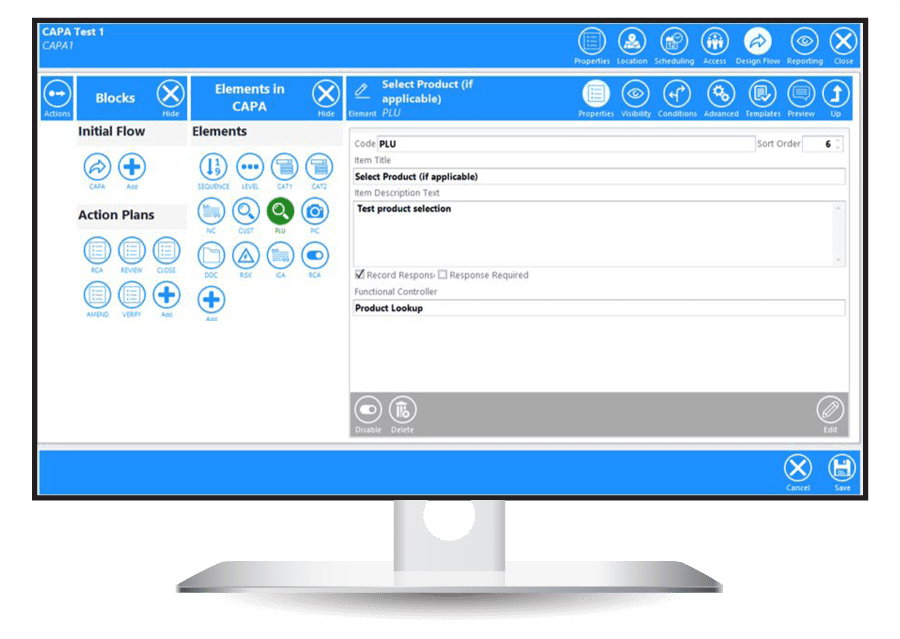

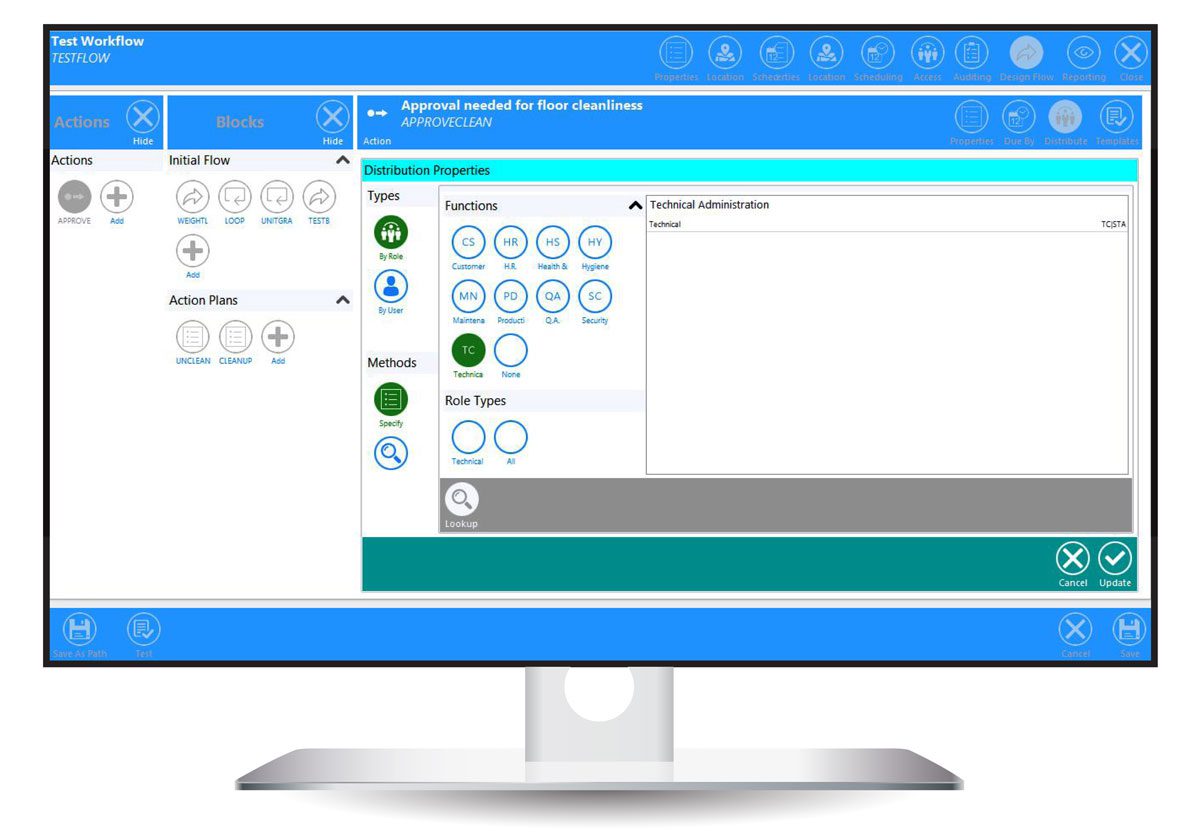

QC Workflow Builder: one of the most significant improvements to the Emydex QMS, is a major design and development effort focussed on developing an easy-to-use, yet comprehensive QC workflow builder tool.

This application allows in-house Technical and QC personnel (non-IT people) to design and build their own Quality workflows in-house, including QC surveys, QC check sheets and quality audits, without the need to involve either Emydex developers or internal IT resources.

The result is an easy-to-use, icon-driven workflow builder application, powered by Question Blocks that can be saved as templates, and re-used from one quality survey to the next.

