Packing & Processing Software

Emydex’s Packing & Processing Software is currently operating in over 80 boning halls, filleting rooms and cutting plants operated by leading Meat, Fish and Food processors around the world including Ireland, the UK, mainland Europe, Africa, Australia & North America.

Having first gone live in 2006 in one of Ireland's largest beef and lamb processors Kepak Clonee, today our Packing & Processing software system is in daily operation in numerous Emydex client sites.

Packing & Processing

Benefits of our System

Packing & Processing

System Features

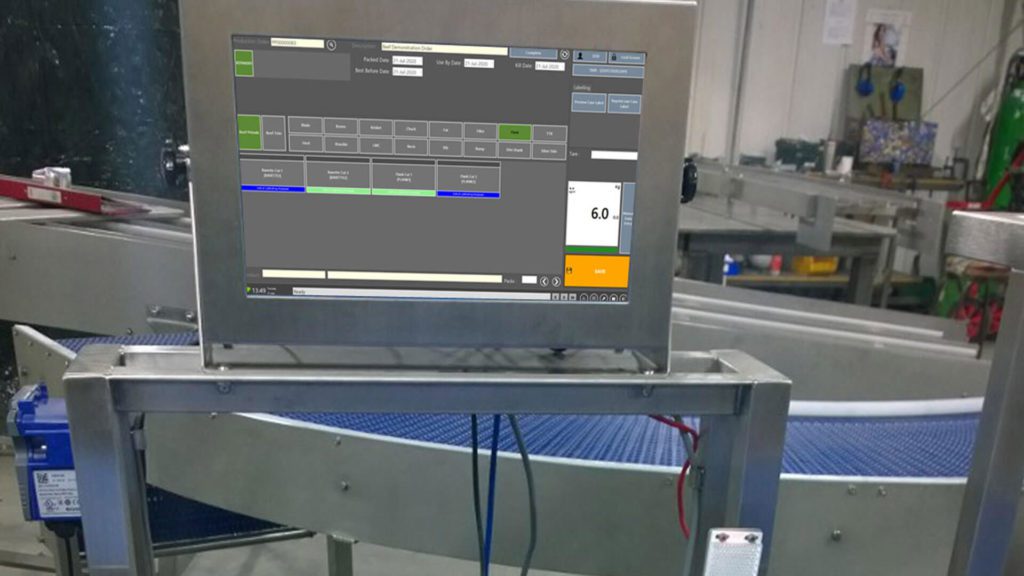

Case Labelling

The Emydex case Labelling functionality is able to pack in many ways to suit your needs, choose to pack to sales orders, direct to pallets or direct to stocks. Configure different terminals in the factory to work differently as required.

Pack Labelling

The Emydex pack Labelling functionality allows customers to weigh individual packs of meat and apply labels. These packs can be allocated directly to a case to create stock.

Bulk Label Printing

The Emydex bulk label printing allows customers to print batches of case or pack/insert labels. This removes the need for other 3rd party printing applications to print labels and also reduces human error as all information is fed from Emydex.

Rework Processing

The Emydex rework processing allows customers to maintain traceability of reworked product and measure yields for this process.

Label Designer

Emydex use world-class label design and printing software – Nice label. The nice label software is fully embedded within the Emydex application which means end users can complete all label design tasks without leaving the Emydex application. Labels can be managed at a site level or using the Enterprise management system.

Automatic Case Labelling

Emydex system is able to integrate to automatic case Labelling machines to reduce labor and prevent operator error. Emydex can cater for different Automatic case labelling setups.

WPL Integration

Emydex system is able to integrate to weigh price Labelling machines to start and stop production jobs, including sending batch numbers, order quantities etc. Emydex is also able to control master data such as descriptions, allergens, dates, labels as well as receive processing statistics such as reject rates, efficiency etc. meaning customers can complete all production reporting in one system.

Designed for your industry

Our software modules

The Emydex suite of software includes a collection of independent standalone software modules designed to manage and control a particular stage of the Food Production Process e.g. Kill Line & Payments.

Each modules sits on top of the core platform, and can plug seamlessly into any other module. The full suite of modules cover all aspects of Food production from factory door-to-door.

Emydex Explained

Our software provides real-time and accurate reporting of Production, Yields, Stocks, Quality and Traceability

Our News

Industry Updates

Emydex 20 years – Clogherhead Co-op

Clogherhead Co-op Seafood Primal Processor, 1 Co-operative plant, 12 trawlers, Ireland Emydex customer from 2014 – 2024 (10…

Find Out MoreEmydex 20 years – Central Agri Group

Central Agri Group Beef Primal Processor1 Plant in Victoria, Australia Emydex customer from 2016 – 2024 (8 years)…

Find Out MoreEmydex 20 years – Silver Ferns Farms

Silver Fern Farms Beef & Lamb Primal Processor 14 plants, New Zealand Emydex customer from 2010 – 2024…

Find Out MoreEmydex 20 years – Wilson Hellaby Ltd

Wilson Hellaby Ltd Beef & Lamb Primal Processor 2 plants, New Zealand Emydex customer from 2015 – 2024 (9 years)…

Find Out MoreEmydex 20 years – QK Coldstores

QK Coldstores (Pty) Ltd Coldstore, 1 plant, South Africa Emydex customer from 2017 – 2024 (7 years) “We are delighted…

Find Out MoreEmydex 20 years – Canfisco

Canadian Fishing Company (Canfisco) Seafood Processor, 4 plants, British Columbia, Canada Emydex customer from 2017 – 2024 (7…

Find Out MoreEmydex 20 years – Ashbourne Meats

Ashbourne Meats Beef Primal Processor, 2 plants in Ireland Emydex customer from 2016 – 2024 (8 years) “Ashbourne…

Find Out MoreEmydex 20 years – Harvey Beef

Harvey Beef Beef Primal Processor 1 Plant in Harvey, Western Australia Emydex customer from 2015 – 2024 (9…

Find Out More