Workflows can include conditional responses such as ‘if the answer is X do A, if Y then B’, and includes Action Plans such as notifying supervisors, generating follow-up actions, sending emails, reminders, notifications, triggering CAPA workflows etc.

Configure QC workflows from scratch. Determine what questions to ask, and how best to capture the information needed.

Configure QC workflows from scratch. Determine what questions to ask, and how best to capture the information needed.

CAPTURE

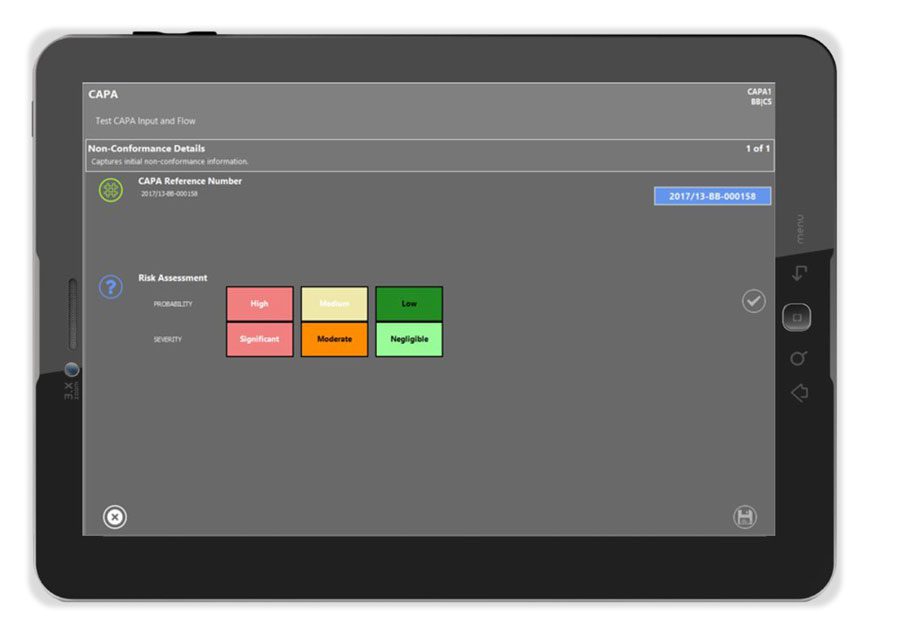

QC Workflow Data Capture: once QC workflows have been designed and tested they can be executed on the factory floor. Workflow surveys can be validated by running them in ‘test mode’ in which case, the test transactions are saved separately from ‘live’ QC data.

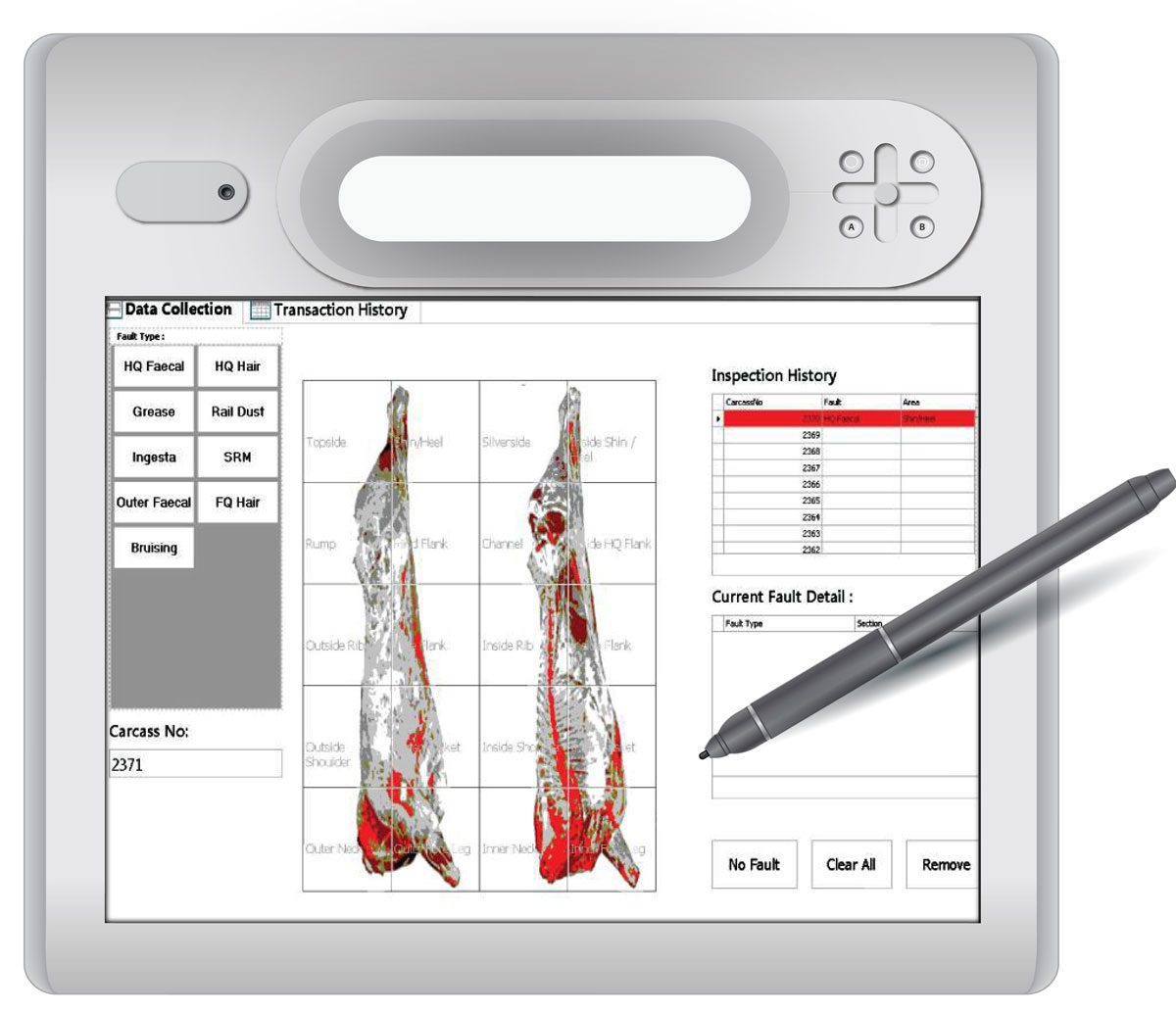

QC data capture can be carried out using a range of data capture hardware devices including existing fixed-position Industrial terminals, rugged tough-books or even low-cost tablet devices running the Windows 10 operating system.

Capture QC data such as CAPA workflows on low-cost tablet devices running Windows 10

Capture QC data such as Product Quality Checks on rugged Toughbook devices for harsh environments

Emydex Production System Look-up & Validation – One major advantage of the Emydex QC module, is that food processors who have also implemented an Emydex Factory Floor Production Control and Traceability reporting system in their operations, can scan product barcodes, retrieve traceability details, and perform validation from the Emydex QC system against production data stored in their Emydex Production system, something not possible with independent 3rd party QC systems.

Kill line QC inspections – logging QC faults against Carcasses within Emydex Production systems

REPORT

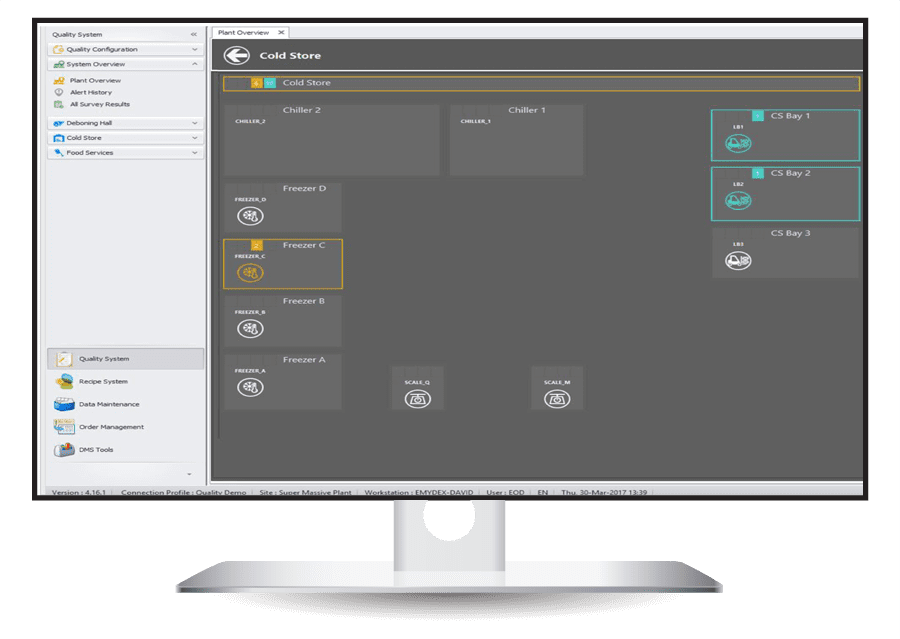

Instant Back-office Reporting via Plant Maps & Dynamic Data Views – whether operating in a single plant or group plant operation, managers and supervisors will have real-time access to QC data captured as it happens.

The QC module plant map drill-downs allow supervisors to ‘manage by exception’ drilling down to the areas where any QC issues or non-conformances are raised, to investigate and raise actions as needed.

Drill-down plant maps enable issues & non-conformances to be identified and actioned quickly

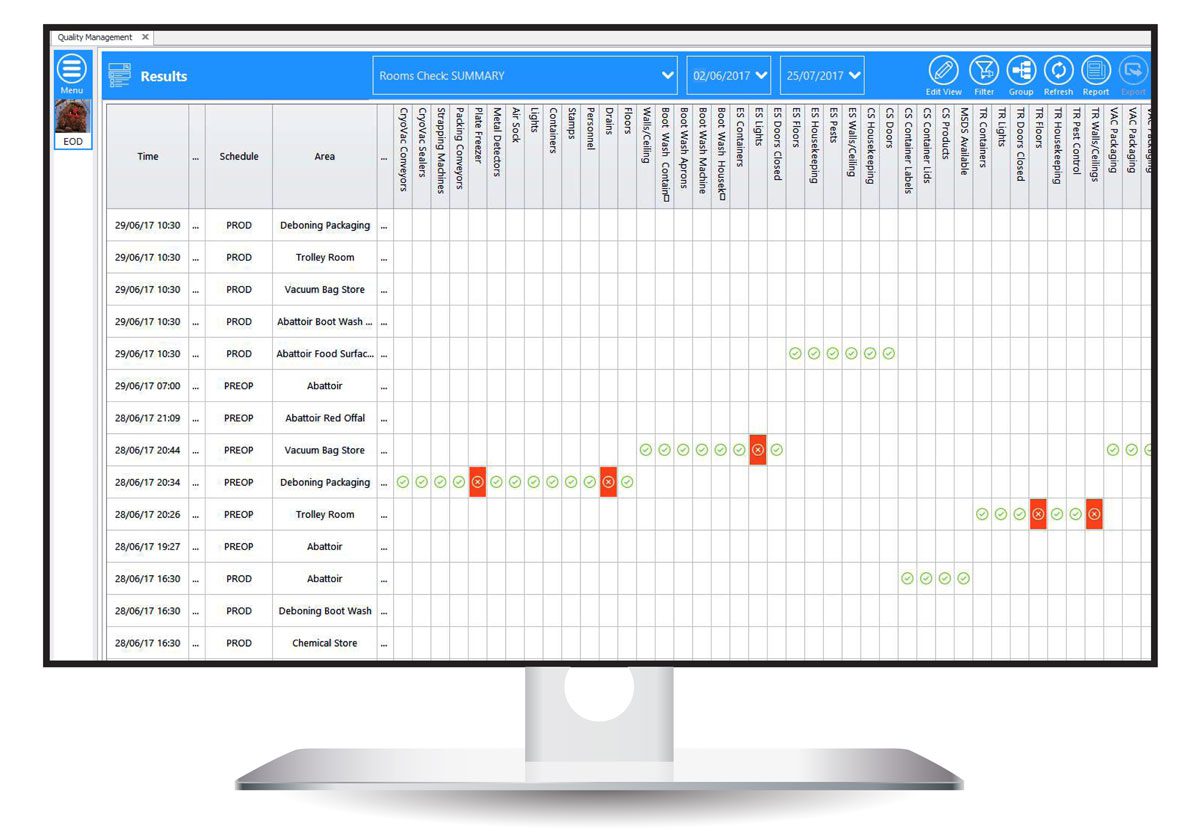

QC Data can also be viewed using Data Grids and Views that can be configured by users themselves, and saved as personal templates; allowing data to be grouped, sorted, filtered, analysed and exported to Word, Excel or Email if needed.

Customise the way you view results, and decide what information you want to see and when

Customise the way you view results, and decide what information you want to see and when

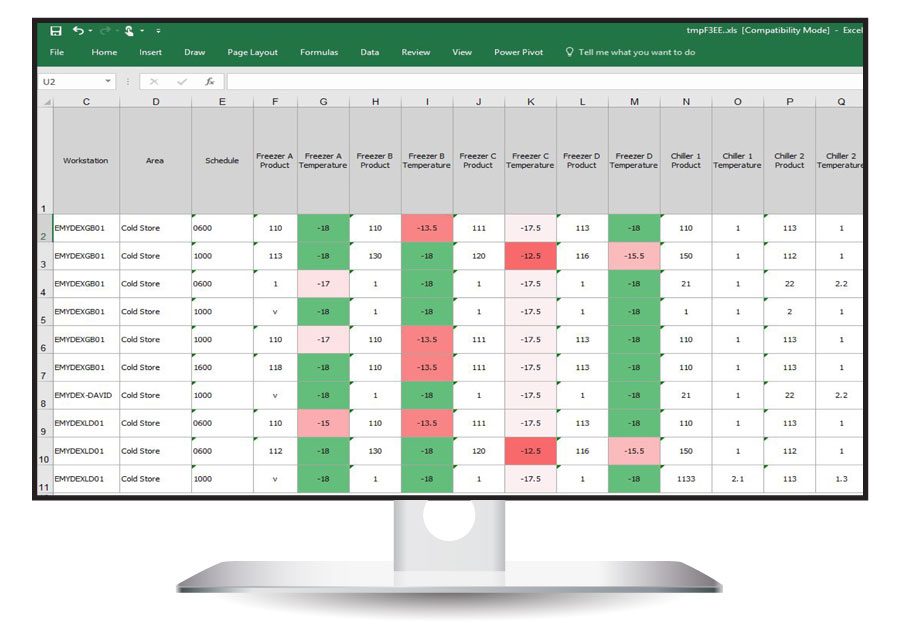

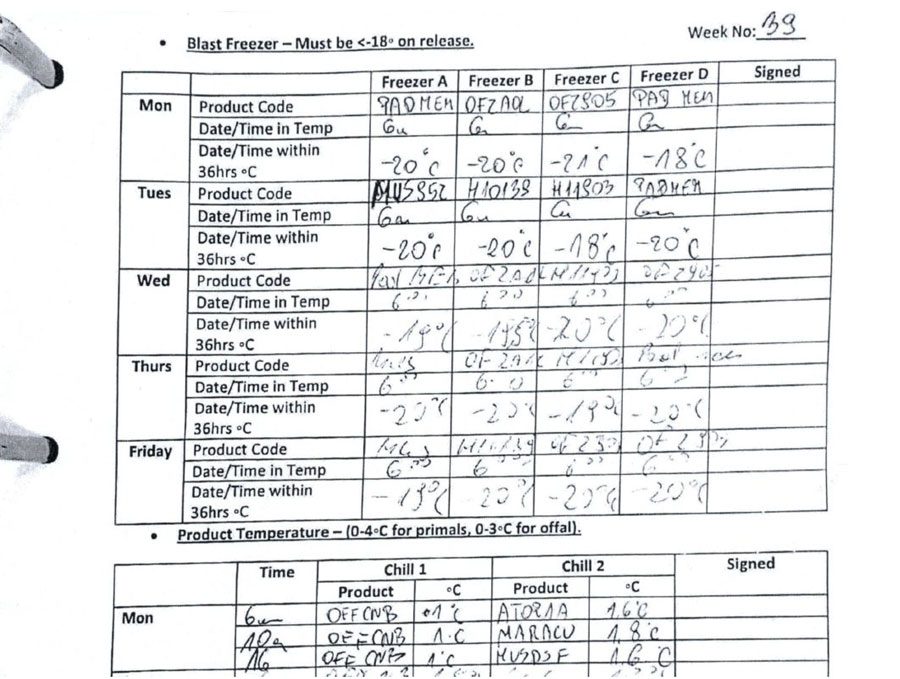

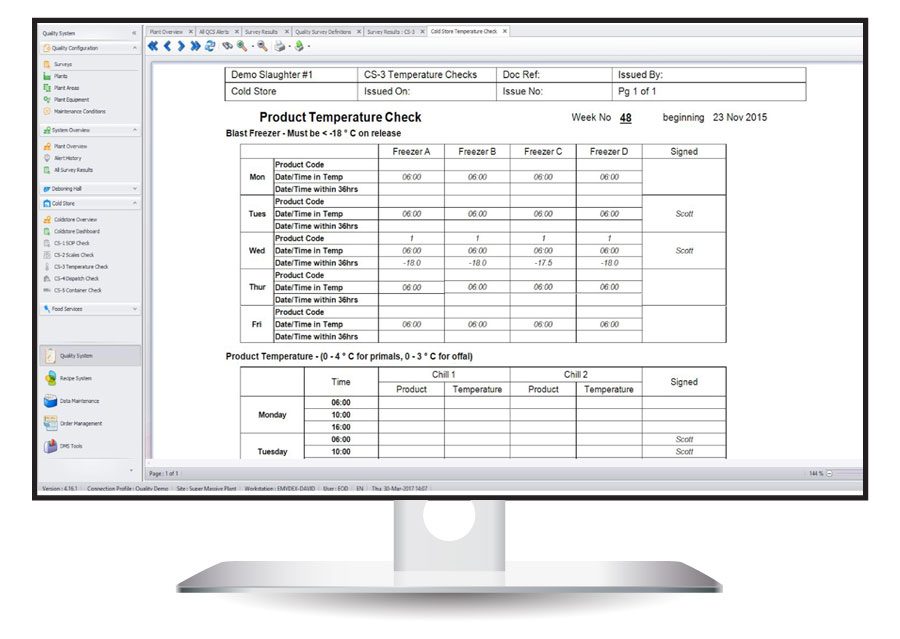

Emydex Report Writer – Emydex’s QC report writing application can also be used to prepare printed reports that can match exactly the format of the original paper-based QC surveys and check-sheets if required.

Emydex Report Writer – Emydex’s QC report writing application can also be used to prepare printed reports that can match exactly the format of the original paper-based QC surveys and check-sheets if required.

Original Paper-based QC Survey

Same QC data presented in similar report format post electronic data capture on an Emydex QC device

Same QC data presented in similar report format post electronic data capture on an Emydex QC device

Other features worth highlighting include:

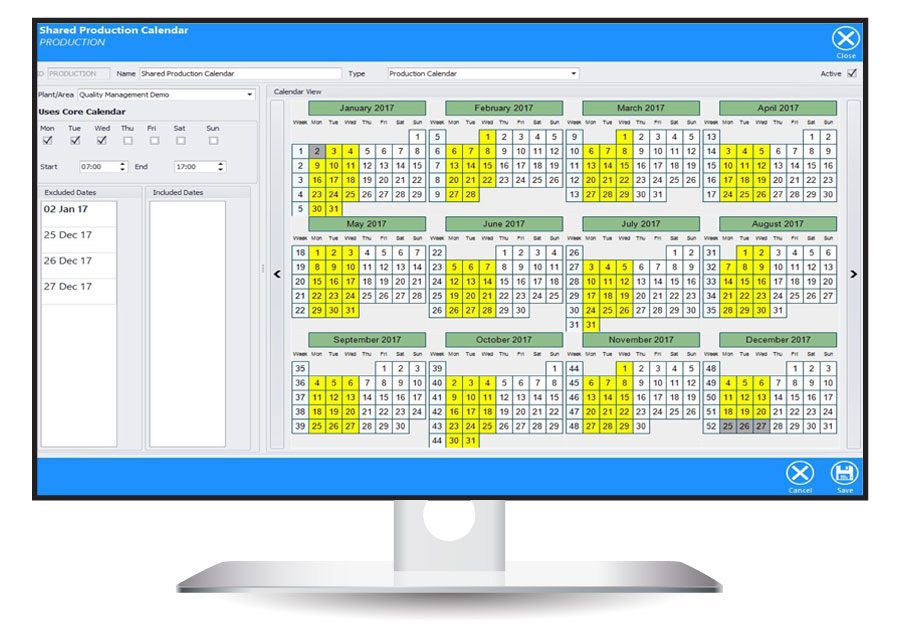

Production Calendars

Create multiple production calendars. Outline schedules relative to hours of operation.

Create multiple production calendars. Outline schedules relative to hours of operation.

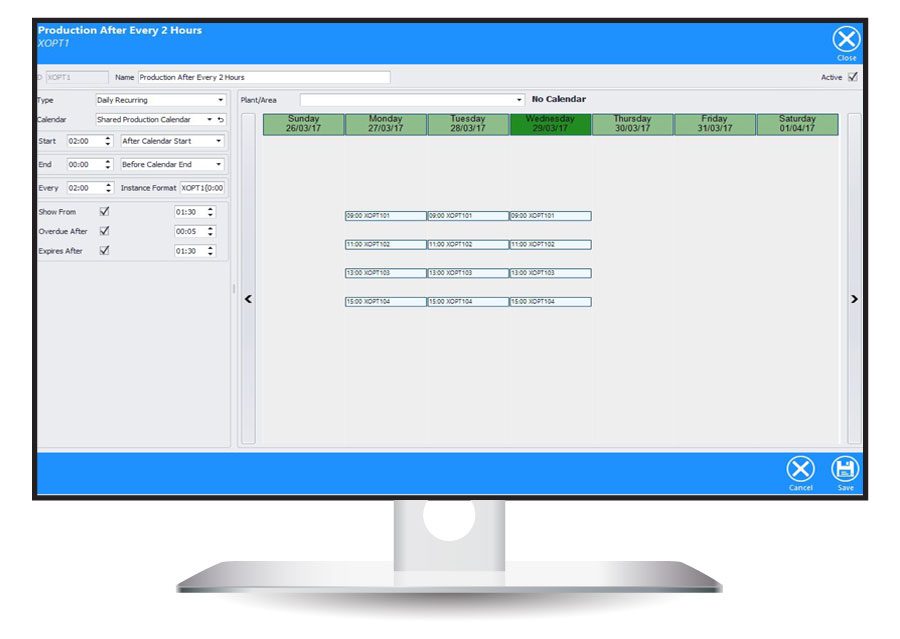

Production Schedules

Create Schedules to control what needs to be done and when? Daily, Weekly, Monthly, and Yearly schedules

(1) Pre-production (2) Post-production or (3) During production at set interval checks – you decide

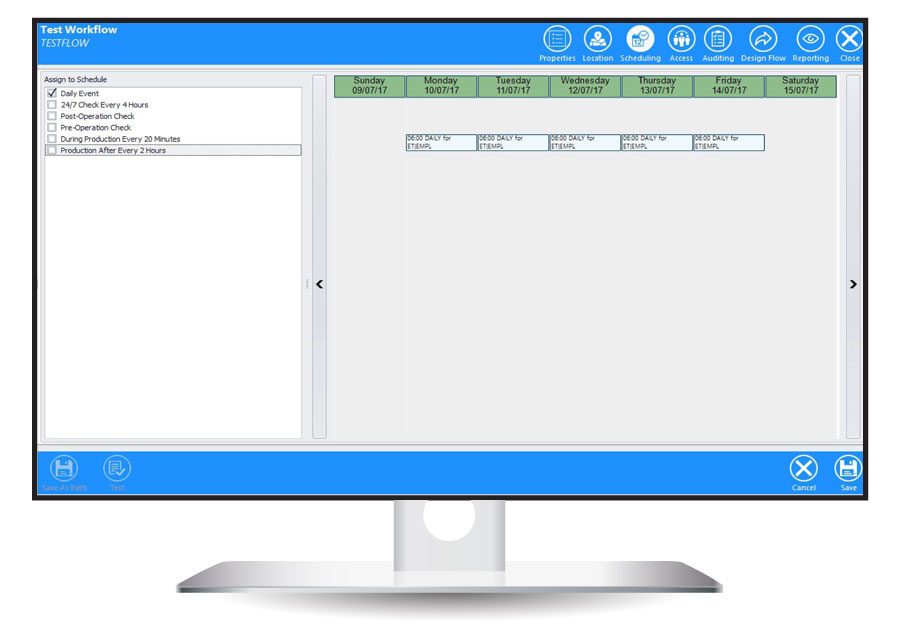

Schedule Workflows

Schedule Workflows with a click of a button. Apply zero, one or many schedules to a workflow as required

Schedule Workflows with a click of a button. Apply zero, one or many schedules to a workflow as required

Roles & Responsibilities

Assign QC Workflows only to those responsible for them. Assign Actions only to those with the authority to complete them.

Assign QC Workflows only to those responsible for them. Assign Actions only to those with the authority to complete them.

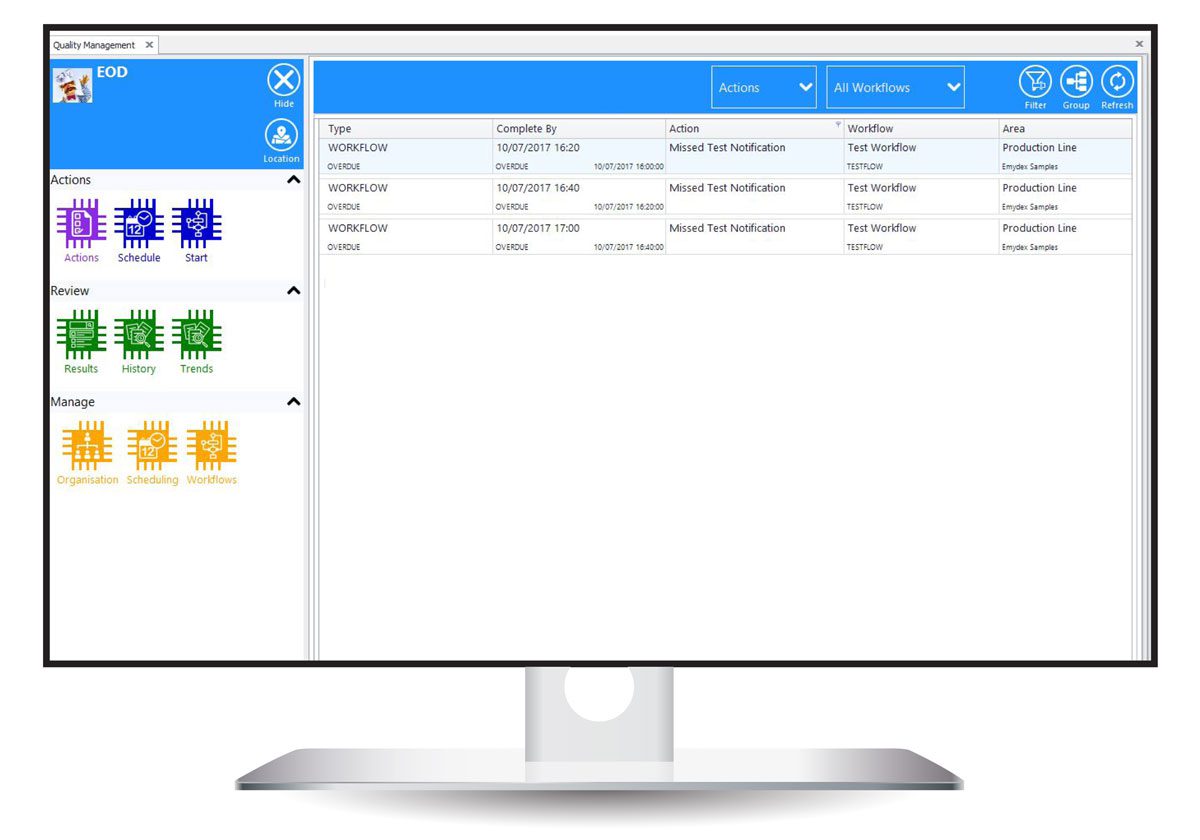

Missed Workflow Notifications

Quality System will track missed Workflows. Automatically notify when a workflow is missing or not completed as scheduled.

Quality System will track missed Workflows. Automatically notify when a workflow is missing or not completed as scheduled.

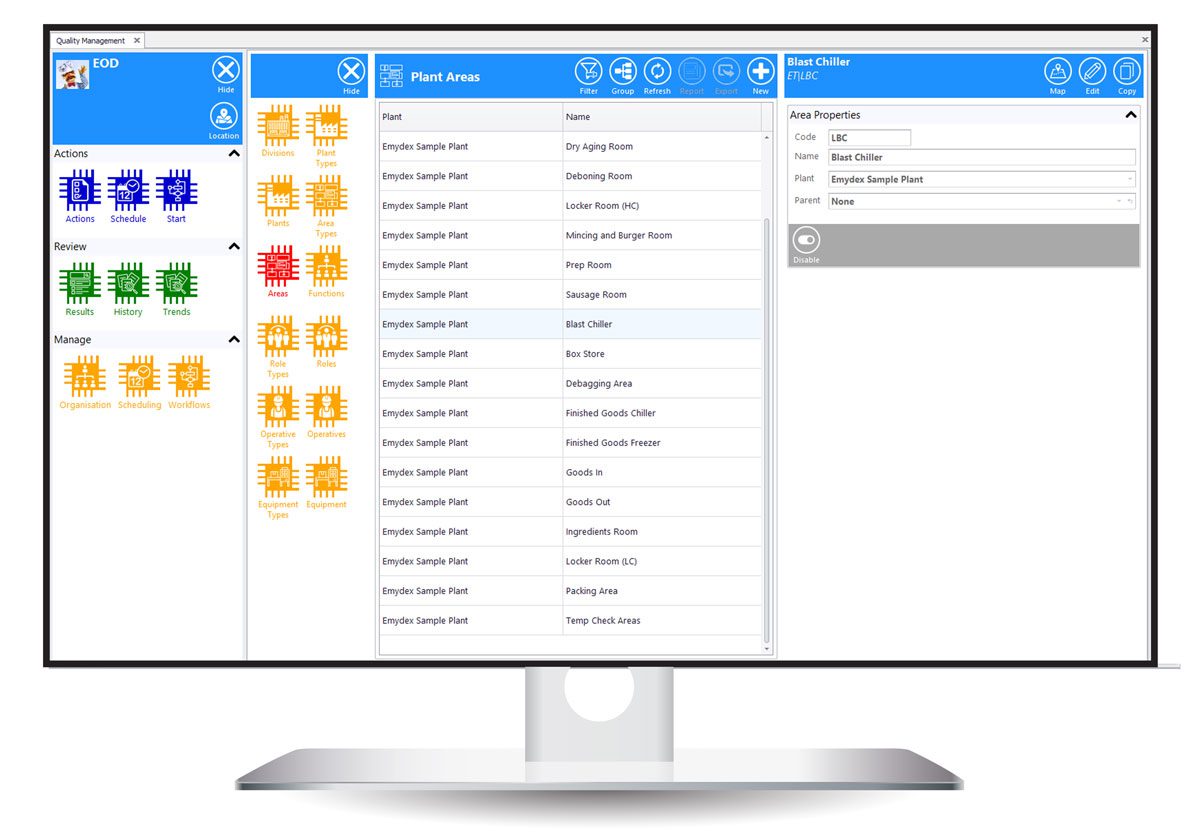

Organisation

Assign QC Workflows to different Plants, Areas and Roles. Track what needs to be done where?

Assign QC Workflows to different Plants, Areas and Roles. Track what needs to be done where?

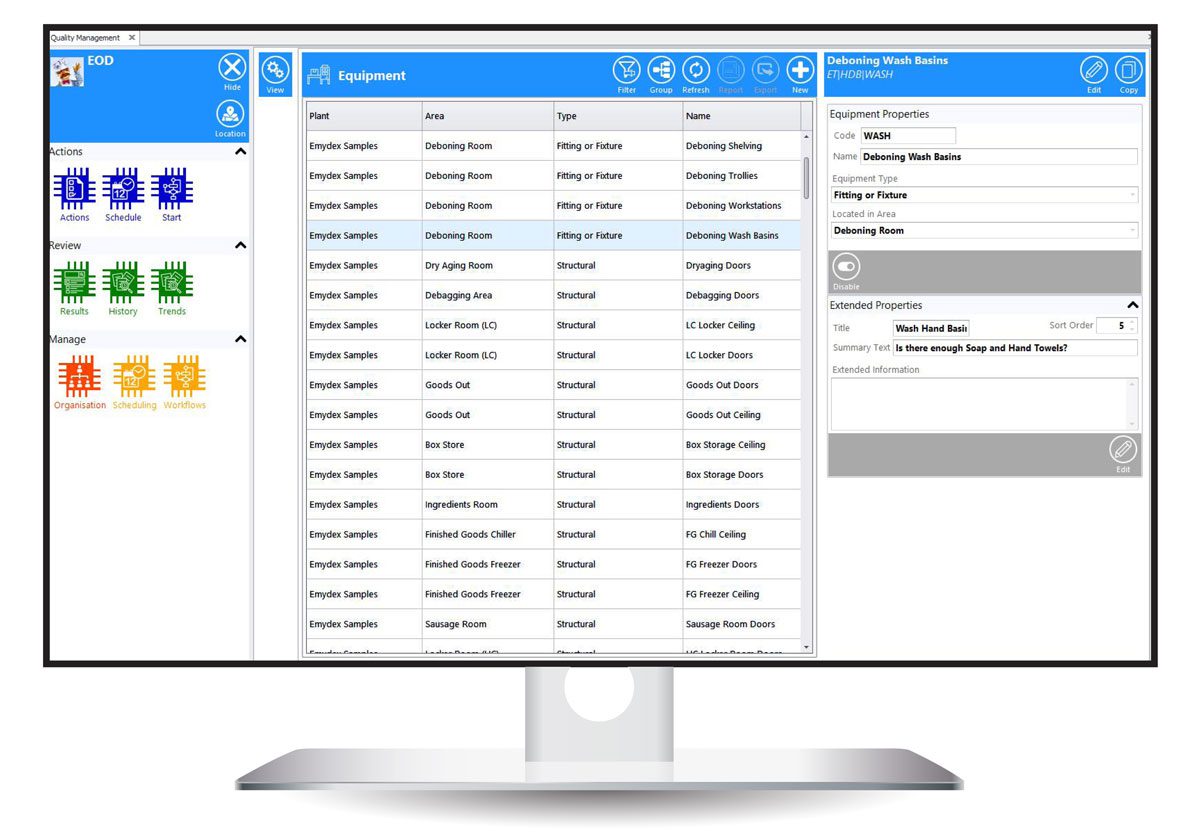

Equipment

Manage Equipment Lists. Create Preventative maintenance quality checks for equipment.

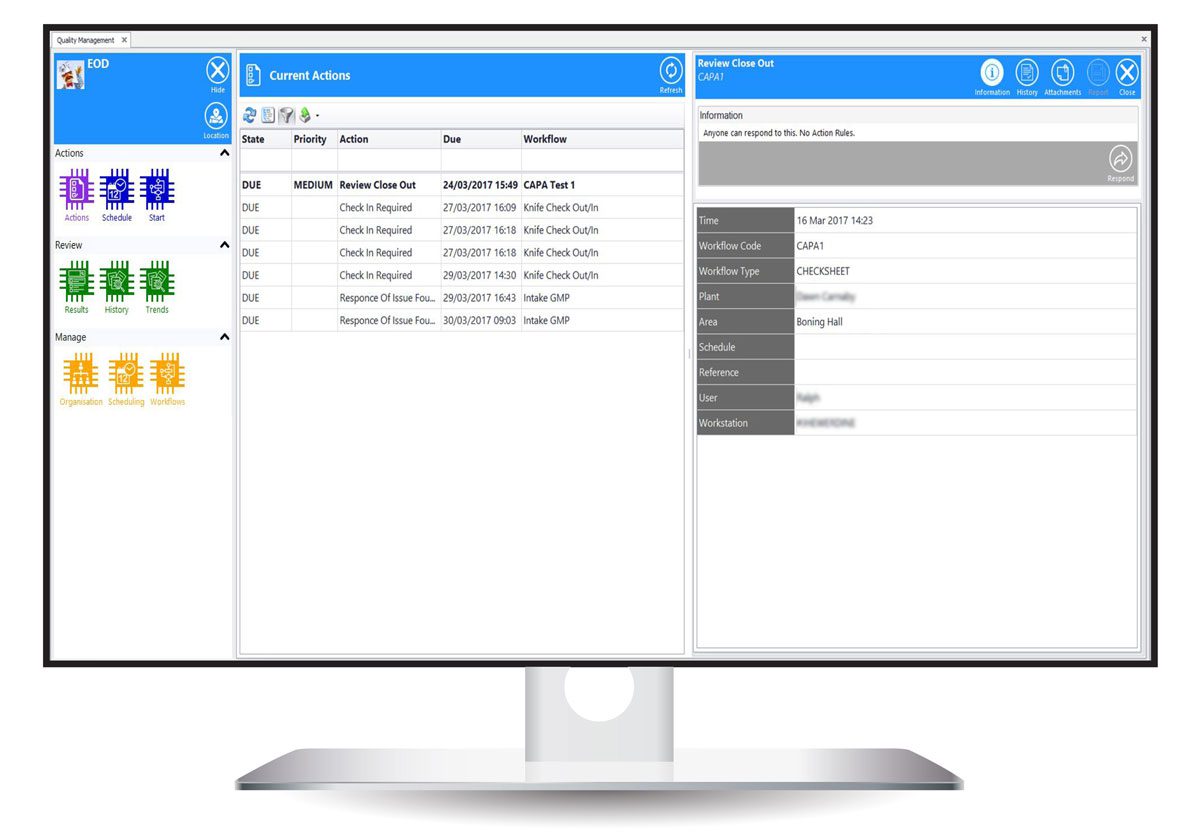

Actions Console

Log into your personal QC Actions console. Track all your Quality System Actions. See only Actions you are responsible for.

Log into your personal QC Actions console. Track all your Quality System Actions. See only Actions you are responsible for.